When it comes to HVAC control panel PCB assembly, choosing the right technology is crucial for performance, cost, and reliability. The two primary methods—Surface Mount Technology (SMT) and Through-Hole Technology (THT)—each have unique strengths and weaknesses. For HVAC PCB SMT assembly, you get compact designs and faster production, while HVAC PCB through-hole offers durability for high-power components. In this detailed guide, we’ll break down these PCB assembly methods to help you decide which is best for your HVAC control panel needs.

Whether you’re an engineer designing control systems for heating, ventilation, and air conditioning units or a manufacturer looking to optimize production, understanding these technologies is essential. Let’s dive into the specifics of SMT and THT, compare their applications in HVAC systems, and explore how they impact design, cost, and performance.

What Are HVAC Control Panel PCBs?

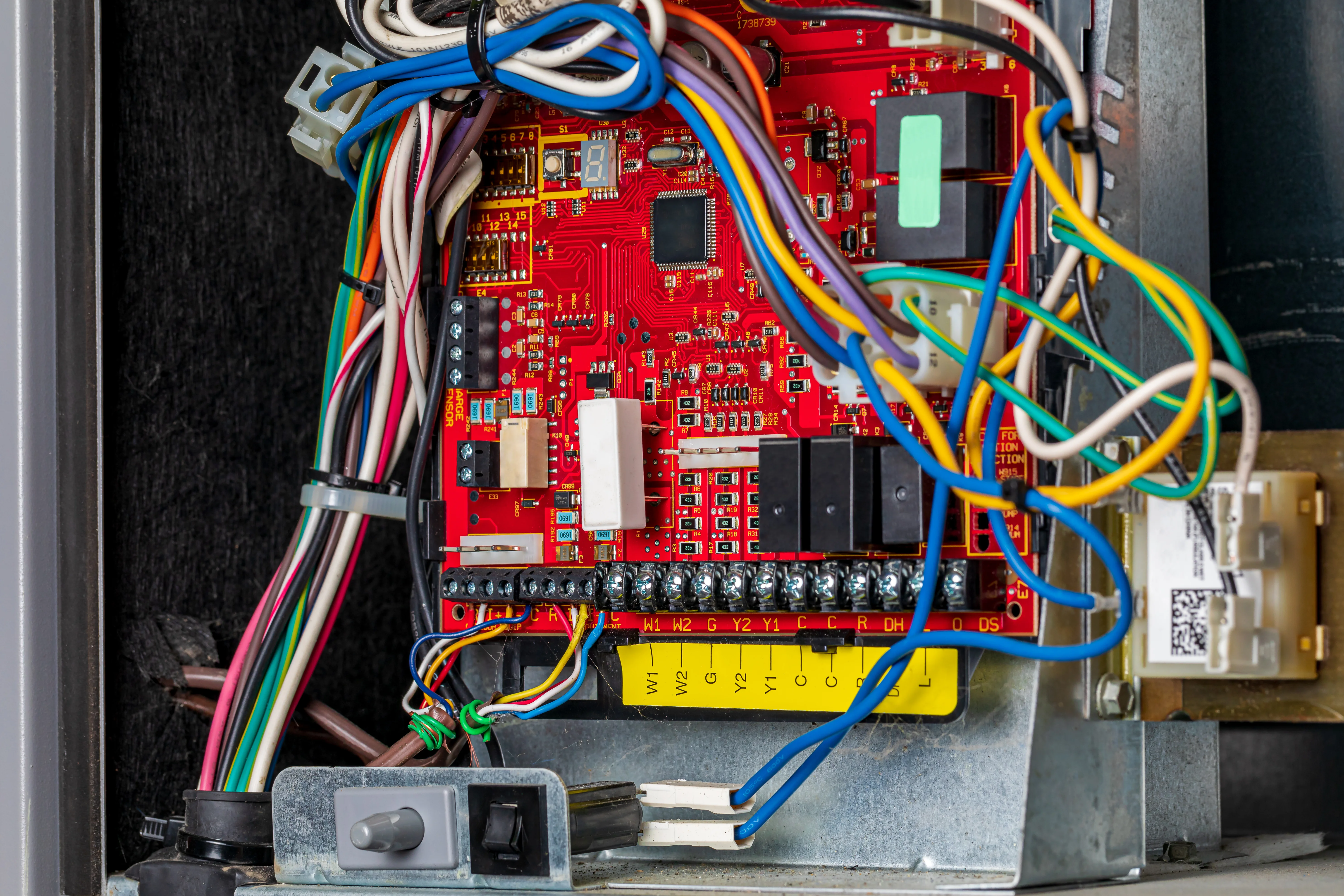

HVAC control panel PCBs (Printed Circuit Boards) are the brains behind modern heating, ventilation, and air conditioning systems. These boards manage critical functions like temperature regulation, fan speed control, and energy efficiency. They integrate sensors, microcontrollers, and power components to ensure seamless operation in residential, commercial, or industrial settings.

In HVAC systems, PCBs must withstand temperature fluctuations, vibrations, and sometimes high power demands. This makes the choice of assembly method—whether HVAC PCB SMT assembly or HVAC PCB through-hole—a key factor in ensuring reliability and longevity. Let’s explore the two main PCB assembly methods and how they apply to HVAC control panels.

Understanding PCB Assembly Methods: SMT and Through-Hole

PCB assembly involves attaching electronic components to a board to create a functional circuit. The two dominant methods are Surface Mount Technology (SMT) and Through-Hole Technology (THT). Each method has distinct processes and characteristics that influence their suitability for HVAC applications.

