In the fast-evolving world of electronics, lead-free assembly certification has become a critical requirement for PCB manufacturers aiming to meet global standards and regulations. If you're searching for clarity on lead-free assembly certification checklist requirements or how to comply with RoHS in PCB assembly, you're in the right place. This guide offers a detailed roadmap to understanding lead-free assembly certification requirements, adhering to IPC lead-free assembly standards, and mastering the lead-free PCB manufacturing process.

Whether you're a seasoned manufacturer or new to the field, navigating these certifications can seem daunting. That’s why we've crafted this comprehensive resource to break down every aspect of the process. From essential checklists to actionable steps for RoHS compliance, this blog will equip you with the knowledge to ensure your products meet industry benchmarks and environmental regulations.

Why Lead-Free Assembly Certification Matters for PCB Manufacturers

Lead-free assembly certification is more than just a regulatory hurdle; it’s a commitment to environmental safety and product reliability. With the introduction of the Restriction of Hazardous Substances (RoHS) directive in 2006, the use of lead and other harmful materials in electronics has been heavily restricted, especially in the European Union. Non-compliance can lead to restricted market access, hefty fines, and damage to your reputation.

Beyond legal requirements, adopting lead-free processes signals to customers that your business prioritizes sustainability and quality. Certifications based on IPC lead-free assembly standards also ensure that your manufacturing processes meet rigorous quality and performance benchmarks, giving you a competitive edge in the global market.

Understanding Lead-Free Assembly Certification Requirements

The journey to achieving lead-free assembly certification starts with understanding the core requirements. These requirements are often shaped by international regulations like RoHS and industry standards set by organizations such as the Institute of Printed Circuits (IPC). Below, we outline the key elements you need to focus on.

1. Compliance with RoHS Directives

RoHS compliance in PCB assembly is non-negotiable for manufacturers targeting markets in the EU and beyond. The directive limits the use of six hazardous materials, including lead, to less than 0.1% by weight in homogeneous materials. To meet RoHS standards, manufacturers must:

- Use lead-free solder materials, typically tin-silver-copper (SAC) alloys like SAC305, which contains 3% silver and 0.5% copper.

- Source components and materials from suppliers who provide RoHS-compliant declarations.

- Implement strict documentation to track material composition across the supply chain.

2. Adherence to IPC Lead-Free Assembly Standards

The IPC sets globally recognized standards for electronics manufacturing, including specific guidelines for lead-free assembly. Key standards to follow include:

- IPC-A-610: This standard covers the acceptability of electronic assemblies, with specific criteria for lead-free soldering quality. For instance, it defines acceptable fillet shapes and wetting angles for lead-free solder joints.

- IPC J-STD-001: Focuses on the requirements for soldered electrical and electronic assemblies, including lead-free processes. It specifies training and certification for operators to handle lead-free materials.

- IPC-6012: Addresses the qualification and performance of rigid printed boards, ensuring that lead-free materials maintain structural integrity under thermal stress.

Meeting these standards often requires investing in training programs for staff and upgrading equipment to handle the higher melting points of lead-free solders, which can reach up to 220°C compared to 183°C for traditional lead-based solders.

Lead-Free Assembly Certification Checklist: A Step-by-Step Approach

To simplify the certification process, we've compiled a practical lead-free assembly certification checklist. Use this as a roadmap to ensure no detail is overlooked.

