If you're new to the world of printed circuit boards (PCBs), you might be wondering, "What is PCB impedance, and why does it matter?" In simple terms, PCB impedance is the opposition to the flow of alternating current (AC) in a circuit, influenced by the design of the board's traces and materials. It matters because maintaining the right impedance ensures signals travel without distortion, especially in high-speed electronics. In this guide, we'll break down basic PCB impedance concepts, provide an easy explanation of PCB impedance, and explore why PCB impedance matters for your designs. Whether you're a hobbyist or an aspiring engineer, this blog will help you grasp the essentials and apply them to your projects.

What Is PCB Impedance? An Easy Explanation

Let's start with the basics. Impedance in a PCB context is a measure of how much a circuit resists the flow of alternating current. Unlike resistance, which applies to direct current (DC), impedance includes both resistance and the effects of capacitance and inductance, which come into play with AC signals. Think of it as a "traffic controller" for electrical signals traveling along the traces (conductive paths) on your PCB.

In simpler terms, impedance determines how well a signal can move from one point to another without losing its shape or strength. For example, in a high-speed data circuit like a USB or HDMI interface, if the impedance isn’t matched correctly, the signal might reflect back, causing errors or data loss. A typical impedance value for many high-speed digital signals is 50 ohms, which is a standard for ensuring proper signal transmission.

Basic PCB Impedance Concepts for Beginners

To understand PCB impedance, you need to get familiar with a few key ideas. Don’t worry—we’ll keep this straightforward and practical.

1. Characteristic Impedance

Characteristic impedance is the inherent impedance of a transmission line (like a PCB trace) when it’s infinitely long and unaffected by other nearby traces. It’s determined by the trace’s width, thickness, the distance to the ground plane, and the material of the PCB (known as the dielectric). For instance, a wider trace generally has lower impedance, while a narrower trace increases it. A common target for characteristic impedance in high-speed designs is 50 ohms for single-ended signals or 100 ohms for differential pairs.

2. Signal Integrity

Signal integrity refers to how well a signal maintains its quality as it travels through the PCB. If the impedance isn’t controlled, signals can distort, leading to issues like crosstalk (interference between traces) or ringing (unwanted oscillations). For example, in a circuit operating at 1 GHz, even a small mismatch in impedance can cause significant signal degradation.

3. Transmission Lines

On a PCB, traces that carry high-frequency signals are often treated as transmission lines. These lines need to have a consistent impedance to prevent signal reflections. Imagine sending a wave down a rope—if the rope suddenly changes thickness, the wave bounces back. The same happens with electrical signals on a PCB trace if the impedance isn’t uniform.

4. Dielectric Constant

The dielectric constant (Dk) of the PCB material affects impedance. It measures how much the material slows down electrical signals compared to a vacuum. Most standard PCB materials, like FR-4, have a Dk of about 4.2 to 4.5. A higher Dk means signals travel slower, which impacts impedance calculations. Choosing the right material is crucial for high-speed designs.

Why PCB Impedance Matters

Now that we’ve covered the basics, let’s dive into why PCB impedance matters, especially for beginners working on their first designs. Ignoring impedance can lead to costly mistakes, and understanding it can save you time and frustration.

1. Ensures Signal Quality in High-Speed Designs

In today’s electronics, many devices operate at high speeds—think gigabit Ethernet, DDR memory, or 5G communication. At these frequencies, even tiny mismatches in impedance can cause signal reflections, leading to data errors. For instance, a USB 3.0 connection requires a tightly controlled impedance of 90 ohms for differential pairs to ensure data transfers at 5 Gbps without glitches.

2. Prevents Signal Loss and Interference

When impedance isn’t matched, part of the signal can reflect back toward the source, reducing the energy that reaches the destination. This is called signal loss. Additionally, mismatched impedance can cause electromagnetic interference (EMI), which disrupts nearby circuits. Proper impedance control minimizes these issues, ensuring your device works reliably.

3. Impacts Power Efficiency

In power delivery networks on a PCB, impedance affects how efficiently power is distributed to components. High impedance in power traces can lead to voltage drops, meaning your components might not get the power they need. For example, a microcontroller expecting 3.3V might only receive 3.0V if impedance isn’t managed, leading to erratic behavior.

4. Compliance with Standards

Many industries and protocols have strict impedance requirements. For instance, PCIe (Peripheral Component Interconnect Express) specifies an impedance of 85 ohms for differential pairs. If your PCB doesn’t meet these standards, your product might fail certification or not work with other hardware.

Factors That Affect PCB Impedance

Several design choices influence the impedance of a PCB trace. As a beginner, knowing these factors can help you make better decisions when laying out your board.