What Is Surface Mount Technology (SMT)?

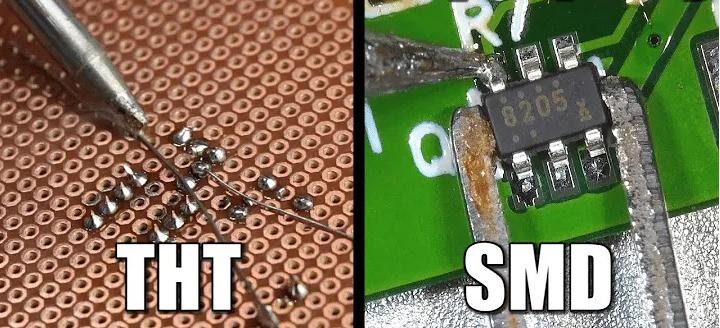

SMT is a modern PCB assembly method where components are mounted directly onto the surface of the board. These components, known as surface-mount devices (SMDs), are small and have flat leads or no leads at all. SMT uses automated machines to place components with precision, followed by reflow soldering to secure them in place.

In HVAC PCB SMT assembly, this method is often preferred for compact designs. Control panels in modern HVAC systems require dense layouts to fit microcontrollers, sensors, and communication modules in limited space. SMT allows for smaller boards, which can reduce the overall size of the control unit.

What Is Through-Hole Technology (THT)?

THT is a traditional PCB assembly method where components have long leads that are inserted through drilled holes in the board. These leads are then soldered on the opposite side, creating a strong mechanical and electrical connection. THT components are larger and often more robust than their SMT counterparts.

For HVAC PCB through-hole assembly, this method is ideal for components that handle high power or need extra durability. In HVAC systems, components like relays, transformers, and power resistors often use THT because they can endure mechanical stress and high current loads.

Key Differences Between SMT and Through-Hole for HVAC PCBs

Both SMT and THT have their place in HVAC control panel assembly, but their differences impact design choices. Below, we compare these technologies across several critical factors relevant to HVAC applications.

1. Size and Space Efficiency

SMT shines in space-constrained designs. Surface-mount components are much smaller, allowing for higher component density on the PCB. In HVAC systems, where control panels are often housed in tight enclosures, SMT enables compact boards. For instance, a typical SMT resistor might measure just 1.6mm x 0.8mm, while a comparable THT resistor could be over 5mm in length.

