In the world of electronics manufacturing, compliance with regulations like REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is critical. If you're involved in Surface Mount Technology (SMT) assembly, you might be wondering how REACH compliance affects the SMT process. Simply put, REACH imposes restrictions on certain chemicals used in materials, components, and soldering processes, pushing manufacturers to adopt safer alternatives and maintain detailed documentation. This can impact everything from component selection to soldering techniques in SMT assembly.

In this comprehensive overview, we'll dive deep into the specifics of REACH compliance and its influence on surface mount assembly. We'll explore how these regulations shape the SMT process, the challenges they pose, and actionable strategies to ensure compliance without sacrificing efficiency or quality. Whether you're a design engineer or a production manager, this guide will help you navigate the complexities of REACH in SMT assembly.

What is REACH and Why Does It Matter for SMT Assembly?

REACH is a regulation enforced by the European Union (EU) to protect human health and the environment from hazardous chemicals. Introduced in 2007, it applies to all companies that manufacture, import, or use chemicals in the EU market. For electronics manufacturers, REACH compliance is non-negotiable if you plan to sell products in Europe. It directly affects the materials and processes used in surface mount assembly, including the chemicals in solder pastes, fluxes, and even the components mounted on printed circuit boards (PCBs).

The regulation maintains a list of Substances of Very High Concern (SVHCs), which are chemicals that may pose risks such as cancer, reproductive harm, or environmental damage. If a substance is on this list, companies must report its use, seek authorization, or find safer alternatives. For SMT assembly, this means scrutinizing every material and component to ensure compliance, which can add layers of complexity to the production process.

How REACH Impacts the SMT Process

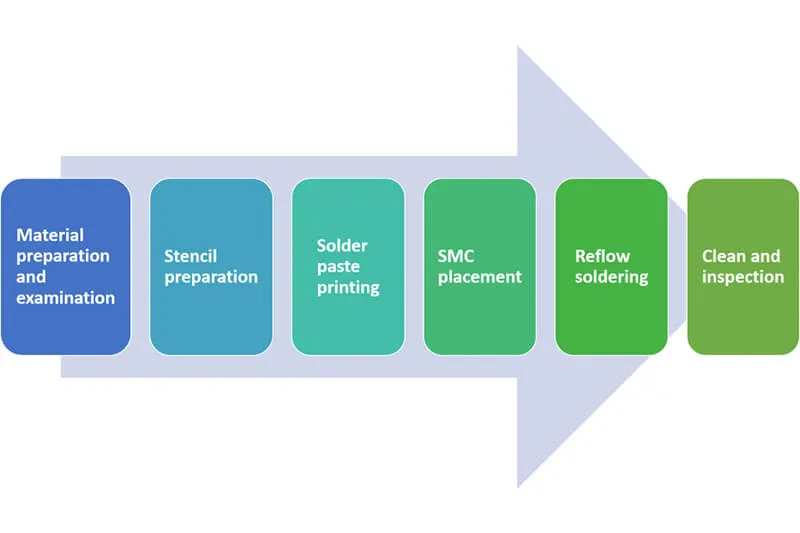

REACH compliance influences several aspects of the SMT process, from component selection to soldering techniques. Below, we'll break down the key areas where these regulations come into play and how they affect surface mount assembly.

1. Component Restrictions Under REACH

One of the primary ways REACH impacts SMT assembly is through restrictions on components. Many electronic components, such as resistors, capacitors, and integrated circuits, may contain materials listed as SVHCs. For example, lead (Pb) is a common material in some component finishes and solders, but it is restricted under REACH due to its toxicity. Manufacturers must ensure that components meet REACH thresholds—typically less than 0.1% by weight for SVHCs—or seek exemptions for specific uses.

This restriction forces SMT assembly teams to source REACH-compliant components, which can sometimes be more expensive or harder to find. Additionally, suppliers must provide detailed documentation, such as material declarations, to confirm compliance. Failure to verify component compliance can result in production delays, fines, or even product recalls.

2. REACH Impact on Soldering Processes

Soldering is at the heart of SMT assembly, and REACH has a significant impact on this process. Traditional soldering materials, like lead-based solders, are heavily restricted under REACH and related regulations like RoHS (Restriction of Hazardous Substances). While RoHS often takes the spotlight in electronics, REACH adds another layer of scrutiny by targeting additional chemicals used in fluxes and solder pastes.

For instance, certain solvents and activators in fluxes might contain SVHCs, requiring manufacturers to switch to alternative formulations. These alternatives must still meet performance standards, such as ensuring strong solder joints and minimal defects during reflow soldering. Transitioning to new materials can involve retooling equipment, adjusting reflow profiles (e.g., peak temperatures around 240-260°C for lead-free solders), and conducting extensive testing to maintain quality.

3. Documentation and Traceability Challenges

REACH compliance in the SMT process isn't just about materials—it's also about documentation. Companies must keep detailed records of the substances used in their products and supply chains. This includes maintaining a Bill of Materials (BoM) with REACH-compliant data for every component and material used in assembly. For large-scale SMT operations handling thousands of components per hour, this level of traceability can be daunting.

