When it comes to designing a printed circuit board (PCB) for embedded systems, one of the most critical decisions is choosing the right processor. Should you go with a Field-Programmable Gate Array (FPGA) or a Microcontroller (MCU)? Both have unique strengths and weaknesses, and the choice can significantly impact your project's performance, cost, and development timeline. In this comprehensive guide, we'll break down the differences between FPGA vs. microcontroller, helping you make an informed decision for your PCB processor selection. We'll dive into their features, applications, and key considerations for embedded systems design, ensuring you have the insights needed for your next project.

Quick Answer: FPGA or Microcontroller for Your PCB Design?

If you're looking for a quick recommendation, here's the gist: Choose the best microcontroller if your project requires low power consumption, cost-effectiveness, and simpler programming for tasks like sensor monitoring or basic control systems. Opt for an FPGA if you need high-speed processing, parallel task execution, or custom hardware configurations for complex applications like real-time signal processing or advanced imaging. Read on for a detailed comparison to understand which suits your specific needs in PCB design and embedded systems applications.

What Are Microcontrollers and FPGAs? A Basic Overview

Before diving into the comparison, let's clarify what each of these processors is and how they function in a PCB design context.

Microcontroller (MCU): The All-in-One Solution

A microcontroller is a compact integrated circuit that acts as a small computer on a single chip. It typically includes a central processing unit (CPU), memory (RAM and ROM), and input/output (I/O) peripherals. MCUs are designed for specific tasks and are widely used in embedded systems design due to their simplicity and efficiency. They execute instructions sequentially, making them ideal for applications where tasks are straightforward and predictable, such as controlling a motor or reading sensor data.

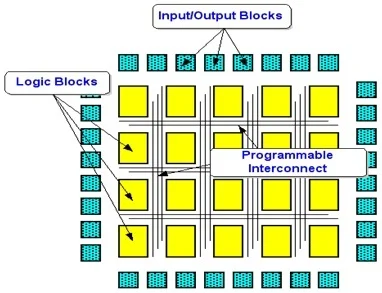

FPGA: The Customizable Powerhouse

An FPGA, or Field-Programmable Gate Array, is a highly configurable integrated circuit that allows designers to create custom hardware functionalities. Unlike MCUs, FPGAs don't have a fixed architecture; they consist of programmable logic blocks and interconnects that can be tailored to perform specific tasks. This makes them incredibly powerful for parallel processing and high-speed applications, such as digital signal processing or machine learning algorithms, often seen in the advanced PCB design.

FPGA vs. Microcontroller: Key Differences for PCB Design

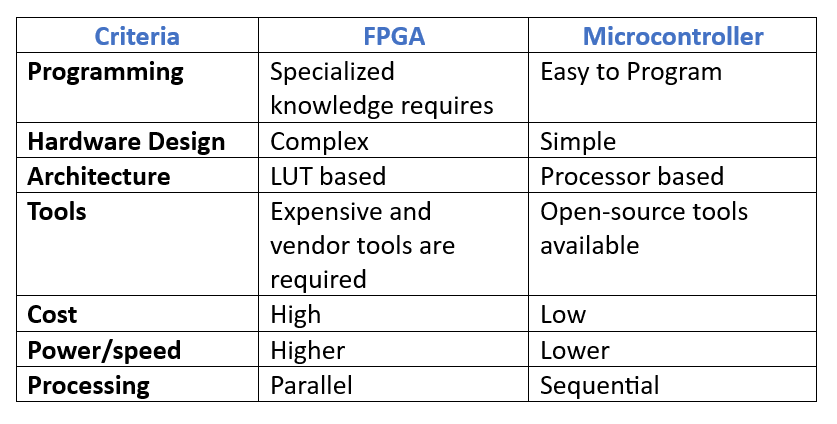

Understanding the differences between FPGAs and microcontrollers is essential for making the right choice in PCB processor selection. Let's compare them across several critical factors for embedded systems design.

1. Processing Power and Speed

Microcontroller: MCUs operate sequentially, meaning they process one instruction at a time. Their clock speeds typically range from a few MHz to a few hundred MHz (e.g., a popular 32-bit MCU might run at 80 MHz). This makes them suitable for applications where tasks are not time-critical, like controlling a home appliance.

FPGA: FPGAs excel in parallel processing, allowing multiple operations to occur simultaneously. They can achieve effective processing speeds equivalent to GHz ranges for specific tasks by leveraging custom hardware designs. For instance, in real-time signal processing, an FPGA can handle multiple data streams with minimal latency, making it ideal for high-speed PCB applications.

2. Flexibility and Customization

Microcontroller: MCUs have a fixed architecture, meaning their hardware capabilities are predefined. While you can program them using languages like C or Assembly, you can't alter their internal structure. This limits their flexibility for highly specialized tasks in embedded systems design.

FPGA: FPGAs offer unparalleled customization. You can program them at the hardware level using Hardware Description Languages (HDL) like VHDL or Verilog to create tailored logic circuits. This makes them perfect for unique or evolving project requirements, such as implementing a custom communication protocol on a PCB.

3. Power Consumption

Microcontroller: MCUs are generally power-efficient, especially in low-power modes. For example, many modern MCUs consume only a few microamps in sleep mode, making them ideal for battery-powered devices like wearable sensors or IoT gadgets.

FPGA: FPGAs typically consume more power due to their complex logic and higher operating frequencies. Their power draw can range from hundreds of milliwatts to several watts, depending on the design. This can be a drawback for portable or energy-constrained PCB designs.

