Overview

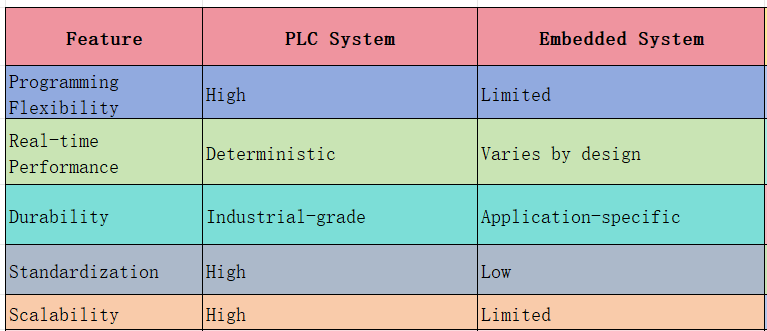

Embedded systems are widely used across many fields, from aerospace and medical devices to industrial control and smart home applications. As application scenarios become more complex and more critical, the reliability of embedded systems becomes essential. The embedded motherboard, as the core component of the system, directly affects overall system stability and lifetime. Designing a high-reliability embedded motherboard is both a technical challenge and a key factor in product robustness. This article examines key aspects of high-reliability embedded motherboard design, including hardware selection, redundancy and fault tolerance, thermal design, electromagnetic compatibility (EMC), software optimization, and reliability testing, to provide practical reference for designers.

1. Hardware Selection and Quality Control

The foundation of a high-reliability embedded motherboard is high-quality hardware. Selecting appropriate components and implementing strict quality control are the first steps to ensuring system reliability.