THT, on the other hand, requires more space due to the larger size of components and the need for drilled holes. This makes it less ideal for modern, sleek HVAC designs but suitable for applications where board size isn’t a primary concern.

2. Durability and Reliability

HVAC systems often operate in harsh environments with temperature swings and vibrations. THT provides superior mechanical strength because the component leads are soldered through the board, creating a robust connection. This makes HVAC PCB through-hole assembly a better choice for high-power components like relays, which might handle currents up to 10A or more in industrial HVAC units.

SMT connections, while reliable for low-power applications, are more prone to failure under mechanical stress. The solder joints are smaller and can crack if the board experiences frequent vibrations or thermal expansion. However, with proper design and materials, SMT can still meet the reliability needs of many HVAC systems.

3. Production Speed and Cost

SMT is highly automated, using pick-and-place machines to position components quickly. This reduces labor costs and speeds up production, making HVAC PCB SMT assembly more cost-effective for large-scale manufacturing. Reflow soldering further streamlines the process by soldering all components in one pass through an oven.

THT often involves more manual labor, especially for inserting components and wave soldering. This increases production time and cost, particularly for complex boards. However, for smaller production runs or prototypes, THT can be more economical since it doesn’t require the same level of automation setup as SMT.

4. Component Availability and Power Handling

While SMT offers a wide range of components for low-power and digital circuits, high-power components are often only available in THT packages. In HVAC control panels, components like power transistors or large capacitors might need to handle voltages above 24V or currents exceeding 5A. THT is typically the go-to choice for these parts due to better heat dissipation and physical stability.

SMT is ideal for integrating microcontrollers and sensors, which are common in smart HVAC systems. These components rarely handle high power, so SMT’s smaller footprint and compatibility with dense layouts make it a perfect fit.

Applications of SMT and Through-Hole in HVAC Control Panels

Understanding where each technology excels helps in designing HVAC control panels that balance performance and cost. Let’s look at specific use cases for each method.

SMT in HVAC Control Panels

Modern HVAC systems often include smart features like remote control, Wi-Fi connectivity, and energy monitoring. These functionalities rely on compact, low-power components such as microcontrollers, LEDs, and small sensors. HVAC PCB SMT assembly is perfect for these applications because it supports high-density designs and allows for smaller, lighter control panels.

For example, a residential HVAC unit might use an SMT-assembled PCB to integrate a temperature sensor, a Bluetooth module, and a small processor on a board smaller than 50mm x 50mm. This compactness is critical for fitting the control panel into a sleek wall-mounted unit.

THT in HVAC Control Panels

In industrial or commercial HVAC systems, control panels often manage high-power loads to drive large motors, compressors, or heating elements. These systems require robust components that can handle significant electrical stress. HVAC PCB through-hole assembly is often used for mounting relays, fuses, and terminal blocks that connect to external wiring.

For instance, a commercial HVAC system might use a THT-assembled PCB to mount a relay capable of switching 240V AC at 10A. The through-hole connection ensures the relay stays securely in place, even under constant vibration from nearby machinery.

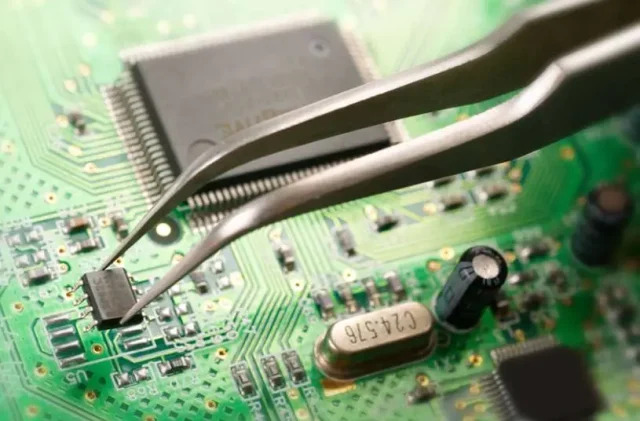

Hybrid Assembly: Combining SMT and THT for Optimal Results

In many HVAC control panels, a hybrid approach combining SMT and THT offers the best of both worlds. This method uses SMT for compact, low-power components and THT for high-power or mechanically stressed parts. Hybrid assembly is common in systems where space efficiency and durability are both priorities.

