If you're searching for fast and affordable solutions for High-Tg PCB prototyping, you've come to the right place. High-Tg PCBs, known for their high glass transition temperature, are essential for applications requiring enhanced thermal stability and durability. At ALLPCB, we specialize in providing High-Tg PCB prototype services that combine speed, cost-effectiveness, and quality. Whether you're focused on High-Tg PCB quick turn options or managing High-Tg PCB prototype cost, we’ve got you covered with tailored solutions to meet your design and production needs.

In this comprehensive guide, we’ll dive deep into the world of High-Tg PCB prototyping. From understanding the benefits of High-Tg materials to exploring quick turn services, cost considerations, and design tips, this blog will equip you with actionable insights to streamline your next project.

What Are High-Tg PCBs and Why Do They Matter?

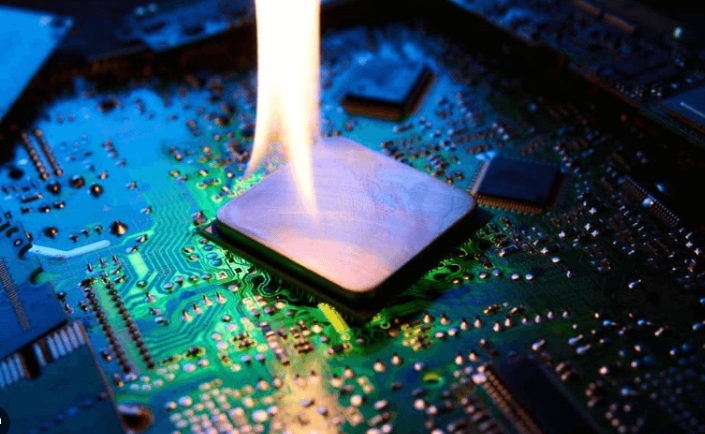

High-Tg PCBs are printed circuit boards made with materials that have a high glass transition temperature (Tg). The Tg is the temperature at which the PCB material transitions from a rigid state to a more flexible, rubbery state. Standard PCBs typically have a Tg of around 130°C to 140°C, while High-Tg PCBs offer a Tg of 170°C or higher, making them ideal for demanding environments.

These boards are critical in industries like automotive, aerospace, telecommunications, and industrial electronics, where components are exposed to high temperatures, vibrations, and harsh conditions. Using High-Tg materials ensures better thermal stability, reduced risk of delamination, and improved mechanical strength, all of which are vital for reliable performance.

For engineers working on High-Tg PCB prototype projects, choosing the right material can make or break the design. With the ability to withstand temperatures above 150°C without deforming, these boards support high-power components and multilayer designs, ensuring signal integrity even under stress.

Benefits of High-Tg PCB Prototyping for Your Projects

Prototyping with High-Tg materials offers several advantages, especially for engineers looking to test designs in challenging conditions. Here are the key benefits:

- Enhanced Thermal Resistance: High-Tg PCBs can handle operating temperatures up to 200°C or more, making them suitable for high-power applications like LED lighting or power supplies.

- Improved Durability: These boards resist cracking and delamination, ensuring longevity even under thermal cycling or mechanical stress.

- Better Signal Integrity: With a lower coefficient of thermal expansion (CTE), High-Tg materials maintain stable impedance values (typically around 50 ohms for high-speed signals), reducing signal loss in high-frequency applications.

- Support for Multilayer Designs: High-Tg PCBs are often used in complex, multilayer boards (up to 20 layers or more), which are common in advanced electronics.

For projects requiring a High-Tg PCB prototype, these benefits translate into fewer design iterations and faster time-to-market, as the prototype can more accurately reflect the performance of the final product.

High-Tg PCB Quick Turn Services: Speed Without Compromise

Time is often a critical factor in PCB development. Waiting weeks for a prototype can delay testing and production, costing valuable resources. That’s where High-Tg PCB quick turn services come in. At ALLPCB, we prioritize speed without sacrificing quality, ensuring you get your prototypes in as little as 24 to 48 hours for urgent projects.

Our streamlined manufacturing process is designed to handle High-Tg materials efficiently. Whether you need a single-layer board or a complex multilayer design, our advanced fabrication techniques and in-house testing ensure that your High-Tg PCB prototype meets exact specifications. We also offer expedited shipping options to get your boards to you as quickly as possible.

For engineers under tight deadlines, opting for High-Tg PCB quick turn services means you can test thermal performance, validate designs, and move to full production faster. Imagine submitting your design on Monday and having a fully functional prototype by Wednesday—our rapid turnaround makes this a reality.

High-Tg PCB Prototype Cost: Balancing Quality and Budget

One of the most common concerns for engineers is the High-Tg PCB prototype cost. While High-Tg materials are generally more expensive than standard FR-4 due to their specialized properties, there are ways to manage expenses without compromising on quality.

The cost of a High-Tg PCB prototype typically depends on several factors:

- Material Type: High-Tg laminates, such as Isola 370HR or Rogers RO4350B, cost more than standard materials but offer superior performance. Prices can range from $0.50 to $2.00 per square inch, depending on the specific material.

- Layer Count: Multilayer boards (e.g., 6 to 12 layers) increase costs due to added complexity. A 6-layer High-Tg PCB might start at $100 for a small batch, while a 12-layer design could exceed $300.

- Turnaround Time: Expedited High-Tg PCB quick turn services may add a premium of 20-50% to the base cost, but they save time in the long run.

- Quantity: Ordering multiple prototypes often reduces the per-unit cost. For example, a single prototype might cost $50, while ordering five could drop the price to $40 per board.

