Some Tips on PCB Design for Cheap Manufacturing

Published on 12/24/2018 2:13:39 PM

Description

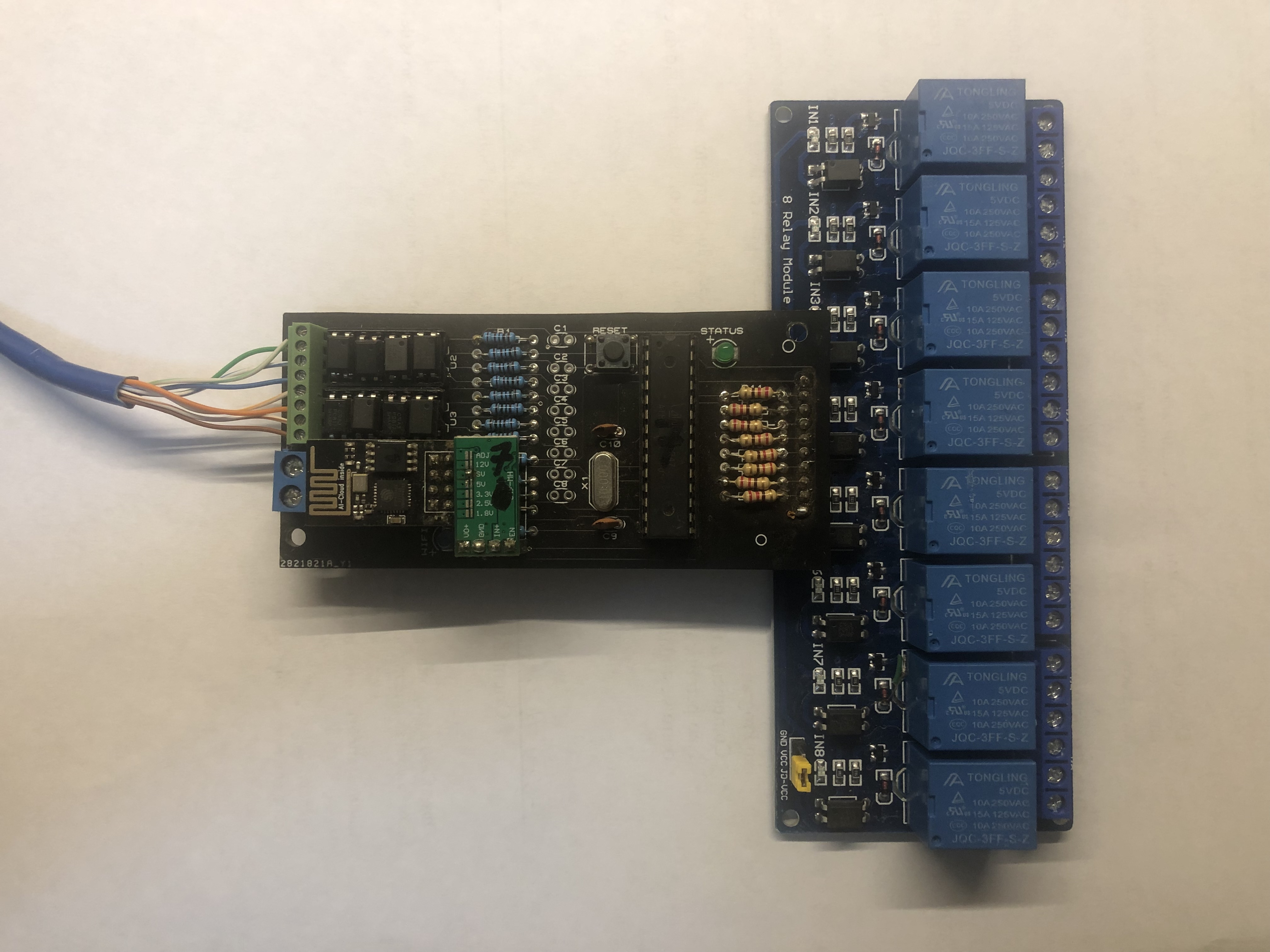

<p> <span style="font-family:"font-size:16px;">Design for Manufacturing and assembly are the integration of product design. The aim is to design a product that can be easily achieved and can be manufactured in a economic way. so there are some guidelines or tips which can be considered. </span> </p> <p> <span style="font-family:"font-size:16px;"></span> </p> <p> <span style="font-family:"font-size:16px;"><br /> </span> </p> <p> <span style="font-family:"font-size:16px;"><span style="font-family:"font-size:16px;">Especially for new designers, it is necessary and important to learn the guidelines to save cost for your first prototype </span><a href="https://www.allpcb.com/pcb_production" target="_blank"><span style="font-family:"font-size:16px;">PCB manufacturing</span></a><span style="font-family:"font-size:16px;">. </span></span> </p> <p> <br /> </p> <p style="text-align:center;"> <img src="https://file.allpcb.com/bbs/18/12/24/140332917.jpg" alt="designs for manufacturing" /> </p> <p style="text-align:center;"> <br /> </p> <span style="font-family:"font-size:16px;"><span style="font-family:"font-size:16px;">For any designs for manufacturing, the important </span><a href="https://www.allpcb.com/drilling_pcb_design.html" target="_blank"><span style="font-family:"font-size:16px;">design principles</span></a><span style="font-family:"font-size:16px;"> or rules is to help the designer or developer reduce their cost or reduce the difficulty of manufacturing of the pcb, and here below are a listing of these principles. The following are some suggestions or tips for designers to make a cost-effectively printed circuit boards. </span></span><br /> <br /> <span style="font-family:"font-size:16px;">As a matter of fact, about 60%-75% of manufacturing costs of the pcb or other products (quality of materials, production processing, and products assembly,ect.) are determined by design decisions.so it makes the designs so important for your projects in a cost effective way. </span><br /> <br /> <strong><span style="font-family:"font-size:16px;">1. Reduce Amount of Parts </span></strong><br /> <p> <br /> </p> <p> <span style="font-family:"font-size:16px;">Reduction of the amount of the parts or components is a good chances for reducing the manufacturing cost, less parts means less purchases,processing time, assembly difficulty, testing etc. It ease the processing process and in 90% it can reduce the assembly cost. In general, it reduces the level of intensity of all process related to the final finished product during its processing life. </span> </p> <br /> <strong><span style="font-family:"font-size:16px;">2. Use Standard Components</span></strong><br /> <p> <br /> </p> <p> <span style="font-family:"font-size:16px;"><span style="font-family:"font-size:16px;">The </span><strong><span style="font-family:"font-size:16px;">standard components</span></strong><span style="font-family:"font-size:16px;"> are normally in stock and easily sourced. resistors,capacitors in 0603,0204, which are easily purchased in many different channels.Standard components are less expensive than custom-made items due to the cost in delivery, customs etc in custom-made components. </span></span> </p> <p> <br /> </p> <p> <span style="font-family:"font-size:16px;">What’s more,the high