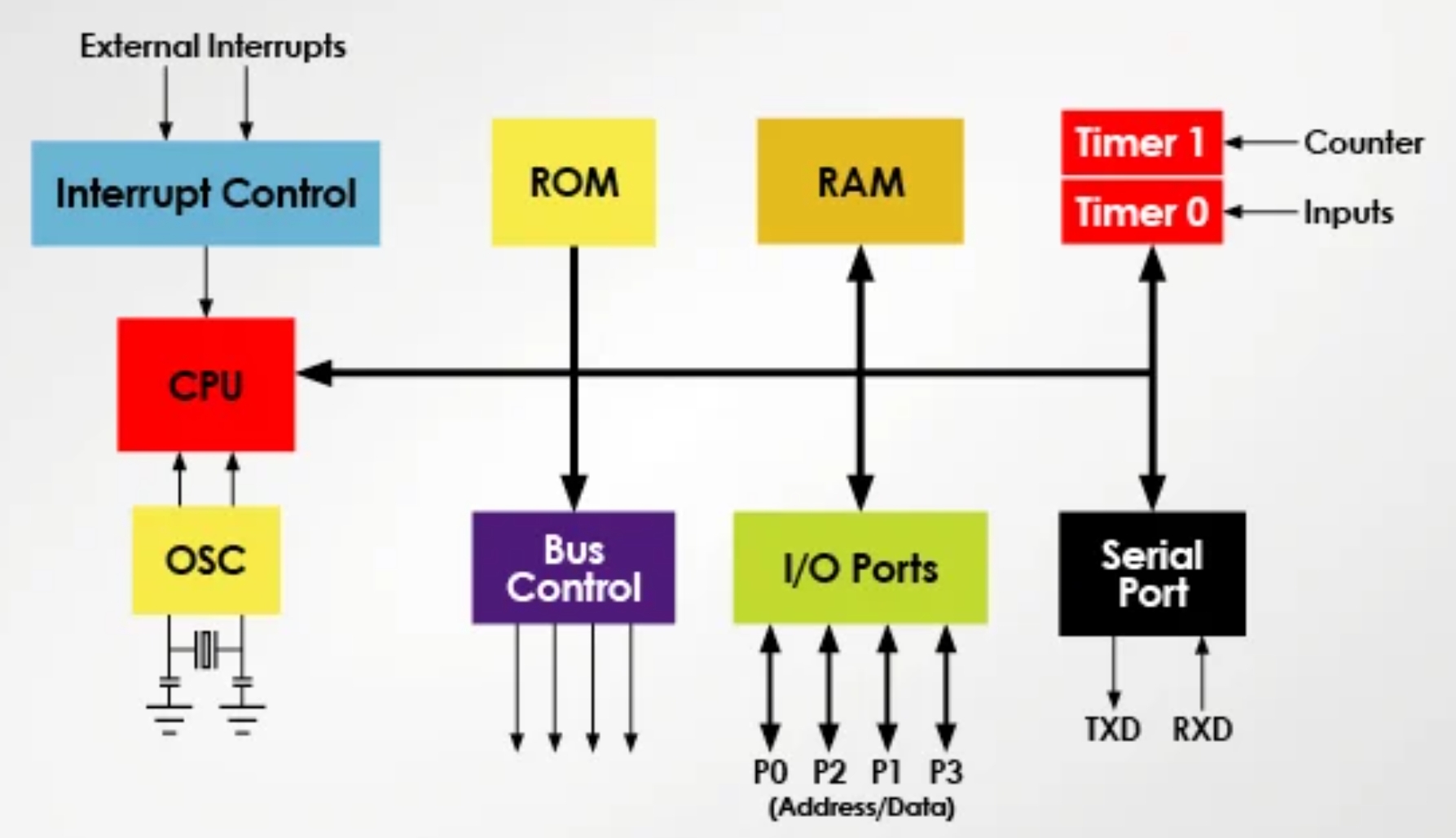

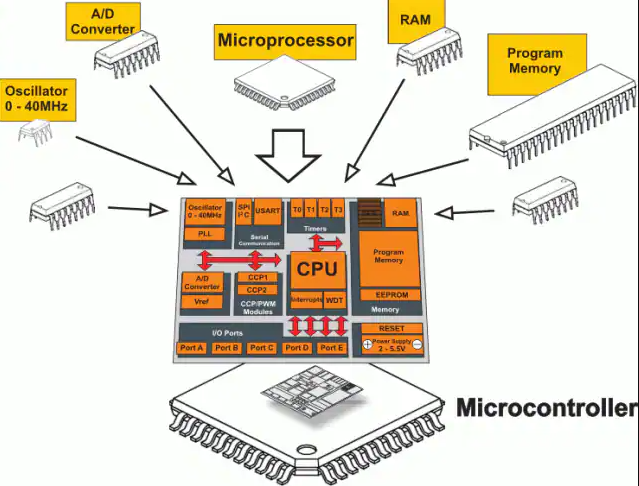

- Processors and chipsets: Choose industrial-grade or military-grade certified processors and chipsets. These components undergo stricter tests for temperature, humidity, and vibration and can operate reliably in harsher environments. Evaluate processor and chipset performance metrics carefully and select models with sufficient headroom to handle unexpected load spikes.

- Memory: Use memory with ECC (error correcting code) to correct single-bit errors and improve data integrity. For long-term data storage, choose flash memory with wear-leveling technologies, such as SLC NAND flash or eMMC, to extend memory lifetime.

- Power management ICs: The power subsystem is critical to system stability. Select power management ICs with high efficiency, low noise, overvoltage protection, overcurrent protection, and short-circuit protection. Also choose power supplies with sufficient power margin to avoid overload.

- Connectors and interfaces: Use high-reliability connectors and interfaces, for example connectors with locking mechanisms to ensure stable connections. For interfaces susceptible to interference, such as serial ports and Ethernet, apply appropriate isolation and filtering.

- Printed circuit board: The printed circuit board is the substrate that interconnects all components. Use high-quality PCB materials, such as FR-4 or higher-grade materials, to ensure mechanical strength and electrical performance. PCB layout and routing should follow EMC design principles to minimize electromagnetic interference.

- Bill of materials (BOM) management: Implement a robust BOM management system to ensure traceability of all components. Select reliable suppliers and perform regular supplier audits to ensure component quality meets requirements.

2. Redundancy Design and Fault Tolerance

Redundancy design adds extra components or modules so that backups can take over if primary components fail, ensuring continued operation. Fault tolerance refers to the system's ability to detect and correct errors to maintain reliability.

- Power redundancy: Use dual or multiple power supply redundancy so that if the primary supply fails, backup supplies automatically take over and maintain uninterrupted power.

- Network redundancy: Use dual or multiple NIC redundancy so that if the primary network interface fails, backup interfaces automatically switch over to maintain network connectivity. Various redundancy protocols can be used, for example link aggregation and VRRP (virtual router redundancy protocol).

- Storage redundancy: Use RAID (redundant array of independent disks) technologies to provide redundant storage so data is not lost when a drive fails.

- Processor redundancy: For extremely high-reliability applications, consider dual-processor or multi-processor redundancy so backup processors can take over if the primary processor fails.

- Fault detection and recovery: Implement robust fault detection mechanisms, such as watchdog timers to detect system deadlocks and heartbeat mechanisms to monitor process status. When a fault is detected, the system should support automatic recovery actions, such as restarting the system or switching to backup components.

3. Thermal Design and Temperature Control

Temperature is a major factor affecting electronic component lifetime. Excessive temperature can degrade performance, shorten life, or damage components. Effective thermal design is essential for high-reliability embedded motherboards.