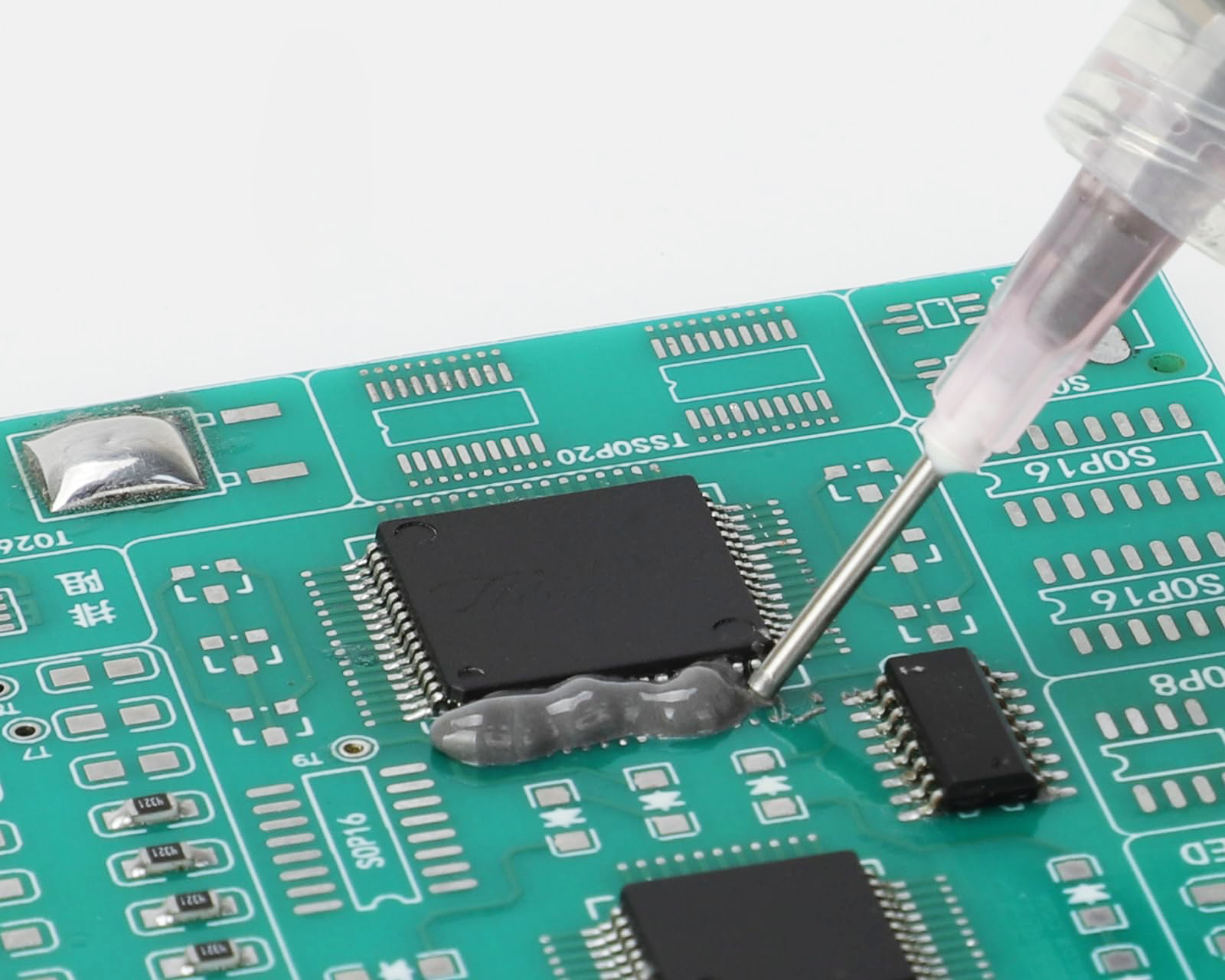

Step 1: Material Selection and Verification

- Confirm that all solder pastes, components, and finishes (like ENIG or HASL lead-free) comply with RoHS limits.

- Request Material Safety Data Sheets (MSDS) and compliance certificates from suppliers.

- Test incoming materials using X-ray fluorescence (XRF) analyzers to detect lead content.

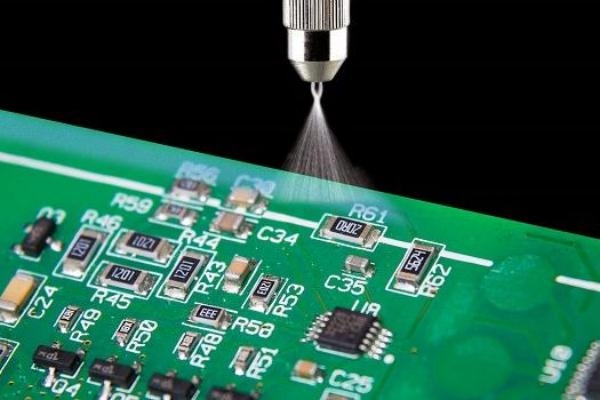

Step 2: Process Adaptation for Lead-Free Manufacturing

- Adjust reflow soldering profiles to accommodate higher temperatures, typically setting peak temperatures between 235°C and 260°C for SAC alloys.

- Ensure proper storage of lead-free materials to prevent oxidation, as they are more sensitive to moisture.

- Implement nitrogen atmospheres during reflow to reduce defects like voiding in solder joints.

Step 3: Equipment and Tooling Upgrades

- Use soldering irons and reflow ovens rated for higher temperatures required by lead-free solders.