Implementing robust traceability systems, such as barcode scanning or Manufacturing Execution Systems (MES), can help streamline compliance efforts. These tools track materials from procurement to final assembly, ensuring that no non-compliant substances slip through the cracks. However, setting up such systems often requires upfront investment and staff training.

Challenges of REACH Compliance in SMT Assembly

While REACH aims to create safer products and environments, it introduces several challenges for SMT assembly. Understanding these hurdles is the first step toward overcoming them.

1. Increased Costs and Supply Chain Delays

Sourcing REACH-compliant components and materials often comes with a higher price tag. Lead-free solders, for example, can cost 20-30% more than traditional lead-based options due to the use of alternative metals like tin, silver, and copper. Additionally, suppliers may face delays in providing compliant materials or documentation, slowing down the SMT assembly timeline. For manufacturers operating on tight margins, these added costs and delays can strain budgets and schedules.

2. Performance Trade-Offs with Alternative Materials

Switching to REACH-compliant materials doesn't always guarantee the same performance as traditional options. For instance, lead-free solders have a higher melting point (around 217-220°C compared to 183°C for leaded solders), which can stress components and PCBs during reflow. This may lead to issues like thermal damage or weaker solder joints if not managed properly. SMT assembly teams must invest time in optimizing processes to mitigate these risks, often through trial and error.

3. Regulatory Complexity and Updates

REACH is a dynamic regulation, with the SVHC list updated regularly—often twice a year. Keeping up with these changes requires constant vigilance, as a material deemed safe today could be restricted tomorrow. For SMT assembly operations, this means continuously monitoring regulatory updates and adjusting supply chains accordingly. Smaller manufacturers may struggle with the resources needed to stay compliant, risking penalties or market exclusion.

Strategies for Navigating REACH Compliance in SMT Assembly

Despite the challenges, there are practical steps you can take to ensure REACH compliance without disrupting your SMT process. Here are some actionable strategies to consider.

1. Partner with Compliant Suppliers

Building strong relationships with suppliers who prioritize REACH compliance is essential. Request detailed material declarations and SVHC reports for all components and soldering materials before procurement. Establishing a network of trusted suppliers can reduce the risk of non-compliance and streamline the documentation process.

2. Invest in Training and Tools

Equip your team with the knowledge and tools needed to handle REACH compliance. Conduct regular training sessions to keep staff updated on regulatory changes and best practices for SMT assembly. Additionally, invest in software solutions that automate compliance tracking and integrate with your existing production systems. These tools can save time and reduce human error in managing complex data.

3. Optimize Soldering Processes for Lead-Free Materials

To address the REACH impact on soldering, fine-tune your reflow profiles for lead-free solders. Adjust peak temperatures and dwell times to prevent thermal stress on components—typically maintaining a time above liquidus (TAL) of 60-90 seconds. Use advanced inspection techniques, such as Automated Optical Inspection (AOI), to detect soldering defects early and ensure consistent quality in your SMT assembly line.

4. Stay Proactive with Regulatory Monitoring

Keep a close eye on REACH updates by subscribing to alerts from the European Chemicals Agency (ECHA) or industry associations. Assign a dedicated compliance officer or team to review changes to the SVHC list and assess their impact on your SMT process. Being proactive allows you to adapt quickly and avoid last-minute disruptions.

Benefits of REACH Compliance for SMT Assembly

While REACH compliance poses challenges, it also offers long-term benefits for SMT assembly operations. Embracing these regulations can position your company as a leader in sustainable manufacturing.

1. Access to the EU Market

Compliance with REACH ensures that your products can be sold in the EU, one of the largest markets for electronics. This opens up significant business opportunities and helps you stay competitive on a global scale.

2. Improved Safety and Sustainability

By eliminating hazardous substances from your SMT process, you're contributing to safer working conditions for employees and reducing environmental impact. This aligns with growing consumer demand for eco-friendly products and can enhance your brand reputation.

3. Future-Proofing Your Operations

Adapting to REACH now prepares your SMT assembly line for future regulations. As governments worldwide tighten chemical restrictions, early compliance gives you a head start in meeting evolving standards.

Conclusion: Embracing REACH for a Better SMT Future

REACH compliance is a complex but necessary aspect of modern SMT assembly. While it introduces challenges like component restrictions, soldering adjustments, and increased costs, it also drives innovation and sustainability in the electronics industry. By understanding the REACH impact on soldering and surface mount assembly, and by implementing strategic solutions, manufacturers can turn compliance into a competitive advantage.

At ALLPCB, we're committed to supporting your journey through REACH compliance with high-quality, compliant materials and expert guidance. Whether you're sourcing components or optimizing your SMT process, staying ahead of regulations like REACH ensures that your products meet global standards without compromising on performance. Let's build a safer, more sustainable future for electronics manufacturing together.

ALLPCB

ALLPCB