In the fast-evolving world of railway electronics, ensuring reliable and efficient performance is critical. Heavy copper PCBs (Printed Circuit Boards) have emerged as a game-changer for railway signaling systems, offering unmatched durability and high current handling capabilities. If you're wondering how heavy copper PCBs can enhance railway signaling systems, the answer lies in their ability to manage high power distribution, withstand harsh environments, and ensure robust PCB design for critical applications. In this blog, we’ll dive deep into the specific advantages of heavy copper PCBs, exploring their role in power distribution, railway electronics, and more.

What Are Heavy Copper PCBs?

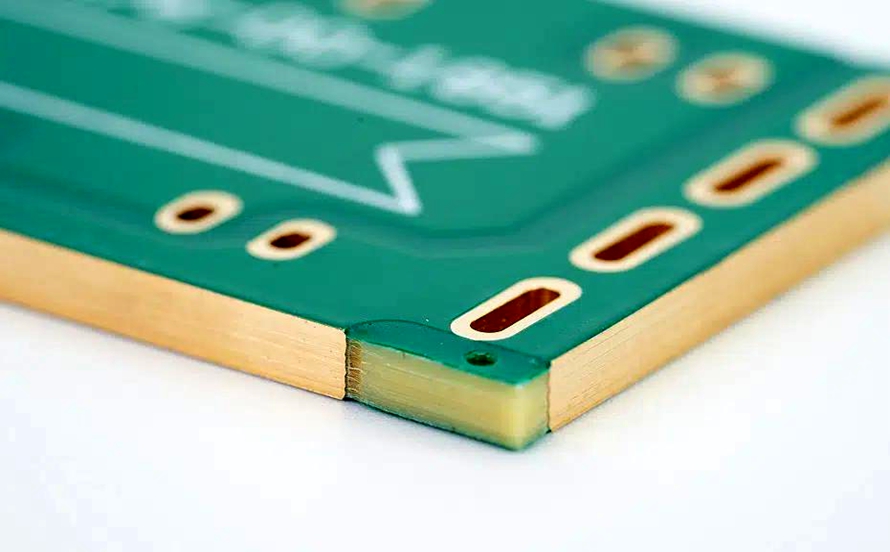

Heavy copper PCBs are specialized circuit boards designed with thicker copper layers compared to standard PCBs. While a typical PCB might have copper layers of 1-2 ounces per square foot, heavy copper PCBs can feature copper thicknesses of 3 ounces or more, sometimes reaching up to 20 ounces. This increased copper thickness allows these boards to handle higher currents, dissipate heat more effectively, and provide greater mechanical strength.

In railway signaling systems, where reliability and safety are non-negotiable, heavy copper PCBs play a vital role. They are built to endure the demanding conditions of railway environments, including extreme temperatures, vibrations, and electrical stress. Let’s explore why these boards are becoming the go-to choice for high current PCB applications in railway electronics.

Key Benefits of Heavy Copper PCBs in Railway Signaling Systems

Railway signaling systems are the backbone of safe and efficient train operations. They control train movements, prevent collisions, and ensure smooth communication across vast networks. Heavy copper PCBs bring several benefits to these systems, making them ideal for power distribution and robust PCB design. Below, we break down the specific advantages.

1. Superior High Current Handling for Power Distribution

Railway signaling systems often require high current PCB solutions to manage the power needed for signal lights, control units, and communication devices. Heavy copper PCBs excel in this area by supporting currents far beyond the capacity of standard boards. For instance, while a typical PCB might handle currents up to 5-10 amps, heavy copper boards can manage 20-100 amps or more, depending on the copper thickness and design.

This capability is crucial for power distribution in railway electronics, where consistent and reliable energy flow is essential. With heavy copper PCBs, the risk of overheating or circuit failure due to high current loads is significantly reduced, ensuring uninterrupted operation of signaling systems.

2. Enhanced Heat Dissipation for Reliability

Heat management is a major concern in railway electronics, especially in outdoor signaling equipment exposed to varying temperatures. Heavy copper PCBs are designed to dissipate heat more effectively than standard boards due to their thicker copper layers. This reduces the thermal stress on components and prevents damage to critical circuits.

For example, in a railway signaling control unit, the power supply module might generate significant heat during operation. A heavy copper PCB can spread this heat across a larger surface area, maintaining optimal operating temperatures and extending the lifespan of the system. This makes them a reliable choice for robust PCB design in harsh environments.

3. Increased Mechanical Strength for Harsh Environments

Railway signaling systems are often installed in challenging locations, such as along tracks or in remote areas, where they are exposed to vibrations, shocks, and environmental wear. Heavy copper PCBs offer greater mechanical strength compared to standard boards, thanks to their thicker copper layers and reinforced construction.

This durability ensures that the PCBs can withstand the constant vibrations from passing trains or the physical stress of installation in rugged terrains. A robust PCB design using heavy copper minimizes the risk of cracks or delamination, which could lead to system failures and costly downtime in railway operations.

