If you’re wondering whether CEM-1 is the right material for your next electronics project, the short answer is: it depends on your project’s needs. CEM-1 is a cost-effective PCB material ideal for single-layer PCB projects and budget-friendly designs, especially for hobbyists and DIY enthusiasts. However, it comes with limitations, such as being unsuitable for multi-layer boards or high-performance applications. In this guide, we’ll dive deep into CEM-1 PCB applications, its benefits, drawbacks, and how it fits into cost-effective electronics projects. By the end, you’ll have a clear idea of whether CEM-1 is the best choice for your work.

What Is CEM-1 PCB Material?

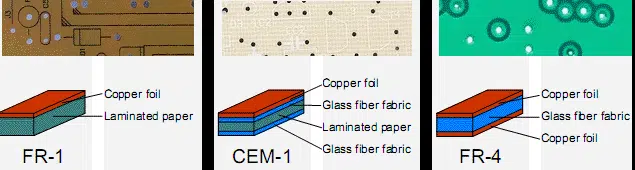

CEM-1, short for Composite Epoxy Material-1, is a type of PCB substrate commonly used in the electronics industry. It’s made from a combination of woven glass fabric and a paper-based core, bonded together with epoxy resin. This structure gives CEM-1 a balance of affordability and decent electrical performance, making it a popular choice for simpler designs.

Unlike more advanced materials like FR-4, which is often used for multi-layer boards, CEM-1 is primarily designed for single-layer PCB projects. Its composition makes it less robust in terms of thermal and mechanical properties, but it remains a go-to option for low-cost applications. For electronics enthusiasts and hobbyists looking for DIY PCB materials, CEM-1 offers an accessible entry point without breaking the bank.

Key Characteristics of CEM-1 PCB Material

Before deciding if CEM-1 is right for your project, it’s important to understand its properties. Here are the main characteristics that define this material:

- Cost-Effectiveness: CEM-1 is significantly cheaper than higher-grade materials like FR-4. This makes it ideal for budget-conscious hobbyists working on cost-effective electronics projects.

- Single-Layer Compatibility: CEM-1 is specifically suited for single-sided boards, where components are mounted on one side, and traces are routed on the other.

- Electrical Performance: It offers stable electrical insulation with a dielectric constant typically around 4.5-5.0, suitable for low-frequency applications.

- Thermal Resistance: CEM-1 has a lower glass transition temperature (Tg) of about 110-130°C compared to FR-4’s 135-180°C, meaning it’s less suited for high-heat environments.

- Mechanical Strength: While it’s durable enough for basic projects, CEM-1 is not as strong as other laminates and can be prone to cracking under stress.

These traits make CEM-1 a practical choice for many DIY enthusiasts, but they also highlight its limitations, which we’ll explore later.

CEM-1 PCB Applications: Where It Shines

CEM-1 is widely used in scenarios where cost and simplicity take priority over advanced performance. Here are some common CEM-1 PCB applications that electronics enthusiasts and hobbyists can consider:

1. Single-Layer PCB Projects

CEM-1 is almost exclusively used for single-layer PCB designs. These are boards with conductive traces on just one side, often used in basic circuits. For hobbyists building simple LED circuits, timers, or small power supplies, CEM-1 provides a reliable and affordable base material. Its compatibility with single-sided designs makes it perfect for prototyping and learning the basics of PCB design.

2. Cost-Effective Electronics Projects

If you’re working on a tight budget, CEM-1 is a fantastic option. It’s commonly used in low-cost consumer electronics like calculators, remote controls, and basic toys. For DIY projects where minimizing expenses is key—such as creating a custom guitar pedal or a small sensor module—CEM-1 helps keep material costs down without sacrificing basic functionality.

3. Educational and Experimental Designs

For students and beginners in electronics, CEM-1 is often the material of choice for learning purposes. Its low cost allows for experimentation without the fear of wasting expensive materials. Whether you’re etching your first PCB at home or testing a new circuit idea, CEM-1 offers a forgiving platform to build your skills.

CEM-1 PCB Limitations: Know Before You Choose

While CEM-1 has its advantages, it’s not without drawbacks. Understanding these CEM-1 PCB limitations is crucial, especially for hobbyists who might push the material beyond its intended use. Here are the key constraints to keep in mind:

1. Limited to Single-Layer Designs

The most significant limitation of CEM-1 is that it’s only suitable for single-layer boards. If your project requires multiple layers for complex routing or high-density components, CEM-1 won’t work. This restricts its use to basic designs and excludes it from advanced applications like smartphones or high-speed digital circuits.

