In the fast-evolving world of autonomous vehicles, integrating advanced sensors and communication systems is critical for safety and performance. Flexible PCBs (Printed Circuit Boards) have emerged as a game-changer in this field, offering unique advantages for sensor integration, space optimization, and reliable connectivity. If you're looking to understand how flexible PCB design for sensors, automotive flexible PCB applications, and related technologies like rigid-flex PCB benefits can transform autonomous vehicle design, you're in the right place. This blog dives deep into the role of flexible PCBs, their benefits, and their applications in autonomous driving systems, including V2V communication PCBs and integrating antennas in PCBs.

What Are Flexible PCBs and Why Do They Matter in Autonomous Vehicles?

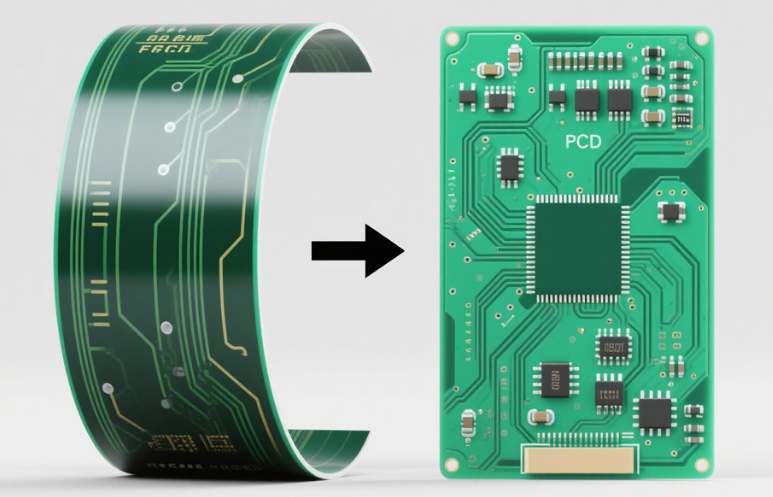

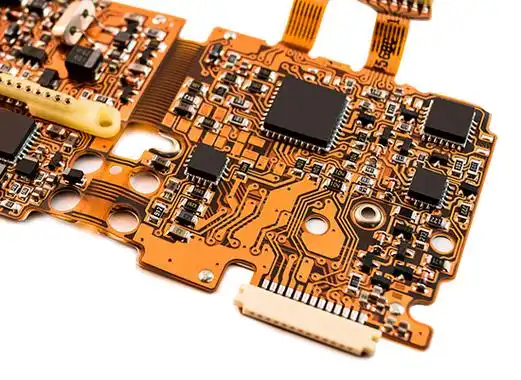

Flexible PCBs are thin, lightweight circuit boards made from flexible materials like polyimide, allowing them to bend and conform to complex shapes. Unlike traditional rigid PCBs, they can fit into tight spaces and withstand vibrations, making them ideal for automotive applications. In autonomous vehicles, where sensors, cameras, and communication systems are packed into compact designs, flexible PCBs provide the adaptability and durability needed for seamless integration.

Autonomous vehicles rely on a network of sensors such as LiDAR, radar, and cameras to navigate and communicate with their surroundings. These components require precise electrical connections that can endure harsh conditions like temperature fluctuations and constant movement. Flexible PCBs meet these demands by offering reliable performance in challenging environments.

Key Benefits of Flexible PCBs in Automotive Sensor Integration

Using flexible PCBs for sensor integration in autonomous vehicles offers several advantages that directly impact design efficiency and performance. Let's explore these benefits in detail.

1. Space Optimization and Compact Design

Autonomous vehicles are packed with electronics, leaving little room for bulky components. Flexible PCBs can be folded or shaped to fit into irregular spaces, reducing the overall footprint of the system. For instance, a sensor module for a front-facing camera can be designed with a flexible PCB that wraps around other components, saving up to 50% more space compared to rigid boards.

2. Enhanced Durability and Reliability

Automotive environments are tough, with constant vibrations and temperature changes. Flexible PCBs are built to handle these conditions, resisting cracks and maintaining signal integrity. Their ability to absorb mechanical stress makes them perfect for mounting sensors in areas prone to movement, ensuring consistent data transmission for critical systems like collision detection.

3. Reduced Weight for Better Efficiency

Weight reduction is a priority in vehicle design to improve fuel efficiency and range, especially for electric autonomous vehicles. Flexible PCBs are significantly lighter than rigid alternatives due to their thin construction, contributing to overall weight savings without sacrificing performance.

Automotive Flexible PCB Applications in Autonomous Vehicles

The use of automotive flexible PCB applications spans various critical systems in autonomous vehicles. Here, we break down some of the most impactful areas where these boards are making a difference.

Sensor Integration for Environmental Awareness

Sensors are the eyes and ears of autonomous vehicles, gathering data on surroundings to enable safe navigation. Flexible PCBs are widely used to connect and power sensors like ultrasonic detectors, LiDAR units, and infrared cameras. Their flexibility allows for direct integration into curved or irregular surfaces, such as the vehicle's bumper or roofline, ensuring a seamless design without compromising functionality.

