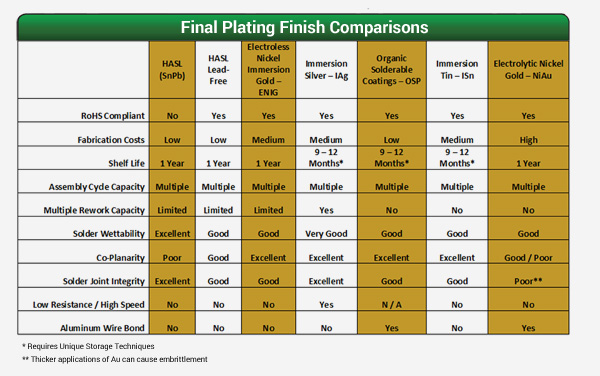

When it comes to designing drone flight control PCBs, selecting the right surface finish is critical for ensuring both protection and solderability. Drone electronics operate in demanding conditions, requiring durability, resistance to corrosion, and reliable soldering for components. So, which PCB surface finish is best for drones? The most common options include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), and Immersion Silver. Each has unique strengths and weaknesses, with factors like cost, environmental resistance, and soldering performance playing a role in the decision. In this comprehensive guide, we’ll dive deep into these surface finish options, helping you choose the right one for your drone flight control board based on protection needs and solderability requirements.

Why Surface Finish Matters for Drone Flight Control PCBs

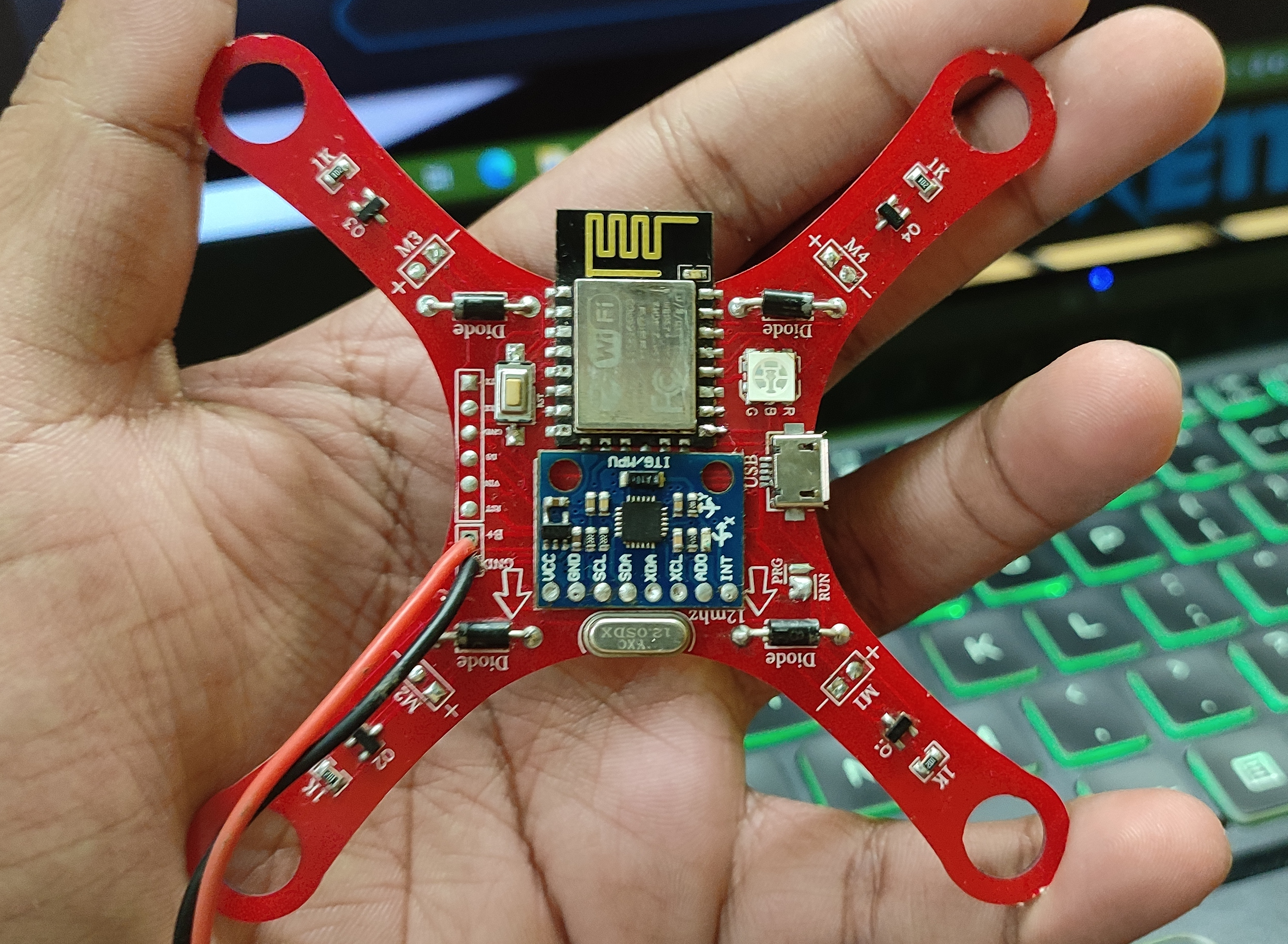

Drone flight control boards are the heart of unmanned aerial vehicles, managing navigation, stability, and communication. These PCBs are often exposed to harsh environments, including temperature fluctuations, humidity, and vibrations. A proper surface finish serves two primary purposes: protecting the copper traces from oxidation and ensuring a reliable surface for soldering components. Without the right finish, you risk signal degradation, component failure, or even complete board malfunction during flight.

