In the fast-evolving world of hospitality technology, designing user-friendly interfaces for hotel room control systems on printed circuit boards (PCBs) is essential. Hotel guests expect seamless, intuitive controls for lighting, temperature, curtains, and more, all at their fingertips. By focusing on touchscreen interface design, capacitive touch sensing, HMI development, graphical user interfaces, and intuitive controls, manufacturers can create systems that enhance guest experiences while ensuring reliability and efficiency. At ALLPCB, we understand the importance of blending cutting-edge technology with user-centric design to meet these demands.

This blog dives deep into the key principles and technical considerations for designing effective hotel room control interfaces on PCBs. Whether you're an engineer, designer, or hospitality tech provider, you'll find actionable insights to create systems that are both functional and delightful to use.

Why User-Friendly Interfaces Matter in Hotel Room Controls

In a hotel setting, guests come from diverse backgrounds and may not be familiar with complex technology. A poorly designed interface can lead to frustration, negative reviews, and decreased satisfaction. On the other hand, a well-designed system with intuitive controls can elevate the guest experience, making their stay more comfortable and memorable. For hotel management, user-friendly designs also reduce the need for staff assistance, saving time and resources.

Hotel room control systems often integrate multiple functions—lighting, HVAC, entertainment, and security—into a single interface. PCBs serve as the backbone of these systems, connecting sensors, displays, and microcontrollers. By prioritizing touchscreen interface design and HMI development, engineers can ensure that these systems are easy to navigate, even for first-time users.

Key Elements of Touchscreen Interface Design for Hotel Room Controls

Touchscreen interface design is at the heart of modern hotel room control systems. A well-designed touchscreen can simplify complex operations into a few taps or swipes. Here are the critical aspects to consider when designing these interfaces on PCBs:

1. Layout Simplicity and Clarity

The layout of a touchscreen interface should prioritize simplicity. Icons and buttons must be large enough to tap easily, with clear labels or universally recognized symbols (e.g., a light bulb for lighting). Avoid cluttering the screen with too many options at once. Instead, use a hierarchical menu structure where primary functions are immediately accessible, and secondary settings are nested in sub-menus.

For instance, a typical hotel room control interface might display main functions like "Lights," "Thermostat," and "Curtains" on the home screen. Tapping "Lights" could reveal options for different zones or dimming levels. This approach minimizes cognitive load for users, ensuring intuitive controls.

2. Responsive Feedback

Guests expect immediate feedback when they interact with a touchscreen. If a user taps a button to turn on the lights, the system should respond within milliseconds, ideally under 100ms, to confirm the action visually or audibly. On the PCB level, this requires optimizing signal processing speeds between the touchscreen input and the microcontroller. A typical response time can be achieved with a microcontroller operating at a clock speed of 48 MHz or higher, ensuring smooth operation.

3. Durability and Maintenance

Hotel room control systems are used frequently, so the touchscreen must withstand wear and tear. Opt for materials like tempered glass or high-quality plastic overlays for the display. On the PCB, ensure that connectors and traces are designed to handle repeated inputs without signal degradation, using impedance values around 50 ohms for stable data transmission.

Leveraging Capacitive Touch Sensing for Seamless Interaction

Capacitive touch sensing is a game-changer for hotel room control interfaces. Unlike resistive touchscreens, which require pressure, capacitive screens detect the electrical charge from a user's finger, offering a smoother and more responsive experience. This technology is ideal for creating sleek, modern interfaces that feel premium.

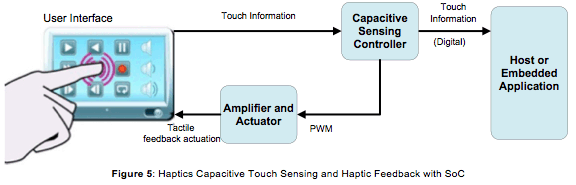

How Capacitive Touch Sensing Works

Capacitive touch sensing operates by detecting changes in an electric field when a conductive object, like a finger, comes near the screen. The PCB beneath the touchscreen includes a grid of electrodes that generate this field. When disrupted, the system calculates the touch location with high precision, often within 1mm accuracy.

For hotel room controls, this precision allows for smaller, closely spaced buttons without the risk of accidental inputs. Engineers must ensure the PCB design minimizes noise interference, which can be achieved by incorporating ground planes and keeping signal traces short, ideally under 10cm, to maintain signal integrity.

Benefits for Hotel Guests

Capacitive touchscreens support multi-touch gestures, like swiping or pinching, which can be used to adjust settings like brightness or temperature with a natural motion. They also work well in varying environmental conditions, such as humidity levels often found in hotel bathrooms, making them reliable across different room types.

HMI Development: Bridging Humans and Machines

HMI development, or Human-Machine Interface development, focuses on creating systems that allow seamless interaction between users and technology. In the context of hotel room control PCBs, HMI development involves integrating hardware and software to deliver a cohesive user experience.