- Replace older stencils with ones designed for finer pitch components, as lead-free pastes often have different flow characteristics.

Step 4: Training and Certification

- Train staff on IPC J-STD-001 standards for lead-free soldering techniques.

- Certify operators through IPC programs to ensure consistent quality in assembly processes.

Step 5: Documentation and Auditing

- Maintain detailed records of material sourcing, process parameters, and quality inspections.

- Conduct internal audits to identify gaps in compliance before seeking external certification.

The Lead-Free PCB Manufacturing Process: Key Considerations

Transitioning to a lead-free PCB manufacturing process requires careful planning and execution. Lead-free solders behave differently than their lead-based counterparts, often leading to challenges like poor wetting, increased thermal stress, and potential board warpage. Below are critical aspects to address during manufacturing.

1. Material Compatibility

Not all PCB materials are suited for lead-free processes due to the higher temperatures involved. For example, standard FR-4 laminates may degrade under repeated thermal cycles above 230°C. Opt for high-Tg (glass transition temperature) materials with Tg values of 170°C or higher to withstand these conditions.

2. Soldering Techniques

Lead-free solders require precise control during reflow. A typical SAC305 alloy has a melting point of 217°C, necessitating a reflow profile with a time above liquidus (TAL) of 60-90 seconds to ensure proper joint formation. Overheating, however, can damage components, so monitoring temperature uniformity across the board is crucial.

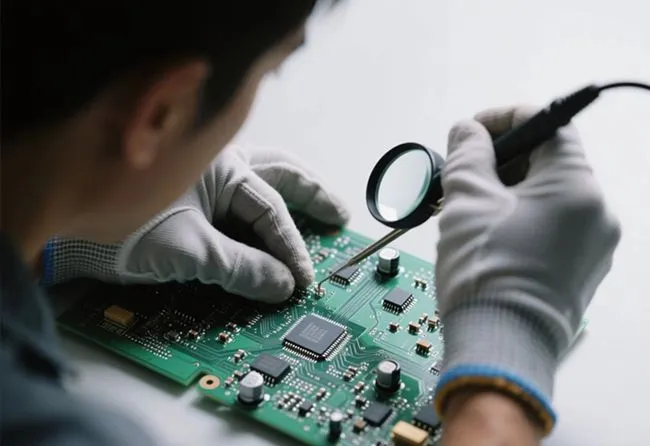

3. Inspection and Quality Control

Lead-free solder joints often appear duller and grainier than lead-based ones, which can be mistaken for defects. Use Automated Optical Inspection (AOI) systems calibrated for lead-free criteria as per IPC-A-610 standards. Additionally, employ X-ray inspection to detect hidden defects like voids in Ball Grid Array (BGA) packages, ensuring void percentages remain below 25% as recommended by IPC guidelines.

RoHS Compliance in PCB Assembly: Best Practices

Achieving RoHS compliance in PCB assembly goes beyond just using lead-free materials. It involves a holistic approach to material sourcing, process control, and documentation. Here are some best practices to ensure compliance:

- Supplier Collaboration: Partner with suppliers who provide RoHS-compliant components and maintain transparency in their supply chain.

- Labeling: Clearly mark products and packaging with RoHS compliance symbols to inform customers and regulators.

- Testing: Regularly test finished assemblies using methods like Energy Dispersive X-ray Spectroscopy (EDS) to verify the absence of restricted substances.

- Record-Keeping: Maintain records for at least five years, as required by RoHS regulations, to demonstrate compliance during audits.

Challenges in Lead-Free Assembly and How to Overcome Them

Switching to lead-free assembly isn't without its hurdles. Manufacturers often face issues like increased costs, compatibility problems, and reliability concerns. Here's how to tackle these challenges:

1. Higher Costs of Materials and Equipment

Lead-free solders and compatible components are typically 30-50% more expensive than traditional materials. To manage costs, negotiate bulk pricing with suppliers and invest in energy-efficient reflow ovens to reduce long-term operational expenses.

2. Thermal Stress on Components

The elevated temperatures of lead-free soldering can stress components, leading to failures like delamination or cracking. Mitigate this by selecting components rated for lead-free processes and using thermal profiling tools to optimize reflow conditions.