The choice of surface finish directly impacts the PCB’s performance, longevity, and manufacturing cost. For instance, drone PCBs often require high-frequency signal transmission for real-time data processing, which can be affected by the finish’s electrical properties. Additionally, the finish must withstand multiple soldering cycles during assembly without degrading. Let’s explore how different finishes address these needs for drone applications.

Understanding PCB Surface Finish Options for Drones

Below, we’ll break down the four most relevant surface finish options for drone flight control PCBs, focusing on their benefits, drawbacks, and suitability for drone applications. These finishes are widely used in the industry and cater to different needs in terms of cost, durability, and performance.

1. HASL (Hot Air Solder Leveling)

HASL is one of the oldest and most cost-effective surface finishes available. In this process, the PCB is dipped in molten solder, and excess solder is blown off with hot air to create a flat, solderable surface. It’s a popular choice for many applications, but how does it hold up for drone flight control boards?

- Advantages:

- Cost-effective, making it ideal for budget-conscious projects.

- Excellent solderability due to the pre-applied solder layer, which supports strong component bonding.

- Can withstand multiple soldering cycles without significant degradation.

- Disadvantages:

- Uneven surface finish can cause issues with fine-pitch components often found on compact drone PCBs.

- Poor resistance to corrosion and oxidation over time, especially in humid or outdoor environments where drones operate.

- Not ideal for high-frequency applications due to potential signal interference from surface irregularities.

Suitability for Drones: HASL can work for prototype drone PCBs or low-cost consumer drones where environmental exposure is minimal. However, for professional or industrial drones that require reliability in tough conditions, other finishes may be better.

2. ENIG (Electroless Nickel Immersion Gold)

ENIG is a premium surface finish that involves applying a layer of nickel followed by a thin layer of gold over the copper traces. This finish is widely used in high-reliability applications, including aerospace and medical devices. For drone flight control PCBs, ENIG offers several compelling benefits.

- Advantages:

- Excellent corrosion resistance, protecting the PCB in harsh environments like high humidity or temperature extremes.

- Flat and uniform surface, ideal for fine-pitch components and high-density drone PCB designs.

- Superior electrical performance with minimal signal loss, supporting high-frequency signals (up to several GHz) for drone communication systems.

- Disadvantages:

- Higher cost compared to HASL, which may not be feasible for low-budget projects.

- Potential for "black pad" issues, a defect in the nickel layer that can affect solderability if not properly controlled during manufacturing.

Suitability for Drones: ENIG is an excellent choice for high-end drone flight control PCBs, especially for industrial or military drones where reliability and performance are paramount. Its ability to handle high-frequency signals and resist corrosion makes it a top pick for demanding applications.

3. OSP (Organic Solderability Preservative)

OSP is an eco-friendly surface finish that applies a thin organic coating to protect the copper from oxidation. It’s a lead-free option that has gained popularity for its simplicity and environmental benefits. But is it suitable for drone flight control boards?

- Advantages:

- Cost-effective and environmentally friendly, aligning with modern sustainability standards.

- Provides a flat surface for soldering, supporting fine-pitch components on compact drone PCBs.

- Good solderability for lead-free soldering processes, which are common in modern electronics.

- Disadvantages:

- Limited shelf life (typically 6-12 months) as the organic coating can degrade over time, making it less ideal for long-term storage.

- Less durable in harsh environments, with poor resistance to humidity and temperature extremes compared to ENIG.

- Not suitable for multiple soldering cycles, as the coating can break down after initial soldering.

Suitability for Drones: OSP can be a good choice for consumer-grade drones manufactured in high volumes with short production-to-use cycles. However, for drones exposed to challenging conditions or requiring long-term reliability, other finishes may offer better protection.

4. Immersion Silver

Immersion Silver involves depositing a thin layer of silver onto the copper traces through a chemical process. It’s a lead-free finish that offers a balance between cost and performance, making it a contender for drone PCB applications.

- Advantages:

- Excellent solderability, comparable to HASL, with strong bonding for components on drone flight control boards.

- Flat surface suitable for fine-pitch and high-density designs.

- Good electrical conductivity, supporting high-frequency signal transmission (up to 5 GHz or more depending on design).

- Disadvantages:

- Prone to tarnishing and oxidation over time, especially in high-humidity environments, which can affect solderability if not handled properly.

- Requires careful storage and handling to prevent surface degradation before assembly.