4. Improved Signal Integrity in Railway Electronics

Signal integrity is paramount in railway signaling systems, where even a small glitch can have serious consequences. Heavy copper PCBs contribute to better signal integrity by reducing impedance and minimizing electrical noise. The thicker copper layers provide a stable path for electrical signals, ensuring clear communication between components.

For instance, in a railway signaling system, the control board must transmit data at high speeds with minimal interference. Heavy copper PCBs can maintain low impedance values—often in the range of 50-75 ohms for high-frequency signals—ensuring accurate and reliable data transfer. This is a key advantage for modern railway electronics that rely on precise timing and coordination.

5. Long-Term Cost Efficiency

While heavy copper PCBs may have a higher upfront cost compared to standard boards, they offer significant long-term savings for railway signaling systems. Their ability to handle high currents, resist thermal stress, and endure harsh conditions reduces the need for frequent replacements or repairs. This durability translates to lower maintenance costs and less downtime, which is critical for railway operators managing large-scale networks.

Additionally, the robust PCB design of heavy copper boards means fewer failures in the field, reducing the risk of delays or safety incidents caused by malfunctioning signaling equipment. Investing in high-quality heavy copper PCBs is a smart choice for railway projects focused on sustainability and efficiency.

Applications of Heavy Copper PCBs in Railway Signaling Systems

Heavy copper PCBs are versatile and can be used in various components of railway signaling systems. Their unique properties make them suitable for both power distribution and control applications. Here are some specific use cases where heavy copper PCBs shine in railway electronics.

Power Supply Units for Signaling Equipment

Power supply units in railway signaling systems need to deliver stable and high current outputs to drive signal lights, relays, and other devices. Heavy copper PCBs are ideal for these units because they can handle the electrical load without overheating or degrading over time. Their design ensures consistent power distribution, even under fluctuating voltage conditions common in railway environments.

Control and Communication Boards

Modern railway signaling systems rely on advanced control and communication boards to manage train movements and transmit real-time data. Heavy copper PCBs provide the necessary electrical stability and signal integrity for these boards, ensuring accurate operation. Whether it’s a trackside controller or a central monitoring system, heavy copper PCBs help maintain seamless connectivity across the network.

Traction and Power Converters

In railway systems, traction converters and power converters are used to manage the energy supply for trains and signaling equipment. These converters often deal with high currents and voltages, making heavy copper PCBs a perfect fit. Their ability to handle electrical stress and dissipate heat ensures the converters operate efficiently, contributing to the overall safety and performance of the railway network.

Design Considerations for Heavy Copper PCBs in Railway Signaling

While heavy copper PCBs offer numerous benefits, designing them for railway signaling systems requires careful planning to maximize their advantages. Below are some key considerations for engineers working on high current PCB projects.

Copper Thickness and Layer Configuration

The copper thickness of a heavy copper PCB should be chosen based on the current requirements of the signaling system. For example, a system handling 50 amps may require copper layers of 6-8 ounces per square foot, while higher loads might need 10 ounces or more. Additionally, multi-layer configurations can be used to separate power and signal paths, reducing interference and improving performance.

Thermal Management Features

To enhance heat dissipation, designers can incorporate thermal vias and heat sinks into heavy copper PCBs. Thermal vias help transfer heat away from critical components, while heat sinks provide additional surface area for cooling. These features are especially important for outdoor railway signaling equipment exposed to high ambient temperatures.

Compliance with Industry Standards

Railway signaling systems must adhere to strict industry standards for safety and reliability. Heavy copper PCBs should be designed and manufactured to meet relevant certifications, such as those related to environmental durability and electrical performance. Ensuring compliance helps guarantee that the PCBs will perform reliably in real-world railway conditions.

Why Choose Heavy Copper PCBs for Your Railway Projects?

The railway industry demands solutions that prioritize safety, efficiency, and longevity. Heavy copper PCBs meet these needs by offering superior high current handling, excellent heat dissipation, and unmatched durability. Whether you’re working on power distribution for signal lights or designing control boards for communication systems, heavy copper PCBs provide the robust PCB design necessary for success.

At ALLPCB, we specialize in delivering high-quality heavy copper PCBs tailored to the unique requirements of railway electronics. Our expertise in manufacturing and assembly ensures that your signaling systems operate with precision and reliability, even in the most demanding environments.

Conclusion

Heavy copper PCBs are transforming the landscape of railway signaling systems by providing the strength and performance needed for high current PCB applications. From improved power distribution to enhanced signal integrity, these boards offer a range of benefits that make them indispensable in railway electronics. Their robust PCB design ensures they can withstand the rigors of railway environments, delivering long-term reliability and cost efficiency.

As the railway industry continues to advance, adopting heavy copper PCBs is a forward-thinking choice for engineers and project managers. By leveraging their unique capabilities, you can build signaling systems that are safer, more efficient, and built to last. Explore the possibilities of heavy copper PCBs with ALLPCB and take your railway projects to the next level.