2. Lower Thermal and Mechanical Durability

CEM-1 doesn’t handle heat or physical stress as well as other materials. With a lower Tg value, it can deform or degrade under high temperatures, making it unsuitable for power-intensive projects or environments with significant thermal cycling. Mechanically, it’s more brittle and can crack if mishandled or subjected to vibration.

3. Not Ideal for High-Frequency Applications

For projects involving high-frequency signals, such as RF circuits or fast digital systems, CEM-1 falls short. Its dielectric properties aren’t optimized for maintaining signal integrity at higher frequencies, often leading to signal loss or interference. If your project involves speeds above a few megahertz, you’ll need a different material.

4. Limited Chemical Resistance

CEM-1 is more susceptible to damage from chemicals and moisture compared to other laminates. This can be a concern for projects exposed to harsh environments or during DIY etching processes where prolonged exposure to chemicals might degrade the board.

These limitations make it clear that while CEM-1 is excellent for simple, low-cost projects, it’s not a one-size-fits-all solution. Hobbyists need to weigh these constraints against their project goals.

Comparing CEM-1 to Other DIY PCB Materials

To better understand if CEM-1 is right for you, let’s compare it to other common PCB materials that hobbyists might consider for DIY projects. This will help highlight where CEM-1 stands in terms of cost, performance, and application.

- CEM-1 vs. Higher-Grade Composites: Higher-grade materials like CEM-3 or other composites offer better thermal and mechanical properties and can support multi-layer designs. However, they come at a higher cost, often unnecessary for simple single-layer projects.

- CEM-1 vs. Phenolic Boards: Phenolic boards, often used in the cheapest electronics, are even less expensive than CEM-1 but lack durability and electrical performance. CEM-1 provides a better balance of cost and reliability for most hobbyist needs.

For most DIY enthusiasts working on single-layer PCB projects, CEM-1 strikes a sweet spot between affordability and functionality. However, if your project demands more layers or operates in extreme conditions, you’ll need to explore other options.

Is CEM-1 Right for Your Project? Key Decision Factors

Deciding whether to use CEM-1 for your next project comes down to a few critical factors. Use this checklist to evaluate if it matches your needs:

- Project Complexity: Is your design a single-layer board? If yes, CEM-1 is likely a good fit. If you need multiple layers, look elsewhere.

- Budget Constraints: Are you prioritizing cost over performance? CEM-1 is one of the most affordable options for cost-effective electronics projects.

- Operating Environment: Will your board be exposed to high heat, moisture, or mechanical stress? If so, CEM-1 might not hold up.

- Signal Requirements: Does your project involve high-frequency signals or fast data rates? If yes, CEM-1’s dielectric properties may cause issues.

By assessing these aspects, you can determine if CEM-1 aligns with your project goals. For many hobbyists working on simple circuits or learning the ropes of PCB design, it’s often the perfect starting point.

Tips for Working with CEM-1 in DIY Projects

If you’ve decided that CEM-1 is the right material for your project, here are some practical tips to get the most out of it while avoiding common pitfalls:

- Handle with Care: CEM-1 is more brittle than other materials. Avoid excessive bending or rough handling during assembly to prevent cracks.

- Keep It Cool: Design your circuit to minimize heat buildup. Use heat sinks or spacing for components that generate significant heat to protect the board.

- Protect from Moisture: If your project might be exposed to humidity, consider applying a conformal coating to shield the board from moisture damage.

- Plan Simple Layouts: Since CEM-1 is limited to single-layer designs, keep your circuit layout straightforward. Avoid overcrowding components or traces to ensure reliability.

- Test Before Scaling: For experimental designs, build and test a small prototype on CEM-1 to confirm it meets your needs before committing to larger production.

Following these guidelines will help ensure a smoother experience when using CEM-1 for your DIY PCB materials and projects.

Conclusion: Making the Right Choice with CEM-1

CEM-1 is a valuable option for electronics enthusiasts, especially those focused on single-layer PCB projects and cost-effective electronics projects. Its affordability and ease of use make it a favorite among hobbyists and DIYers looking for reliable yet budget-friendly materials. However, its limitations—such as suitability only for single-layer designs, lower thermal resistance, and inadequate performance for high-frequency applications—mean it’s not ideal for every scenario.

By carefully evaluating your project’s requirements, from complexity and budget to environmental conditions, you can decide if CEM-1 is the right fit. For many starting out or working on simple designs, it offers an excellent balance of cost and functionality. With the insights provided in this guide, you’re well-equipped to make an informed decision and tackle your next electronics project with confidence.