In the fast-evolving world of warehouse automation, energy efficiency is key to keeping operations smooth and cost-effective. How can PCB design play a role in powering these systems? The answer lies in creating high-efficiency circuits tailored for automation needs, focusing on minimizing power loss, managing heat, and ensuring reliable energy transfer. This blog dives deep into the essentials of PCB design for warehouse automated guided vehicle charging, high-efficiency PCB power supplies for automation, and other critical aspects to help engineers build systems that power the future of logistics.

Why PCB Design Matters in Warehouse Automation

Warehouse automation relies on technologies like automated guided vehicles (AGVs), robotic arms, and conveyor systems, all of which need consistent and efficient power. Poorly designed printed circuit boards (PCBs) can lead to energy waste, overheating, or system failures, costing time and money. A well-designed PCB, on the other hand, ensures optimal power delivery, reduces energy loss, and extends the lifespan of automation equipment.

In this post, we’ll explore how to design PCBs specifically for warehouse energy systems, focusing on practical tips and technical insights. Whether you’re working on charging solutions for AGVs or power supplies for robotic systems, these strategies will help you achieve better efficiency and reliability.

Key Elements of PCB Design for Warehouse Automated Guided Vehicle Charging

AGVs are the backbone of modern warehouses, transporting goods with precision and speed. However, their charging systems must be efficient to avoid downtime. PCB design for warehouse automated guided vehicle charging focuses on delivering high current with minimal loss while ensuring safety and durability.

1. High-Current Handling: AGV charging stations often deal with currents ranging from 10A to 50A or more, depending on battery size. To handle this, use wider traces (at least 0.5mm per 1A of current as a general rule) and thicker copper layers (2oz or higher) to reduce resistance and prevent overheating.

2. Voltage Regulation: Maintaining stable voltage is critical to avoid damaging batteries. Incorporate voltage regulators and feedback loops on the PCB to keep output within a tight range, such as 24V ±0.5V for many AGV systems.

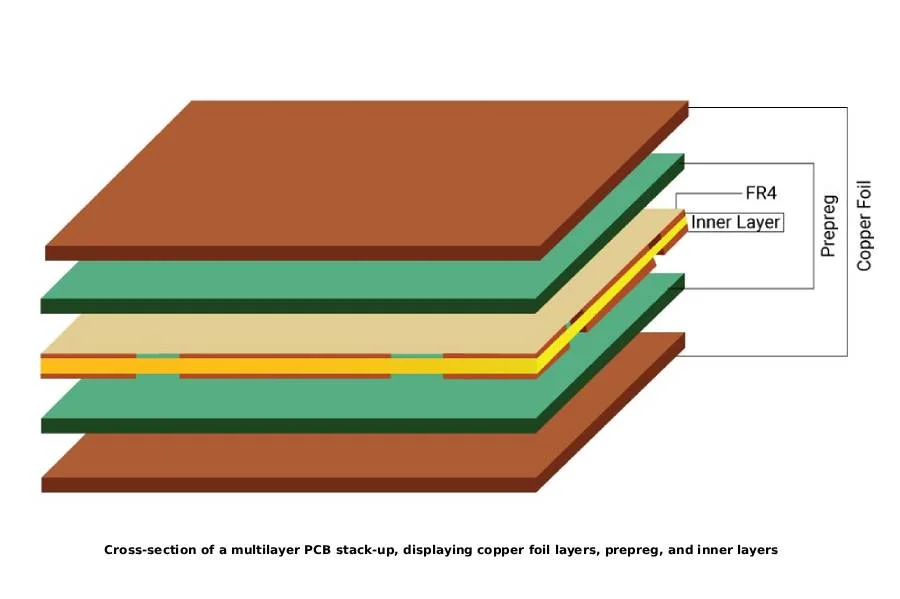

3. Compact Layout: Space is often limited in charging modules. Use multilayer PCBs to stack components and traces, ensuring a compact design without sacrificing performance. Keep high-current paths short to minimize voltage drops.

By focusing on these elements, engineers can create charging systems that keep AGVs running longer with less energy waste, directly impacting warehouse productivity.

Creating High-Efficiency PCB Power Supplies for Automation

Power supplies are the heart of any automated system, converting input power into usable forms for motors, sensors, and controllers. High-efficiency PCB power supplies for automation are essential to reduce energy costs and improve system reliability in warehouses.

1. Switch-Mode Power Supplies (SMPS): Unlike linear regulators, SMPS designs achieve efficiencies of 85-95% by minimizing heat loss. Use components like MOSFETs with low RDS(on) values (e.g., 10mΩ or less) to reduce switching losses.

2. Component Selection: Choose capacitors and inductors with low equivalent series resistance (ESR), such as ceramic capacitors with ESR under 50mΩ, to improve efficiency in DC-DC converters commonly used in automation.

3. Feedback and Control: Integrate precise feedback circuits using ICs with low quiescent current (under 100μA) to maintain tight control over output voltage and current, ensuring consistent power delivery to automation components.