1. Trace Width and Thickness

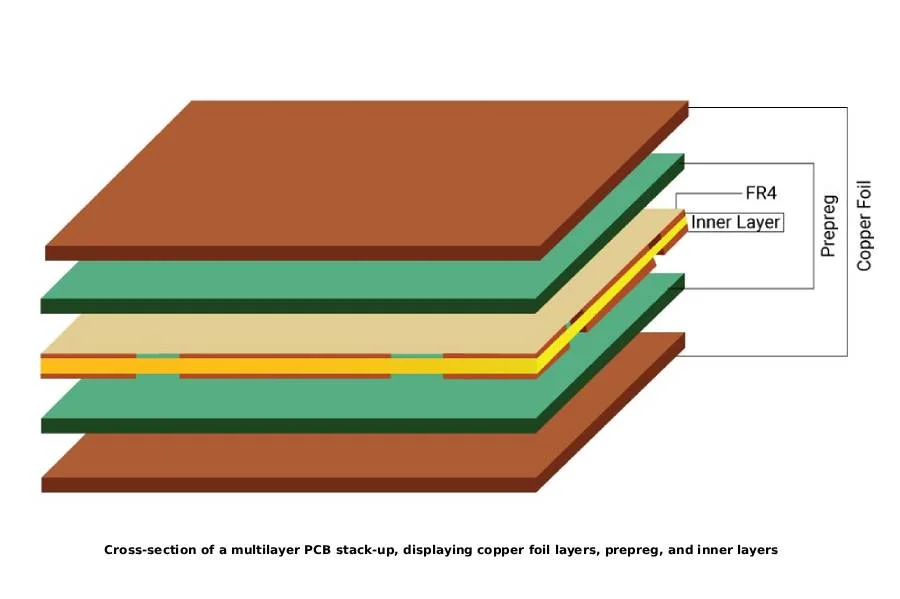

Wider traces have lower impedance, while narrower traces have higher impedance. Similarly, thicker traces (more copper) reduce impedance. For a 50-ohm trace on a standard 1.6mm FR-4 board, you might need a trace width of about 0.3mm, depending on other factors like layer stackup.

2. Distance to Ground Plane

The closer a trace is to the ground plane, the lower its impedance. This is because the electric field between the trace and ground plane becomes stronger. Adjusting the spacing in your PCB stackup can help achieve the desired impedance.

3. Dielectric Material and Thickness

As mentioned earlier, the dielectric constant of the PCB material plays a big role. Thicker dielectric layers increase impedance, while thinner layers decrease it. For high-speed designs, materials with lower Dk values (like Rogers laminates) are often used instead of standard FR-4 to achieve better control.

4. Trace Length and Routing

Longer traces can introduce more inductance, slightly altering impedance. Also, sharp bends or inconsistent routing can disrupt signal flow. It’s best to keep high-speed traces as straight and short as possible.

How to Control Impedance in PCB Design

For beginners, controlling impedance might seem daunting, but it’s manageable with the right approach. Here are some practical steps to get started.

1. Use Impedance Calculators

Many free online tools and software can calculate the required trace width and spacing for a specific impedance value. You input parameters like dielectric constant, board thickness, and target impedance (e.g., 50 ohms), and the tool does the math for you.

2. Follow Design Guidelines

Stick to recommended design rules for high-speed signals. For example, maintain consistent trace widths, avoid sharp corners (use 45-degree angles instead), and keep traces away from noisy components.

3. Work with Your Manufacturer

PCB manufacturers can provide stackup recommendations and material options to meet your impedance needs. Share your target impedance values with them early in the design process to avoid surprises during production.

4. Simulate and Test

Before finalizing your design, use simulation software to check for impedance mismatches. After manufacturing, test your board with an oscilloscope or network analyzer to verify signal integrity. For instance, a time-domain reflectometer (TDR) can measure impedance along a trace to spot inconsistencies.

Common Mistakes to Avoid with PCB Impedance

As a beginner, it’s easy to overlook impedance in your design. Here are some common pitfalls and how to avoid them.

1. Ignoring Impedance for Low-Speed Designs

Even if your circuit isn’t high-speed, impedance can still affect power delivery and analog signals. Don’t assume it’s irrelevant—check your requirements.

2. Inconsistent Trace Widths

Changing trace widths mid-route can cause impedance mismatches. Keep widths uniform for critical signals.

3. Poor Layer Stackup Planning

Not considering the distance to ground planes or using mismatched materials can throw off impedance. Plan your stackup carefully before routing.

4. Overlooking Manufacturing Tolerances

Manufacturing variations can affect trace dimensions and dielectric thickness. Design with some tolerance in mind, and confirm capabilities with your fabricator.

Conclusion: Start Small and Build Your Skills

Understanding PCB impedance is a fundamental skill for anyone diving into electronics design. By grasping basic PCB impedance concepts, recognizing why PCB impedance matters, and following practical tips, you can create boards that perform reliably, even as a beginner. Start with simple designs, use available tools to calculate and simulate impedance, and collaborate with experienced manufacturers to refine your approach.

Remember, impedance isn’t just a technical detail—it’s a key factor in ensuring your signals stay clear, your power delivery is efficient, and your final product works as intended. With practice, managing impedance will become second nature, opening the door to more complex and exciting projects.

ALLPCB

ALLPCB