For example, a hybrid HVAC PCB might feature SMT components for the digital control circuitry (like a microcontroller and sensors) on one section of the board, while using THT for power relays and connectors on another section. This approach maximizes space while ensuring reliability for critical high-power functions.

However, hybrid assembly can increase production complexity. It often requires multiple soldering processes—reflow for SMT and wave or hand soldering for THT—which can raise costs. Careful design and planning are necessary to ensure compatibility between the two methods.

Factors to Consider When Choosing Between SMT and THT

Selecting the right PCB assembly method for your HVAC control panel depends on several factors. Here are the key considerations to guide your decision:

- Environmental Conditions: If the HVAC system operates in a high-vibration or extreme temperature environment, THT may offer better reliability for critical components.

- Power Requirements: High-power components often necessitate THT for better heat management and mechanical stability.

- Size Constraints: For compact designs in residential or portable HVAC units, SMT is usually the better choice due to its space efficiency.

- Production Volume: Large-scale production benefits from SMT’s automation, while small runs or prototypes might be more cost-effective with THT.

- Budget: SMT can reduce costs in high-volume production, but THT might be more economical for smaller projects with fewer automation needs.

Challenges and Solutions in HVAC PCB Assembly

Regardless of the assembly method, HVAC PCB design and manufacturing come with challenges. Here are some common issues and how to address them:

Thermal Management

HVAC systems generate heat, especially in components handling high power. Poor thermal design can lead to overheating and failure. For SMT boards, using thermal vias and heat sinks can help dissipate heat from densely packed components. For THT, selecting components with higher thermal ratings ensures longevity.

Vibration and Mechanical Stress

In industrial HVAC setups, vibrations from motors or fans can loosen components. THT’s stronger mechanical bonds help mitigate this, but for SMT, using conformal coatings or adhesives can secure components against movement.

Signal Integrity

In smart HVAC systems with digital controls, maintaining signal integrity is vital. SMT’s shorter lead lengths reduce impedance and noise, improving signal quality. For instance, SMT layouts can achieve impedance values as low as 50 ohms for high-speed signals, compared to higher values in THT due to longer leads.

Why Partner with a Trusted PCB Assembly Provider?

Designing and assembling PCBs for HVAC control panels requires precision and expertise. Partnering with a reliable provider ensures that your boards meet the specific demands of your application, whether you choose HVAC PCB SMT assembly, HVAC PCB through-hole, or a hybrid approach. A trusted provider can offer advanced manufacturing capabilities, quality assurance, and design support to optimize your control panel’s performance.

From prototyping to mass production, working with an experienced team helps you navigate the complexities of PCB assembly methods. This collaboration ensures that your HVAC systems are efficient, durable, and cost-effective, meeting the needs of your end users.

Conclusion

Choosing between SMT and Through-Hole technologies for HVAC control panel PCB assembly depends on your system’s specific requirements. HVAC PCB SMT assembly excels in compact, high-density designs for modern, smart systems, offering cost savings in large-scale production. Meanwhile, HVAC PCB through-hole provides unmatched durability for high-power components in rugged environments.

By understanding the strengths of each method and considering factors like power needs, space constraints, and environmental conditions, you can make an informed decision. A hybrid approach might even be the ideal solution for balancing compactness and reliability. Whatever your choice, leveraging the right PCB assembly methods ensures that your HVAC control panels deliver consistent performance and long-term value.

With the insights provided in this guide, you’re well-equipped to design or select the best assembly method for your next HVAC project. Prioritize your system’s needs, and explore how advanced manufacturing solutions can bring your vision to life.

ALLPCB

ALLPCB