Designing power supplies with these principles not only cuts energy waste but also reduces the need for bulky cooling solutions, saving space in tight warehouse setups.

Optimizing PCB Layout for Minimizing Power Loss in Warehouse Systems

Power loss in warehouse automation systems often comes from resistance in traces, poor grounding, or inefficient component placement. A well-thought-out PCB layout for minimizing power loss in warehouse systems can make a significant difference in overall efficiency.

1. Short and Wide Traces: For high-power paths, keep traces as short and wide as possible. A trace width of 1mm can handle about 2A with a 1oz copper layer, but for higher currents, scale up accordingly to avoid voltage drops and heat buildup.

2. Ground Planes: Use solid ground planes to provide a low-impedance return path for currents. This reduces noise and prevents power loss due to electromagnetic interference (EMI), which is common in busy warehouse environments with multiple electronic systems.

3. Component Placement: Place power components like regulators and capacitors close to the load to minimize trace length. For example, position decoupling capacitors within 5mm of IC power pins to stabilize voltage and reduce ripple.

These layout techniques ensure that power reaches critical components with minimal waste, supporting the high demands of warehouse automation systems.

Thermal Considerations for High-Power PCBs in Automation

Warehouse automation systems often operate under heavy loads, generating significant heat. Without proper management, this heat can degrade components or cause failures. Addressing thermal considerations for high-power PCBs is crucial for long-term reliability.

1. Heat Dissipation: Use thermal vias to transfer heat from hot components to a copper plane or heatsink on the opposite side of the PCB. For instance, placing 10-15 vias under a power IC can reduce junction temperature by 10-15°C.

2. Copper Pour Areas: Increase copper pour areas around high-power components to act as a heat spreader. A 2oz copper layer can handle more heat than a 1oz layer, improving thermal performance.

3. Component Spacing: Avoid crowding heat-generating components like power transistors or regulators. Maintain at least 3-5mm spacing to allow airflow and prevent localized hotspots.

Effective thermal design keeps systems running at safe temperatures, even during peak warehouse activity, preventing costly downtime due to overheating.

Choosing the Right PCB Materials for Efficient Energy Transfer in Warehouse Automation

The choice of materials in PCB manufacturing directly impacts energy efficiency and performance. Selecting the right PCB materials for efficient energy transfer in warehouse automation ensures minimal losses and maximum durability.

1. Substrate Materials: Standard FR-4 material works for many applications with a dielectric constant of about 4.5, but for high-frequency power supplies in automation, consider low-loss materials like Rogers with a dielectric constant closer to 3.0 to reduce signal loss.

2. Copper Thickness: Thicker copper layers (2oz or 3oz) are ideal for high-current applications like AGV charging systems, as they lower resistance and improve energy transfer. For example, a 2oz copper trace has roughly half the resistance of a 1oz trace for the same width.

3. Thermal Conductivity: For high-power designs, use substrates with higher thermal conductivity (above 1 W/mK) to better dissipate heat. Some advanced materials can offer up to 3 W/mK, significantly improving thermal management.

Matching the right materials to the specific needs of warehouse automation systems ensures efficient power delivery and long-term reliability under demanding conditions.

Best Practices for Designing Energy-Efficient PCBs for Warehouse Automation

Beyond the specific areas discussed, there are general best practices that tie everything together for creating energy-efficient PCBs in warehouse automation:

- Simulation and Testing: Use simulation tools to model power distribution and thermal performance before manufacturing. This can catch issues like voltage drops or hotspots early, saving redesign costs.

- Modular Design: Create modular PCBs where possible, allowing easy replacement or upgrades of power or charging circuits without redesigning the entire board.

- Compliance with Standards: Follow industry standards like IPC-2221 for trace spacing and current handling to ensure safety and performance in high-power applications.

Applying these practices ensures that your PCB designs not only meet current needs but are also adaptable to future advancements in warehouse automation technology.

The Future of PCB Design in Warehouse Automation

As warehouse automation continues to grow, the demand for smarter, more efficient energy systems will only increase. Advances like AI-driven design tools are already helping engineers optimize PCB layouts for power efficiency, as noted in recent industry discussions. Additionally, the push for sustainability means that energy-efficient designs will play a bigger role in reducing the carbon footprint of logistics operations.

By focusing on innovative PCB design now—whether through better layouts, advanced materials, or thermal management—engineers can build systems that are ready for tomorrow’s challenges. The future of warehouse automation depends on reliable, efficient power, and PCBs are at the center of making that happen.

Conclusion: Building Smarter Warehouse Energy Systems with PCB Design

Efficient warehouse automation starts with smart PCB design. From PCB design for warehouse automated guided vehicle charging to high-efficiency PCB power supplies for automation, every detail matters. By optimizing layouts to minimize power loss, addressing thermal considerations for high-power PCBs, and choosing the right PCB materials for efficient energy transfer in warehouse automation, engineers can create systems that save energy, reduce costs, and improve reliability.

ALLPCB

ALLPCB