At ALLPCB, we provide transparent pricing and customizable options to keep your High-Tg PCB prototype cost within budget. By offering volume discounts and flexible turnaround times, we help you balance affordability with the need for high-quality prototypes.

High-Tg PCB Prototype Services: What to Expect

When choosing a provider for High-Tg PCB prototype services, it’s important to know what to expect. At ALLPCB, we offer a full range of services to support your project from concept to completion. Here’s what sets our High-Tg PCB prototype services apart:

- Material Expertise: We work with a variety of High-Tg laminates to match your thermal and electrical requirements, ensuring optimal performance for your application.

- Advanced Manufacturing: Our state-of-the-art facilities support tight tolerances (down to 3 mil trace width/spacing) and high-density interconnects (HDI) for complex designs.

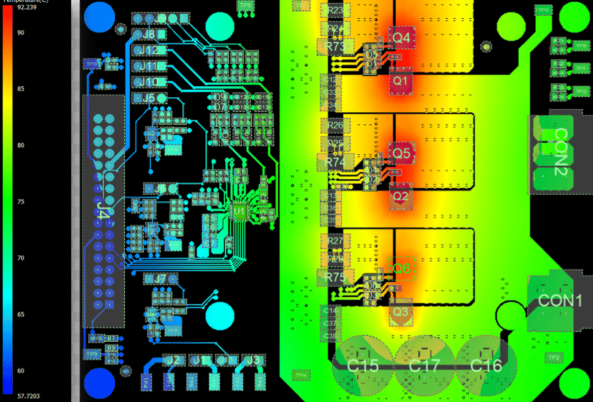

- Quality Assurance: Every High-Tg PCB prototype undergoes rigorous testing, including thermal stress tests and impedance control checks (targeting 50 ohms for high-speed signals), to ensure reliability.

- Customer Support: Our team of engineers is available to assist with design optimization, material selection, and troubleshooting at every stage.

Whether you’re developing a prototype for automotive electronics or high-frequency telecommunications equipment, our High-Tg PCB prototype services are tailored to deliver results that meet your exact needs.

High-Tg PCB Prototype Design: Tips for Success

Designing a High-Tg PCB prototype requires careful planning to ensure thermal stability and performance. Here are some practical tips to guide your High-Tg PCB prototype design process:

- Choose the Right Material: Select a High-Tg laminate with a Tg value that exceeds your application’s maximum operating temperature by at least 20°C. For example, if your device operates at 150°C, opt for a material with a Tg of 170°C or higher.

- Optimize Layer Stackup: For multilayer designs, balance copper thickness (typically 1 oz to 2 oz per layer) and dielectric layers to minimize thermal expansion and maintain signal integrity.

- Manage Thermal Dissipation: Incorporate thermal vias and heat sinks to dissipate heat from high-power components. Space vias at intervals of 0.3 to 0.5 inches for effective heat transfer.

- Control Impedance: High-Tg materials often have a stable dielectric constant (Dk) of around 3.5 to 4.5, which supports consistent impedance for high-speed signals (e.g., 50 ohms for differential pairs).

- Test Early and Often: Use simulation tools to predict thermal behavior and signal performance before fabrication. This reduces costly revisions during the High-Tg PCB prototype stage.

By following these High-Tg PCB prototype design tips, you can create a prototype that performs reliably under demanding conditions, saving time and resources in the long run.

Why Choose ALLPCB for High-Tg PCB Prototyping?

At ALLPCB, we understand the unique challenges of High-Tg PCB prototyping. Our commitment to fast, affordable, and high-quality solutions makes us a trusted partner for engineers worldwide. Here’s why you should choose us for your next High-Tg PCB prototype project:

- Speed: Our High-Tg PCB quick turn services ensure you receive prototypes in as little as 24 hours, keeping your project on track.

- Affordability: We offer competitive pricing and volume discounts to manage High-Tg PCB prototype cost effectively.

- Quality: With rigorous testing and advanced manufacturing, every High-Tg PCB prototype meets the highest industry standards.

- Customization: From material selection to layer stackup, our High-Tg PCB prototype services are tailored to your specific needs.

Our goal is to help you bring innovative designs to life with minimal hassle. Whether you’re working on a small batch of prototypes or preparing for full-scale production, we’re here to support you every step of the way.

Common Applications of High-Tg PCBs

High-Tg PCBs are used in a wide range of industries due to their ability to withstand extreme conditions. Some common applications include:

- Automotive Electronics: Engine control units (ECUs) and sensors that operate near high-temperature components.

- Aerospace Systems: Avionics and satellite equipment exposed to thermal cycling in harsh environments.

- Industrial Equipment: Power supplies and control systems that require reliable performance under heavy loads.

- Telecommunications: High-frequency base stations and routers with strict impedance control (e.g., 50 ohms for RF signals).

For each of these applications, a High-Tg PCB prototype allows engineers to validate designs under real-world conditions before committing to large-scale production.

Conclusion: Streamline Your High-Tg PCB Prototyping Today

High-Tg PCB prototyping doesn’t have to be slow or expensive. With the right partner, you can access fast, affordable solutions that meet your project’s unique requirements. At ALLPCB, we’re dedicated to providing top-tier High-Tg PCB prototype services, from quick turn options to cost-effective designs. Whether you’re focused on High-Tg PCB quick turn timelines, managing High-Tg PCB prototype cost, or perfecting your High-Tg PCB prototype design, we have the expertise and resources to help.

Start your next project with confidence by leveraging our comprehensive High-Tg PCB prototype services. With fast turnaround times, transparent pricing, and a commitment to quality, we’re ready to bring your innovative ideas to life.

ALLPCB

ALLPCB