In today’s fast-paced electronics industry, building a sustainable PCB supply chain is more important than ever. As environmental concerns and ethical standards take center stage, companies are under pressure to adopt responsible practices. A sustainable PCB supply chain focuses on minimizing environmental impact, ensuring ethical sourcing, and fostering transparency through supplier collaboration. At ALLPCB, we believe that collaboration and transparency are the cornerstones of creating a responsible PCB supply chain management system. In this blog, we’ll dive deep into how these principles can transform the industry, offering actionable insights for businesses and engineers looking to make a difference.

What Is a Sustainable PCB Supply Chain?

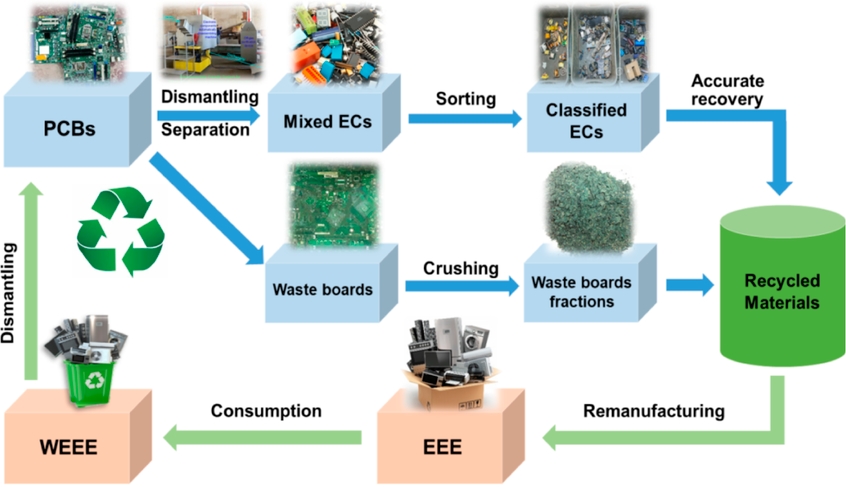

A sustainable PCB supply chain refers to the process of designing, sourcing, manufacturing, and distributing printed circuit boards (PCBs) in a way that reduces environmental harm, upholds ethical labor practices, and ensures long-term viability. This involves everything from using eco-friendly materials to partnering with suppliers who share the same commitment to sustainability. By focusing on transparent PCB sourcing and ethical PCB manufacturing practices, businesses can build trust with customers and contribute to a greener future.

The journey to sustainability isn’t just about meeting regulations—it’s about creating value for all stakeholders, from manufacturers to end-users. Let’s explore the key components that make a PCB supply chain sustainable and how collaboration and transparency play a vital role.

The Importance of Collaboration in Building Sustainability

Collaboration is the backbone of a sustainable PCB supply chain. No single company can achieve sustainability on its own—it requires strong partnerships with suppliers, manufacturers, and even customers. Supplier collaboration for sustainability means working together to set clear goals, share best practices, and solve challenges as a team.

For instance, collaborating with raw material suppliers to source lead-free or recyclable materials can significantly reduce the environmental footprint of PCB production. According to industry data, using lead-free solder can cut down hazardous waste by up to 30% in some manufacturing processes. Additionally, joint efforts to optimize logistics can lower carbon emissions—studies suggest that streamlined supply chain logistics can reduce CO2 emissions by 15-20%.

Collaboration also extends to sharing knowledge. By conducting joint workshops or training programs, companies can ensure that all partners understand the importance of ethical PCB manufacturing practices. This creates a ripple effect, encouraging smaller suppliers to adopt sustainable methods as well.

Transparency: The Key to Trust and Accountability

Transparency in the PCB supply chain builds trust with customers and ensures accountability at every stage. Transparent PCB sourcing means openly sharing information about where materials come from, how they are processed, and whether they meet environmental and ethical standards. This level of openness is critical in an industry where customers increasingly demand proof of responsible practices.

One way to achieve transparency is through detailed reporting. Companies can publish sustainability reports that outline their sourcing practices, waste management strategies, and energy consumption data. For example, disclosing that 80% of raw materials are sourced from certified eco-friendly suppliers can boost customer confidence. Additionally, using digital tools like blockchain technology can provide a verifiable record of a product’s journey from raw material to finished PCB, ensuring every step is traceable.

Transparency also helps identify areas for improvement. If a supplier’s practices fall short of ethical standards, transparent communication allows for quick corrective action. This not only protects the environment but also safeguards a company’s reputation in the long run.

Ethical PCB Manufacturing Practices for a Better Future

Ethical PCB manufacturing practices are a cornerstone of a sustainable supply chain. This means prioritizing worker safety, fair labor conditions, and environmentally friendly production methods. It’s about doing what’s right, not just what’s required by law.

For example, reducing the use of harmful chemicals like brominated flame retardants in PCB production can significantly lower health risks for workers and environmental pollution. Industry reports indicate that switching to water-based cleaning agents instead of solvent-based ones can reduce volatile organic compound (VOC) emissions by up to 50%. Additionally, implementing energy-efficient machinery can cut power consumption during manufacturing by 10-15%, contributing to lower greenhouse gas emissions.

