If you're looking for ways to extend the life of your PCB stencil and ensure consistent performance in your printed circuit board assembly, you've come to the right place. Proper stencil care can save you time, reduce costs, and improve the quality of your PCB production. In this comprehensive guide, we'll share practical stencil care tips, PCB life tips, and PCB stencil prolong tips to help you extend stencil life and extend life stencil PCB. Let's dive into the details of maintaining your stencil for long-term success.

Why PCB Stencil Care Matters

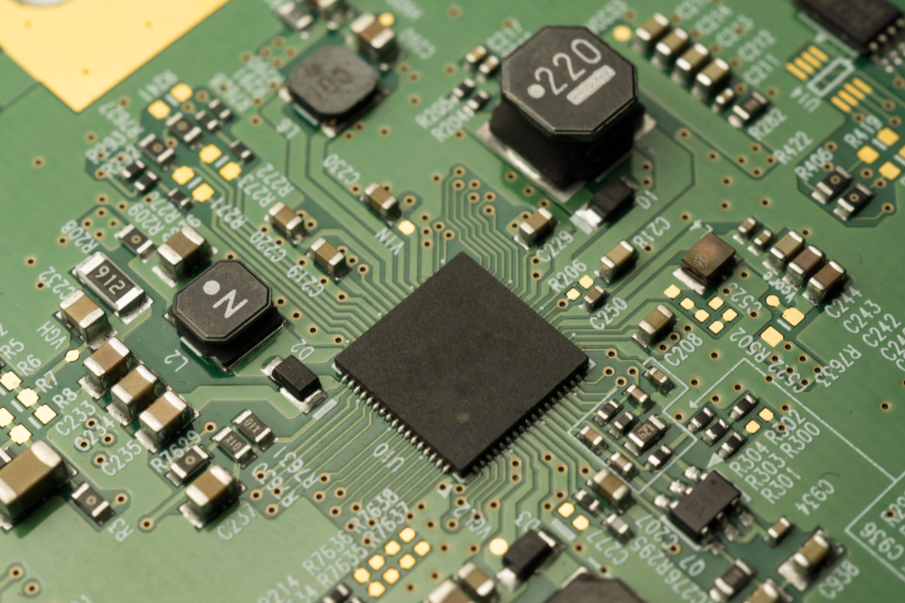

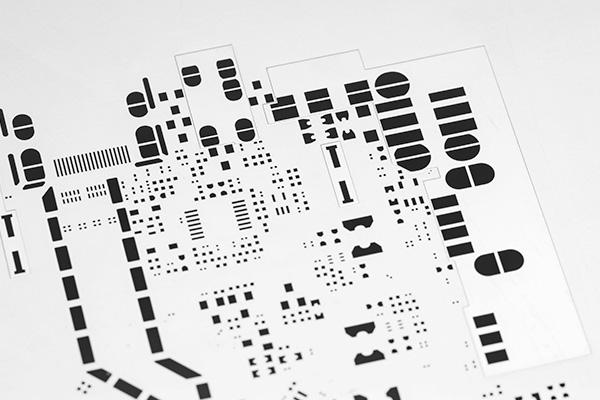

PCB stencils are critical tools in the surface-mount technology (SMT) process, ensuring precise solder paste application on printed circuit boards. These thin sheets, often made of stainless steel, have laser-cut openings that align with the PCB's pads. However, without proper care, stencils can wear out quickly, leading to inconsistent paste application, defects, and costly replacements. By following effective stencil care tips, you can prolong the lifespan of your stencil, reduce material waste, and maintain high-quality PCB assembly.

Understanding the Basics of PCB Stencils

Before diving into care tips, let's briefly cover what a PCB stencil is and why it’s so important. A stencil is a precision tool used to deposit solder paste onto specific areas of a PCB during assembly. The openings in the stencil correspond to the pads where components will be placed. Stencils are typically made from durable materials like stainless steel to withstand repeated use, often handling thousands of prints if maintained properly. Poor care, however, can lead to issues like clogged apertures, uneven paste deposits, or physical damage, all of which reduce the stencil's effectiveness.