Hardware Considerations

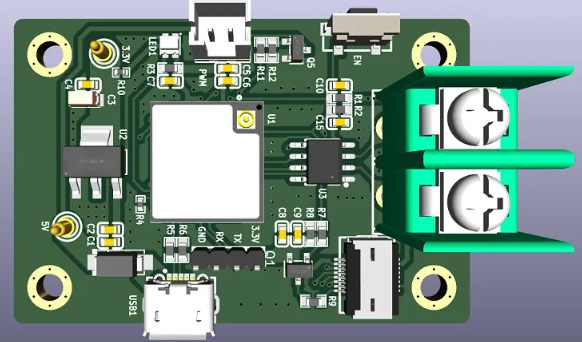

On the hardware side, the PCB must support the display, touch input, and connectivity to room systems like lighting or HVAC. A typical setup might include a 32-bit microcontroller with at least 256KB of flash memory to handle graphical rendering and touch input processing. The PCB layout should prioritize short, direct traces to reduce latency, with power supply lines designed to handle currents up to 500mA for stable operation.

Software Integration

Software plays a critical role in HMI development. The interface must be programmed to respond quickly and predictably to user inputs. For example, a guest adjusting the thermostat from 20°C to 22°C should see the change reflected instantly on the screen. Using real-time operating systems (RTOS) can help achieve response times under 50ms, ensuring smooth performance.

Additionally, the software should include error handling to prevent system crashes if a user inputs an invalid command. For instance, if a guest tries to set the temperature beyond the allowed range, the system should display a clear message like "Temperature limit reached" instead of freezing.

Creating Graphical User Interfaces for Maximum Appeal

Graphical user interfaces (GUIs) are the visual bridge between guests and hotel room control systems. A well-designed GUI can make even the most complex systems feel simple and approachable.

Color and Contrast

Use high-contrast colors to ensure visibility in different lighting conditions. For example, a dark background with white or yellow text works well in dimly lit rooms. Avoid overly bright or clashing colors that can strain the eyes. A color contrast ratio of at least 4.5:1 is recommended for readability, based on accessibility standards.

Iconography and Typography

Icons should be instantly recognizable—think of a fan for air conditioning or a bed for "Do Not Disturb" mode. Typography should be clean and sans-serif, with font sizes of at least 16 pixels for main text and 24 pixels for headings to ensure legibility on smaller screens, such as a 4-inch display commonly used in room controls.

Customization for Branding

Hotels often want interfaces that reflect their branding. GUIs can incorporate custom themes, logos, or welcome messages. On the PCB side, ensure the display driver supports high-resolution graphics, such as 800x480 pixels, to render these elements sharply without overloading the system memory.

Ensuring Intuitive Controls for All Users

The ultimate goal of designing hotel room control interfaces is to achieve intuitive controls that require no learning curve. Here are some strategies to ensure accessibility and ease of use:

Universal Design Principles

Design for a wide range of users, including those with limited tech experience or disabilities. Incorporate features like voice feedback or haptic responses (vibrations) to confirm actions. On the PCB, this might involve integrating a small piezo buzzer or vibration motor, requiring minimal current draws of around 20mA.

Testing and Iteration

Conduct user testing with diverse groups to identify pain points. For example, if testers struggle to locate the "Lights Off" button, consider increasing its size or moving it to a more prominent spot. Iterating based on feedback ensures the final design truly meets user needs.

Minimalist Approach

Avoid overwhelming users with too many features on a single screen. Focus on core functions that guests use most often, like adjusting temperature or controlling lights. Secondary features, like setting a wake-up alarm, can be tucked into a settings menu to keep the main interface clean.

Technical Challenges and Solutions in PCB Design for Hotel Interfaces

Designing PCBs for hotel room control systems comes with unique challenges. Here are some common issues and how to address them:

Power Management

Hotel room controls often run 24/7, so power efficiency is critical. Use low-power components, such as microcontrollers with sleep modes that reduce consumption to under 1mA when idle. Incorporate voltage regulators on the PCB to maintain stable power delivery, typically at 3.3V or 5V, to prevent glitches in the interface.

Signal Interference

With multiple systems running in a hotel room, electromagnetic interference (EMI) can disrupt touchscreen performance. Design the PCB with proper shielding, such as copper ground planes, and keep high-frequency traces away from sensitive touch sensor lines. Aim for a signal-to-noise ratio (SNR) of at least 40 dB for reliable touch detection.

Scalability

Hotels may want to upgrade or expand their systems over time. Design PCBs with modular connectors or extra GPIO pins on the microcontroller to allow for future additions, such as integrating smart locks or IoT features. A 40-pin microcontroller offers ample flexibility for such expansions.

Conclusion: Elevating Guest Experiences with Smart Design

Designing user-friendly interfaces for hotel room control PCBs is a blend of art and science. By focusing on touchscreen interface design, capacitive touch sensing, HMI development, graphical user interfaces, and intuitive controls, engineers can create systems that delight guests and streamline operations for hotel staff. At ALLPCB, we’re committed to supporting innovators in the hospitality sector with high-quality PCB manufacturing and assembly services tailored to these specialized needs.

From simplifying layouts to ensuring rapid response times, every detail matters in crafting interfaces that feel effortless to use. With the right approach, your hotel room control systems can transform a standard stay into an exceptional experience, setting new standards in hospitality technology.

ALLPCB

ALLPCB