4. Cost Considerations

Microcontroller: MCUs are cost-effective, with prices ranging from less than $1 for basic 8-bit models to around $10 for advanced 32-bit versions. They also require less complex PCB layouts, reducing overall design and manufacturing costs.

FPGA: FPGAs are more expensive, with costs starting at $10 for entry-level chips and going up to hundreds of dollars for high-end models. Additionally, their development requires specialized tools and expertise, increasing the upfront investment for PCB processor selection.

5. Development Time and Complexity

Microcontroller: Developing with an MCU is relatively straightforward. Programming is done in high-level languages, and many development environments offer extensive libraries and community support. A simple project, like a temperature monitoring system, can be prototyped in days.

FPGA: FPGA development is more complex and time-consuming. Designing custom hardware requires knowledge of HDL and simulation tools, and debugging can be challenging. A project leveraging FPGA applications in PCB design, such as a high-speed data acquisition system, might take weeks or months to complete.

Applications: When to Use FPGA vs. Microcontroller in PCB Design

The choice between FPGA and microcontroller often comes down to the specific requirements of your embedded systems design. Let's explore common use cases for each to guide your PCB processor selection.

Microcontroller Applications in PCB Design

MCUs are the go-to choice for projects where simplicity, low cost, and power efficiency are priorities. Here are some typical microcontroller applications in PCB design:

- IoT Devices: MCUs manage basic tasks like data collection and wireless communication in smart home devices. For example, a low-power MCU can read sensor data every few seconds and transmit it over a network with minimal energy use.

- Consumer Electronics: Products like remote controls or small appliances often use MCUs to handle user inputs and basic control functions.

- Automotive Systems: MCUs control non-critical systems like window motors or dashboard displays, where sequential processing is sufficient.

FPGA Applications in PCB Design

FPGAs shine in scenarios requiring high performance, parallel processing, or custom hardware solutions. Here are some common FPGA applications in PCB design:

- Digital Signal Processing (DSP): FPGAs are used in applications like audio or video processing, where they can handle multiple data streams simultaneously. For instance, an FPGA might process a 1080p video feed at 60 frames per second with custom filters.

- Telecommunications: FPGAs manage high-speed data protocols and encryption in networking equipment, ensuring low latency and high throughput.

- Machine Learning: In edge devices, FPGAs accelerate inference tasks by implementing custom neural network architectures directly in hardware.

Key Factors to Consider for PCB Processor Selection

Choosing between an FPGA and a microcontroller for your PCB design involves weighing multiple factors. Here are some critical considerations to guide your decision in embedded systems design:

1. Project Complexity and Performance Needs

If your project involves complex algorithms or real-time processing (e.g., image recognition with processing speeds requiring sub-millisecond latency), an FPGA is likely the better choice. For simpler tasks, like toggling LEDs based on a timer, an MCU will suffice.

2. Power and Size Constraints

For battery-operated or compact devices, prioritize an MCU due to its lower power consumption and smaller footprint. FPGAs, while powerful, often require more board space and additional power management components on the PCB.

3. Budget and Time-to-Market

If you're working with a tight budget or need a fast turnaround, MCUs are more economical and quicker to develop. FPGAs, while offering superior performance, come with higher costs and longer development cycles.

4. Scalability and Future-Proofing

FPGAs offer more scalability since you can reconfigure their hardware for new functionalities without changing the physical chip. This is useful for products that might need updates or feature expansions. MCUs, on the other hand, may require a complete redesign if requirements change.

Combining FPGA and Microcontroller in PCB Design

In some cases, you don't have to choose between FPGA and microcontroller—you can use both in a hybrid approach for embedded systems design. For example, an MCU can handle high-level control tasks and user interfaces, while an FPGA manages data-intensive or time-critical operations. This combination leverages the strengths of both processors, though it increases design complexity and cost.

A practical example is in industrial automation: an MCU might oversee the system's overall operation, communicating with sensors and actuators, while an FPGA processes high-speed encoder signals for precise motor control, achieving response times under 1 microsecond.

Tips for Successful PCB Processor Integration

Regardless of whether you choose an FPGA, microcontroller, or both, proper integration into your PCB design is crucial for performance and reliability. Here are some actionable tips:

- Optimize Power Delivery: Ensure stable power supply with appropriate decoupling capacitors near the processor pins. For FPGAs, consider multiple voltage rails (e.g., 1.2V for core, 3.3V for I/O) to avoid noise interference.

- Minimize Signal Integrity Issues: Keep high-speed traces short and match impedance (typically 50 ohms for digital signals) to prevent reflections, especially critical for FPGA designs operating at high frequencies.

- Use Proper Heat Management: FPGAs generate more heat than MCUs, so include thermal vias or heat sinks if necessary to maintain operating temperatures below 85°C for most chips.

- Leverage Development Tools: Use simulation software to test your design before fabrication, reducing errors in both MCU and FPGA implementations.

Conclusion: Making the Right Choice for Your PCB Design

Deciding between FPGA vs. microcontroller for your PCB processor selection ultimately depends on your project's specific needs in embedded systems design. If cost, simplicity, and low power are priorities, a microcontroller is often the best fit, excelling in applications like IoT and consumer electronics. If you require high-speed processing, parallel execution, or custom hardware solutions, an FPGA offers the flexibility and power needed for advanced tasks like digital signal processing or telecommunications.

By carefully evaluating factors like performance requirements, budget, and development timeline, you can choose the processor that aligns with your goals. Whether you're exploring microcontroller applications in PCB design or leveraging FPGA applications for cutting-edge solutions, a well-informed decision ensures your project succeeds. For expert guidance and high-quality PCB manufacturing services, trust our team to support your vision from concept to completion.

ALLPCB

ALLPCB