Top PCB Stencil Care Tips to Prolong Life

Now, let’s explore actionable PCB stencil prolong tips and PCB life tips to help you extend stencil life. These strategies are designed for engineers and technicians who want to maximize the value of their tools while maintaining high production standards.

1. Clean Your Stencil Regularly and Properly

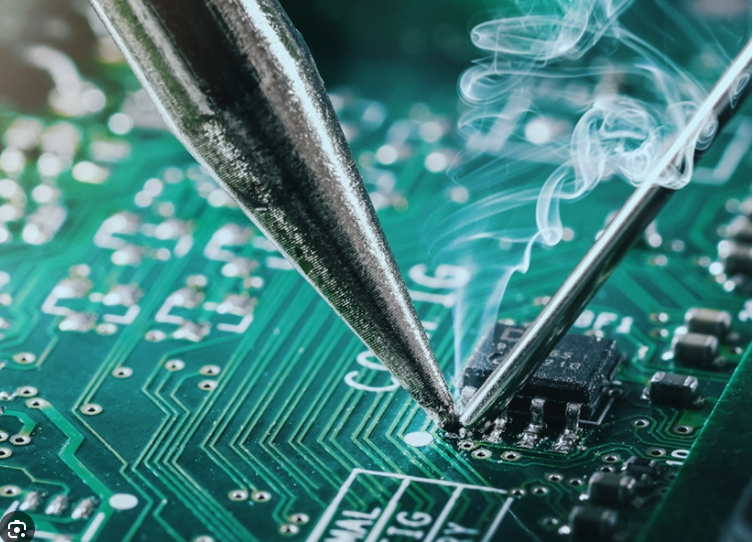

One of the most critical stencil care tips is regular cleaning. Solder paste residue can build up in the stencil’s apertures after each use, leading to blockages that cause uneven paste application. Over time, dried paste can harden, making it difficult to remove and potentially damaging the stencil during cleaning.

- Use the Right Cleaning Method: Employ an automated stencil cleaning machine with a suitable solvent, such as isopropyl alcohol or a specialized stencil cleaner. Manual cleaning with lint-free wipes can work for smaller operations but requires extra caution to avoid scratching the stencil.

- Clean After Every Use: Ideally, clean the stencil after every 5-10 prints or at the end of a production run to prevent paste from drying in the apertures.

- Dry Thoroughly: After cleaning, ensure the stencil is completely dry to avoid rust or corrosion, especially for stainless steel stencils.

Regular cleaning can significantly extend life stencil PCB by preventing long-term damage from residue buildup.

2. Handle Stencils with Care to Avoid Physical Damage

Physical damage is a common reason for stencil wear. Bending, scratching, or denting the stencil can distort the apertures, leading to inaccurate solder paste deposits. Follow these PCB life tips to handle your stencil properly:

- Use Protective Gloves: Always wear clean, lint-free gloves when handling stencils to avoid transferring oils or dirt from your hands onto the surface.

- Avoid Dropping or Bending: Handle the stencil gently and avoid placing heavy objects on top of it. Even a slight bend can misalign the apertures.

- Use Proper Tools: When aligning or mounting the stencil, use tools specifically designed for SMT processes to prevent accidental damage.

By treating your stencil with care, you can extend stencil life and avoid costly replacements due to preventable damage.

3. Store Stencils Correctly to Prevent Wear

Improper storage can lead to scratches, rust, or deformation, shortening the stencil’s lifespan. Incorporate these PCB stencil prolong tips into your storage routine:

- Store Flat or Vertically: Keep stencils flat in a protective case or hang them vertically in a dedicated rack to avoid bending.

- Use Protective Covers: Place a protective sheet or cover over the stencil to shield it from dust and accidental scratches.