Ethical practices also involve ensuring fair wages and safe working conditions for all employees across the supply chain. Partnering with suppliers who adhere to international labor standards, such as those set by the International Labour Organization (ILO), is a crucial step. This not only improves worker well-being but also enhances product quality, as a motivated workforce is more likely to maintain high standards.

Steps to Build a Responsible PCB Supply Chain Management System

Creating a responsible PCB supply chain management system requires a strategic approach. Here are actionable steps to guide businesses in this journey:

1. Assess Current Practices

Start by evaluating your existing supply chain. Identify areas where environmental impact is high or where ethical standards may not be met. For instance, check if your suppliers use conflict-free minerals or if manufacturing processes generate excessive waste. Use tools like sustainability audits to gather accurate data—some audits reveal that up to 25% of PCB production waste can be recycled with the right processes in place.

2. Set Clear Sustainability Goals

Define measurable targets, such as reducing carbon emissions by 20% over five years or achieving 100% recyclable packaging by a specific date. These goals provide a roadmap for improvement and help align all stakeholders toward a common purpose.

3. Partner with Like-Minded Suppliers

Choose suppliers who share your commitment to sustainability. Conduct thorough vetting processes to ensure they follow ethical sourcing and manufacturing practices. Long-term partnerships based on shared values can lead to innovations, such as developing new eco-friendly PCB materials.

4. Invest in Technology

Leverage technology to improve transparency and efficiency. Automated systems can monitor energy usage in real-time, helping to cut consumption by up to 10% in some cases. Digital platforms can also facilitate better communication with suppliers, ensuring everyone stays informed about sustainability targets.

5. Educate and Engage Stakeholders

Train employees and suppliers on the importance of sustainable practices. Share success stories to inspire action—for example, highlight how a switch to renewable energy sources reduced production costs by 8% while cutting emissions. Engaged stakeholders are more likely to contribute to sustainability efforts.

Challenges in Achieving a Sustainable PCB Supply Chain

While the benefits of a sustainable PCB supply chain are clear, there are challenges to overcome. One major hurdle is the cost of implementing green technologies or sourcing eco-friendly materials. For small and medium-sized enterprises, the initial investment can be significant, even though long-term savings often outweigh these costs. Data shows that energy-efficient equipment can save up to 12% on operational costs over a decade, but upfront expenses remain a barrier.

Another challenge is ensuring compliance across global supply chains. Different regions have varying regulations, making it difficult to maintain consistent standards. For instance, stricter chemical usage laws in some countries may not apply elsewhere, creating gaps in ethical practices. Overcoming this requires robust supplier agreements and regular audits.

Finally, there’s the issue of limited awareness. Some suppliers or customers may not fully understand the importance of sustainability, leading to resistance. Addressing this through education and demonstrating the tangible benefits—like improved brand reputation or cost savings—can help shift perspectives.

The Role of Industry Standards and Certifications

Industry standards and certifications play a crucial role in promoting a sustainable PCB supply chain. Certifications like ISO 14001 for environmental management or RoHS (Restriction of Hazardous Substances) compliance ensure that companies adhere to strict guidelines. Achieving RoHS compliance, for instance, means limiting the use of six hazardous materials in PCB production, reducing environmental harm by significant margins.

Certifications also provide a competitive edge. Customers are more likely to trust companies that can prove their commitment to sustainability through recognized standards. Additionally, adhering to these guidelines can streamline operations, as they often encourage waste reduction and energy efficiency—leading to savings of up to 5-10% on production costs in some reported cases.

How ALLPCB Leads the Way in Sustainability

At ALLPCB, we are committed to building a sustainable PCB supply chain through collaboration and transparency. Our approach involves partnering with suppliers who prioritize ethical practices and using advanced technologies to minimize waste. We strive to ensure that every step of our process, from material sourcing to final delivery, aligns with environmental and social responsibility goals.

We also focus on continuous improvement. By regularly auditing our supply chain and investing in eco-friendly innovations, we aim to set a benchmark for responsible PCB supply chain management. Our dedication to transparency means that our customers always know where their products come from and how they are made, fostering trust and loyalty.

Conclusion: Building a Greener Future Together

Creating a sustainable PCB supply chain is not just a trend—it’s a necessity for the future of the electronics industry. Through supplier collaboration for sustainability, transparent PCB sourcing, and ethical PCB manufacturing practices, businesses can reduce their environmental impact while meeting the growing demand for responsible products. At ALLPCB, we believe that every step toward sustainability counts, and we’re proud to lead the way in this transformation.

By adopting the strategies outlined in this blog, companies can build a responsible PCB supply chain management system that benefits both the planet and their bottom line. Let’s work together to create a greener, more ethical future for PCB manufacturing, one collaboration at a time.

ALLPCB

ALLPCB