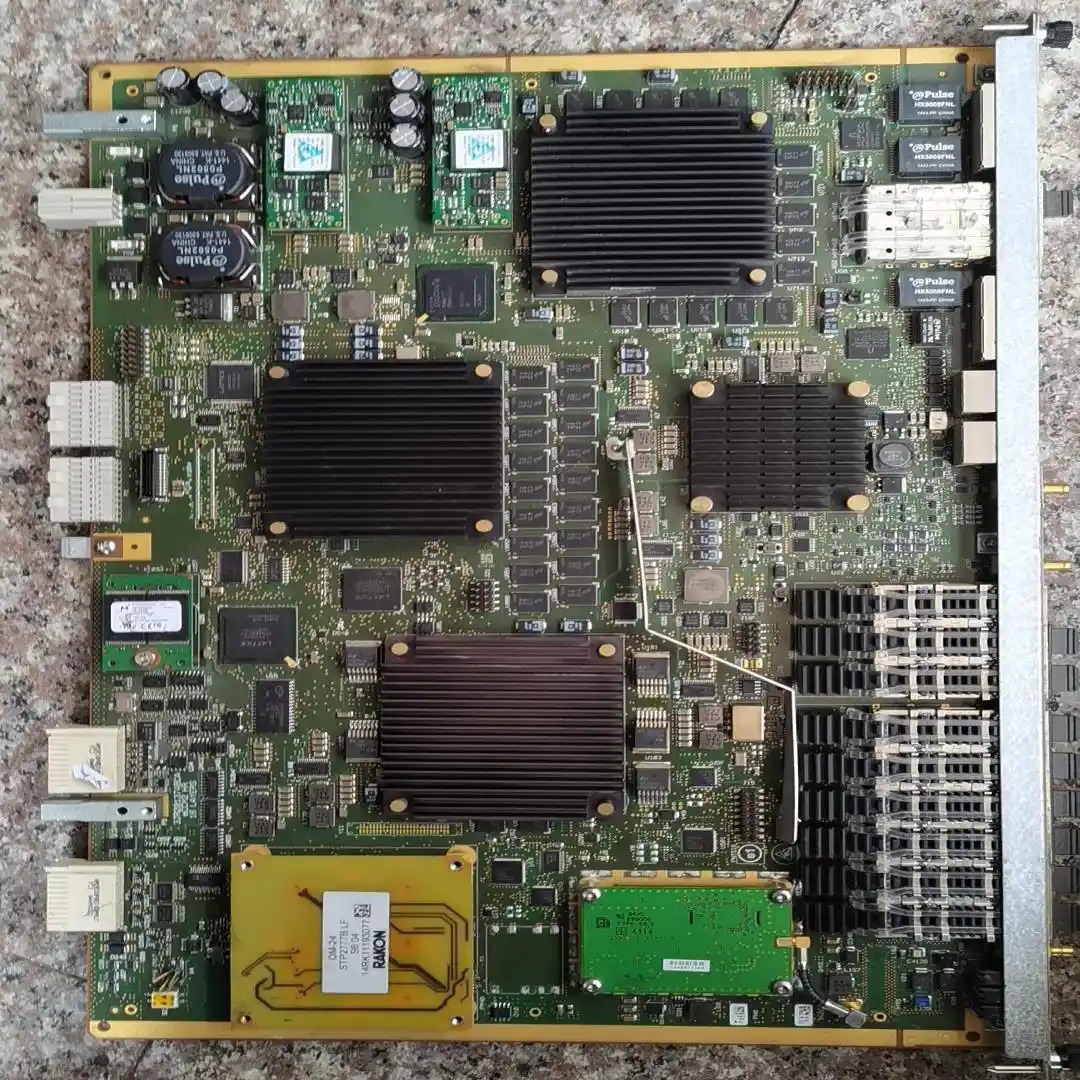

Powering Advanced Driver Assistance Systems (ADAS)

ADAS features like adaptive cruise control and lane departure warnings depend on real-time data from multiple sensors. Flexible PCBs provide the necessary connectivity to link these sensors to central processing units, maintaining low signal latency—often below 1 millisecond—for rapid decision-making.

Supporting Vehicle-to-Vehicle (V2V) Communication

V2V communication PCBs are vital for enabling autonomous vehicles to share data with each other, such as speed, position, and road conditions. Flexible PCBs facilitate the compact design of communication modules, ensuring efficient signal transmission even in high-vibration environments. Their ability to integrate with other components reduces interference, supporting clear communication channels with frequencies often in the 5.9 GHz range for dedicated short-range communications (DSRC).

Rigid-Flex PCB Benefits for Autonomous Vehicle Design

While flexible PCBs are incredibly versatile, combining them with rigid sections creates rigid-flex PCBs, which offer even more advantages for complex automotive systems. Here are some key rigid-flex PCB benefits that make them a top choice for autonomous vehicle design.