- Control Environment: Store stencils in a clean, dry, and temperature-controlled area to prevent rust or corrosion. Aim for a humidity level below 50% to minimize moisture exposure.

Proper storage is a simple yet effective way to extend life stencil PCB and maintain its precision over time.

4. Inspect Stencils Regularly for Wear and Tear

Routine inspections are essential for catching issues early. Damaged or worn-out apertures can lead to poor solder paste transfer, resulting in defects like insufficient solder or bridging. Use these stencil care tips for effective inspection:

- Visual Checks: Use a magnifying glass or microscope to inspect the apertures for blockages, scratches, or deformations after every few uses.

- Measure Aperture Size: Over time, apertures can enlarge due to wear, affecting paste volume. Use precision tools to measure aperture dimensions and compare them to the original specifications (e.g., a typical aperture size for 0402 components might be 0.2 mm x 0.25 mm).

- Replace When Necessary: If you notice significant wear or damage that affects performance, consider replacing the stencil to avoid compromising PCB quality.

Regular inspections help you extend stencil life by addressing small issues before they become major problems.

5. Use the Correct Solder Paste and Printing Parameters

The type of solder paste and printing settings you use can impact stencil longevity. Incorrect parameters can cause excessive wear or residue buildup. Keep these PCB life tips in mind:

- Choose Compatible Solder Paste: Use a paste with a viscosity and particle size suitable for your stencil’s aperture dimensions. For fine-pitch components, Type 4 or Type 5 paste (particle size 15-25 μm or 10-18 μm) is often recommended for better release through small openings.

- Optimize Printing Pressure: Excessive squeegee pressure can wear down the stencil or damage apertures. Adjust the pressure to a moderate level (e.g., 3-5 kg for standard stencils) to ensure clean paste transfer without strain.

- Control Printing Speed: A slower printing speed (e.g., 20-50 mm/s) can reduce wear on the stencil while ensuring even paste distribution.

Using the right materials and settings is a key way to extend life stencil PCB and maintain consistent results.

Common Mistakes to Avoid in PCB Stencil Care

Even with the best intentions, certain mistakes can shorten your stencil’s lifespan. Here are some pitfalls to avoid when aiming to extend stencil life:

- Using Harsh Cleaning Chemicals: Aggressive solvents can corrode or weaken the stencil material. Stick to recommended cleaning agents.

- Neglecting Cleaning Schedules: Skipping cleaning sessions allows paste to harden, making it harder to remove and increasing the risk of damage.

- Improper Alignment: Misaligning the stencil during printing can cause uneven wear or physical stress on specific areas.

By avoiding these errors, you can follow effective PCB stencil prolong tips and keep your stencil in top condition.

Benefits of Prolonging PCB Stencil Life

Investing time in stencil care tips offers several advantages for your PCB assembly process:

- Cost Savings: A well-maintained stencil can last for tens of thousands of prints, reducing the need for frequent replacements. For example, replacing a stencil can cost anywhere from $100 to $500 depending on size and complexity.

- Improved Quality: Consistent stencil performance ensures accurate solder paste application, reducing defects like solder bridges or insufficient paste.

- Reduced Downtime: Proper care minimizes the need for emergency replacements or repairs, keeping your production line running smoothly.

These benefits highlight why it’s worth the effort to extend life stencil PCB through diligent maintenance.

Conclusion: Take Action to Extend Stencil Life

Caring for your PCB stencil is a straightforward but impactful way to improve your assembly process and save on costs. By following the PCB stencil prolong tips and stencil care tips outlined in this guide—such as regular cleaning, careful handling, proper storage, routine inspections, and optimized printing parameters—you can significantly extend stencil life. These PCB life tips ensure that your stencil remains a reliable tool for countless production runs.

Start implementing these strategies today to see the difference in your stencil’s performance and longevity. With a little attention and care, you can extend life stencil PCB and achieve consistent, high-quality results in every project.

ALLPCB

ALLPCB