- Component selection: Choose low-power components to reduce heat generation.

- Heatsink design: Select appropriate heatsinks based on component power dissipation and ambient temperature. Heatsink material, size, and shape all affect thermal performance.

- Fan design: For higher-power components, use fans for forced convection. Select low-noise, high-reliability fans and schedule regular maintenance.

- Thermal interface materials: Apply thermal grease or other thermal interface materials between components and heatsinks to improve heat transfer.

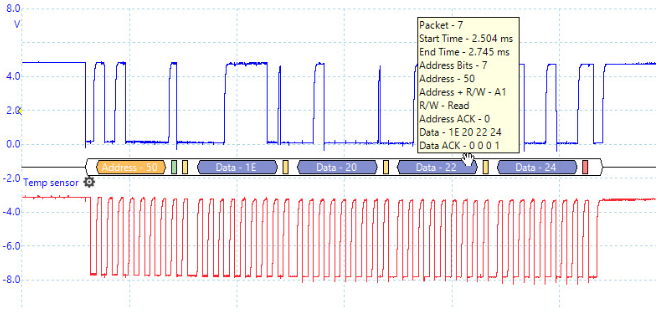

- Temperature monitoring: Place temperature sensors at key locations to monitor system temperature in real time. When thresholds are exceeded, the system can take measures such as reducing CPU frequency or increasing cooling.

- Natural convection: Arrange PCB layout to take advantage of natural convection, for example placing high-heat components in locations with good airflow.

4. Electromagnetic Compatibility (EMC) Design

Electromagnetic compatibility is the ability of electronic equipment to operate properly in an electromagnetic environment and not to interfere with other equipment. Good EMC design reduces electromagnetic interference and improves system reliability.

- Grounding design: Use proper grounding schemes, such as multi-point grounding or star grounding, to reduce electromagnetic noise on ground lines.

- Shielding: Use shields or enclosures to block electromagnetic radiation and prevent interference.

- Filtering: Add filters on power and signal lines to remove high-frequency noise.

- Routing: Follow EMC routing principles in PCB layout, such as minimizing loop area and controlling signal line impedance.

- Electrostatic discharge (ESD) protection: Add ESD protection devices to input/output ports to prevent damage from electrostatic discharges.

5. Software Optimization and Real-Time Behavior

Software is a vital part of embedded systems. Good software design improves system reliability and performance.

- Modular design: Use modular architecture to break the system into independent modules, improving maintainability and reusability.

- Error handling: Implement comprehensive error handling to detect and manage errors such as null pointer exceptions and memory leaks.

- Real-time behavior: For applications requiring real-time response, use a real-time operating system (RTOS) to ensure tasks execute on schedule.

- Resource management: Manage system resources such as memory and file descriptors carefully to avoid leaks.

- Code review: Conduct regular code reviews to identify potential bugs and vulnerabilities.

6. Reliability Testing and Verification

Reliability testing is a key method for validating system reliability. Various tests can reveal potential issues so they can be addressed.

- Environmental testing: Perform high/low temperature, vibration, shock, and humidity tests to validate reliability under harsh conditions.

- Lifetime testing: Conduct long-duration operation tests to verify system lifetime.

- Stress testing: Run high-load tests to verify stability under heavy workload.

- Compatibility testing: Test interoperability with other devices to verify compatibility.

- Functional testing: Test system functions to ensure they operate correctly.

- Burn-in testing: Perform component burn-in tests to detect potential early-life failures.

7. Reliability Maintenance and Management

Even with a high-reliability design, ongoing maintenance and management are required to ensure long-term stable operation.

- Scheduled maintenance: Perform regular maintenance such as cleaning heatsinks, inspecting connectors, and updating software.

- Failure logging and analysis: Maintain comprehensive failure logs documenting causes and resolutions. Analyzing these logs helps identify systemic issues and guide improvements.

- Version control: Use version control for both software and hardware to facilitate traceability and maintenance.

- Remote monitoring: For remotely deployed systems, use remote monitoring to track system status in real time.

- User training: Train users to improve their understanding and operation of the system, reducing operator errors.

Conclusion

Designing a high-reliability embedded motherboard is a complex, multidisciplinary effort. From hardware selection and redundancy to thermal and EMC design, each aspect is critical. Through careful design and rigorous testing, stable and reliable embedded motherboards can be achieved to support a wide range of applications. As embedded technologies evolve, demand for high-reliability designs will continue to grow. Continuous learning and refinement of design practices are necessary for designers to meet these challenges and improve system reliability across diverse and critical application scenarios.

ALLPCB

ALLPCB