1. Combining Stability and Flexibility

Rigid-flex PCBs merge the stability of rigid boards with the adaptability of flexible circuits. This combination is ideal for applications where certain components, like processing chips, need a stable base, while others, like sensor connections, require flexibility to fit into tight spaces. This dual nature reduces the need for additional connectors, cutting down on potential failure points.

2. Improved Signal Integrity

In autonomous vehicles, maintaining signal integrity is critical for accurate data processing. Rigid-flex PCBs minimize signal loss by reducing the number of interconnects, achieving impedance control often within ±10% of the target value (e.g., 50 ohms for high-speed signals). This ensures that data from sensors reaches the control unit without degradation, supporting real-time decision-making.

3. Cost-Effective Assembly

By integrating rigid and flexible sections into a single board, rigid-flex PCBs simplify the assembly process, reducing manufacturing costs. Fewer connectors and cables mean less labor and lower material expenses, which can save up to 30% in production costs for high-volume automotive applications.

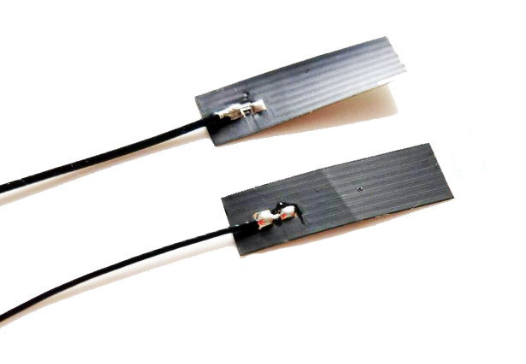

Integrating Antennas in PCBs for Autonomous Vehicles

Antennas are essential for communication systems in autonomous vehicles, enabling GPS, cellular connectivity, and V2V interactions. Integrating antennas in PCBs using flexible or rigid-flex designs offers a compact and efficient solution for these needs.

Why Integrate Antennas into PCBs?

Traditional standalone antennas take up valuable space and can be prone to damage in harsh automotive environments. By embedding antennas directly into flexible PCBs, manufacturers can save space and improve durability. For example, a flexible PCB with an integrated antenna for 5G connectivity can be placed along the vehicle's interior paneling, maintaining a sleek design while ensuring strong signal reception.

Design Considerations for Antenna Integration

Integrating antennas requires careful attention to material selection and layout to avoid interference. Flexible PCBs often use low-loss substrates with dielectric constants around 3.0 to 3.5 to optimize signal performance at frequencies like 28 GHz for 5G applications. Additionally, the antenna design must account for the vehicle's metal body, which can act as a shield or reflector, affecting signal strength.

Challenges in Flexible PCB Design for Autonomous Vehicles

While flexible PCBs offer numerous advantages, their design and implementation come with challenges that engineers must address to ensure optimal performance.

Bend Radius Limitations

Flexible PCBs can only bend to a certain extent before risking damage to conductive traces. A typical minimum bend radius is about 10 times the thickness of the board (e.g., 1.5 mm for a 0.15 mm thick PCB). Exceeding this limit can lead to cracks or signal disruptions, so designers must carefully plan the layout to avoid tight bends in critical areas.

Material Selection for Harsh Environments

Automotive applications expose PCBs to extreme temperatures ranging from -40°C to 85°C, as well as humidity and chemical exposure. Choosing materials with high thermal stability and resistance to degradation is crucial. Polyimide films, for instance, are commonly used for their ability to withstand such conditions while maintaining flexibility.

Signal Integrity at High Frequencies

As autonomous vehicles rely on high-speed data transmission for sensors and communication, maintaining signal integrity becomes more complex. Flexible PCBs must be designed to minimize crosstalk and electromagnetic interference (EMI), often requiring ground planes or shielding layers to protect signals operating at speeds above 1 Gbps.

Future Trends in Flexible PCB Technology for Autonomous Vehicles

The future of flexible PCBs in autonomous vehicle design looks promising, with ongoing advancements poised to enhance their capabilities further. Innovations in materials, such as stretchable substrates, could allow for even greater flexibility, while improved manufacturing techniques may reduce costs. Additionally, the rise of 5G and beyond will drive the need for more sophisticated V2V communication PCBs and antenna integration, pushing the boundaries of what flexible PCBs can achieve.

Conclusion: Why Flexible PCBs Are the Future of Autonomous Vehicle Design

Flexible PCBs are revolutionizing the way autonomous vehicles are designed and built, offering unmatched adaptability, durability, and efficiency for sensor integration and communication systems. From supporting compact flexible PCB design for sensors to enabling automotive flexible PCB applications in tight spaces, these boards are a cornerstone of modern automotive electronics. The rigid-flex PCB benefits further enhance their value by combining stability and flexibility, while advancements in integrating antennas in PCBs pave the way for seamless connectivity in V2V and beyond.

At ALLPCB, we understand the unique demands of autonomous vehicle technology and are committed to providing cutting-edge solutions for your PCB needs. Whether you're designing for sensors, communication modules, or complex antenna systems, leveraging the power of flexible and rigid-flex PCBs can help you stay ahead in this dynamic industry.

ALLPCB

ALLPCB