- Slightly higher cost than HASL or OSP, though more affordable than ENIG.

Suitability for Drones: Immersion Silver is a viable option for mid-range drone flight control PCBs where cost and performance need to be balanced. It works well for applications with controlled environmental exposure but may not be ideal for rugged outdoor drones.

Key Factors in Choosing a PCB Surface Finish for Drones

Selecting the right surface finish for your drone flight control PCB depends on several factors. Here’s a breakdown of the most important considerations to guide your decision.

1. Environmental Conditions

Drones often operate in diverse and harsh environments. If your drone will be used outdoors in humid, salty, or extreme temperature conditions, prioritize a finish with high corrosion resistance like ENIG. For indoor or controlled environments, more cost-effective options like HASL or OSP may suffice.

2. Solderability and Assembly Requirements

Drone PCBs often feature small, densely packed components that require precise soldering. Finishes like ENIG and Immersion Silver provide flat surfaces ideal for fine-pitch soldering, while HASL may pose challenges due to unevenness. Additionally, consider whether your assembly process involves multiple soldering cycles—ENIG and HASL are more durable in this regard compared to OSP.

3. Signal Integrity for High-Frequency Applications

Flight control boards often handle high-frequency signals for GPS, radio communication, and sensor data. Surface finishes like ENIG and Immersion Silver offer better electrical performance with minimal signal loss, making them suitable for drones requiring fast and reliable data transmission. For example, ENIG can support signal frequencies up to 10 GHz in well-designed boards, ensuring clear communication in real-time.

4. Cost Constraints

Budget is always a factor in PCB design. HASL and OSP are the most affordable options, suitable for low-cost consumer drones or prototypes. If you’re designing a high-performance drone and cost isn’t a primary concern, ENIG provides top-tier protection and performance despite its higher price point.

How Surface Finish Impacts PCB Solderability for Drones

Solderability is a critical aspect of any PCB finish, especially for drone flight control boards where component reliability can mean the difference between a successful flight and a crash. Solderability refers to how well solder adheres to the PCB surface, forming strong and lasting connections with components.

Finishes like HASL and Immersion Silver are known for excellent solderability due to their metallic coatings, which naturally bond with solder. ENIG also offers good solderability, though it requires precise manufacturing to avoid issues like black pad defects. OSP, while initially providing good solderability, can degrade over time or after multiple soldering attempts, making it less reliable for complex assembly processes.

For drone PCBs, poor solderability can lead to weak joints, increasing the risk of component failure under vibration or thermal stress during flight. Therefore, choosing a finish with consistent solderability is essential, especially for critical components like microcontrollers and sensors.

Comparing Protection Levels of Surface Finishes for Drone PCBs

Protection against oxidation and environmental damage is another key consideration for drone flight control boards. Here’s how the finishes stack up:

- ENIG: Offers the best protection with its nickel and gold layers, resisting corrosion even in high-humidity conditions (up to 85% relative humidity as per industry testing standards).

- Immersion Silver: Provides moderate protection but is prone to tarnishing if exposed to air or sulfur-containing environments for extended periods.

- HASL: Has limited corrosion resistance, with the solder layer degrading over time, especially in outdoor settings.

- OSP: Offers minimal long-term protection, as the organic coating can wear off, leaving copper vulnerable to oxidation after 6-12 months.

For drones used in rugged or outdoor applications, prioritizing a finish with strong protective qualities like ENIG can extend the lifespan of the PCB and ensure consistent performance.

Practical Tips for Selecting the Right PCB Surface Finish for Drones

To make an informed decision, follow these practical steps when choosing a surface finish for your drone flight control PCB:

- Evaluate the operating environment of your drone. Will it face extreme weather, humidity, or dust? If so, lean toward ENIG for maximum protection.

- Consider the complexity of your PCB design. If it includes fine-pitch components or high-density layouts, avoid HASL and opt for ENIG or Immersion Silver.

- Assess your budget. For low-cost drones or prototypes, HASL or OSP can save on expenses without sacrificing basic functionality.

- Think about signal requirements. If your drone relies on high-frequency communication, prioritize finishes like ENIG that minimize signal loss.

- Plan for storage and assembly timelines. If your PCBs will be stored for long periods before assembly, avoid OSP due to its limited shelf life.

Conclusion: Making the Best Choice for Drone Flight Control PCBs

Choosing the right PCB surface finish for drones is a balancing act between protection, solderability, performance, and cost. HASL offers affordability and decent solderability but lacks in environmental resistance. ENIG stands out for its superior protection and signal integrity, making it ideal for high-performance drones despite its higher cost. OSP is an eco-friendly, budget-friendly option for short-term or controlled use, while Immersion Silver provides a middle ground with good solderability and moderate protection.

Ultimately, the best surface finish depends on your specific drone application. For industrial or military drones operating in harsh conditions, investing in ENIG can ensure reliability. For consumer-grade or prototype drones, HASL or OSP may suffice. By carefully considering environmental factors, assembly needs, and signal requirements, you can select a finish that enhances the durability and performance of your drone flight control PCB.

ALLPCB

ALLPCB