availability of these components reduces product lead times. </span> </p> <span style="font-family:"font-size:16px;">As we all know,it will charge tax for the customized components or imported components, and some are forbidden in local market, absolutely it will cause extra cost to your final products. </span><br /> <br /> <div style="text-align:center;"> <img src="https://file.allpcb.com/bbs/18/12/24/140448706.jpg" alt="Use standard components" /> </div> <br /> <strong><span style="font-family:"font-size:16px;">3. Design for Ease Fabrication</span></strong><span style="font-family:"font-size:16px;"> </span><br /> <p> <span style="font-family:"font-size:16px;"><br /> </span> </p> <p> <span style="font-family:"font-size:16px;">Some designs are with special requirements, in very strange shape,with many slots or v cut lines, In general, excessive tolerance, surface-finish requirement, very small hole size, small track space, or heavy copper weight and so on are commonly found problems that result in higher than necessary production cost.</span> </p> <p> <span style="font-family:"font-size:16px;"><br /> </span> </p> <p> <span style="font-family:"font-size:16px;"><span style="font-family:"font-size:16px;">Select a good combination between material and design of fabrication process to minimize the overall </span><strong><span style="font-family:"font-size:16px;">manufacturing cost</span></strong><span style="font-family:"font-size:16px;">.</span></span> </p> <br /> <span style="font-family:"font-size:16px;">For example: </span><br /> <p> <br /> </p> <p> <span style="font-family:"font-size:16px;">Hole: normally 0.3mm is standard hole size, and hole below 0.3mm will lead to higher cost. Any buried vias, blind vias, half holes will also cause higher cost. </span> </p> <p> <br /> </p> <p> <span style="font-family:"font-size:16px;">Track space: standard is 6/6mil, 5/5mil or below will increase cost. </span> </p> <p> <br /> </p> <p> <span style="font-family:"font-size:16px;">Surface finish: HASL with lead is the cheapest, if make in immersion gold,take allpcb as example, it will have extra cost $22-$23. </span> </p> <p> <br /> </p> <p> <span style="font-family:"font-size:16px;"><a href="https://www.allpcb.com/soldermask/soldermask_color.html" target="_blank">Solder mask color</a>: green solder is most commonly used color for pcb, therefore it is the cheapest, and other color,like matt black,red, yellow will increase cost. </span> </p> <br /> <span style="font-family:"font-size:16px;">Hopefully above information are helpfully for those designers who are new and want to learn more about the cost-effective pcb manufacturing. </span><br /> <br />

59

comment

All comments

Unknown

Unknown

1006

0

59

Rules about cashback: 1. Valid time: ALLPCB cashback activity will end on April 1st. 2. Capped amount: The capped amount of cashback for each account is $5,000. Each order can get a maximum of $2,000 cashback. That means every author can get $5,000 max. 3. Cashback range: The cashback activity only covers the corresponding PCB order. The order amount for other combined payment products will be invalid. 4. Clicking your own promotional link will be invalid. The same email address, shipping address, contact information, and phone number are all recognized as the same account. 5. ALLPCB has the final interpretation right of the cashback activity.

ALLPCB will donate 2% to the author for this promotion link.