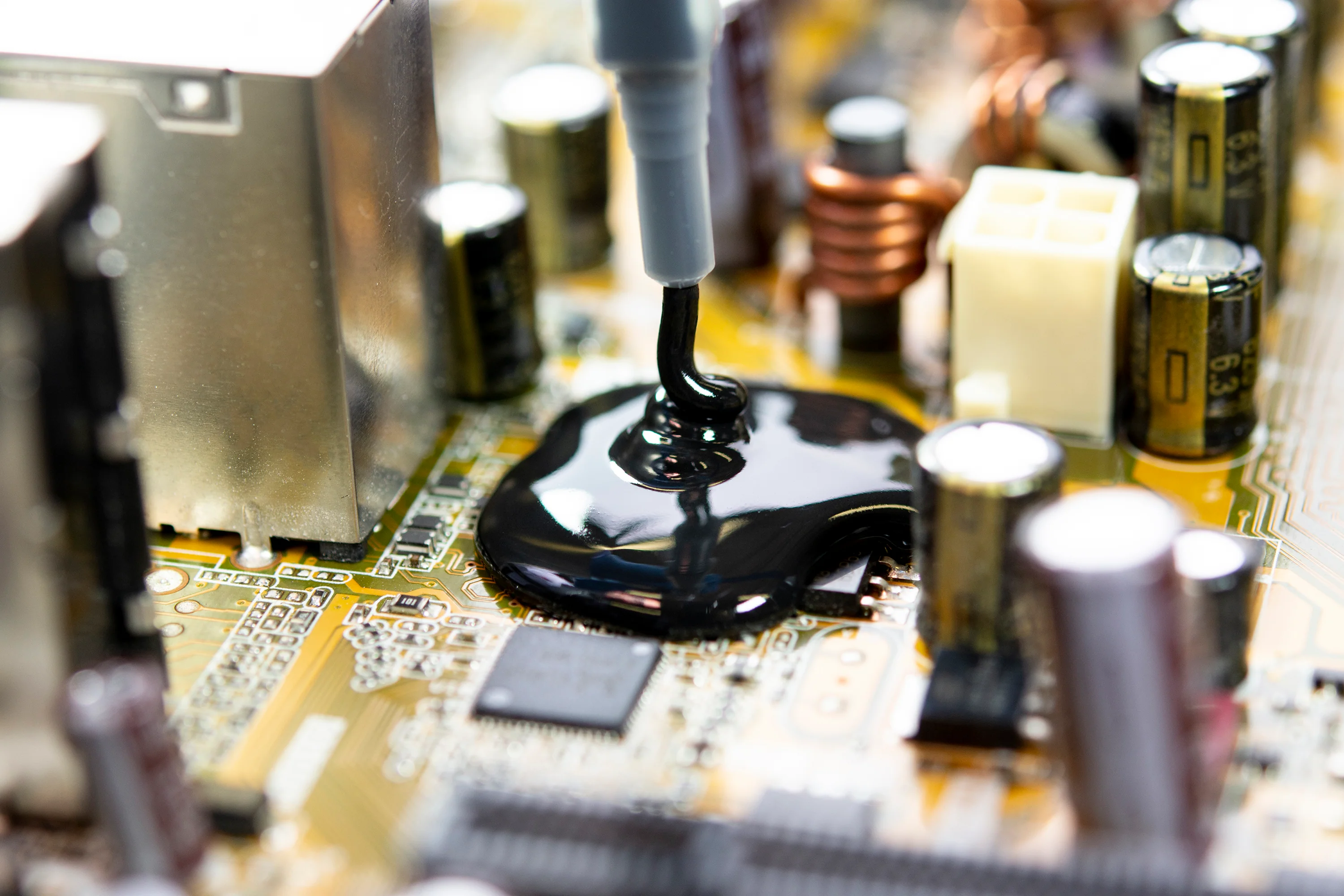

3. Reliability Concerns with Solder Joints

Lead-free solder joints are more prone to issues like tin whiskers, which can cause short circuits. Minimize risks by applying conformal coatings to protect assemblies and following IPC guidelines for joint design and inspection.

Benefits of Lead-Free Assembly Certification

While the transition to lead-free assembly requires effort, the benefits are substantial. Certification opens doors to international markets, particularly in regions with strict environmental regulations. It also enhances product reliability, as lead-free processes often result in stronger solder joints when executed correctly. Additionally, demonstrating a commitment to sustainability can strengthen customer trust and brand reputation.

Conclusion: Your Path to Lead-Free Assembly Success

Navigating lead-free assembly certification doesn't have to be overwhelming. By understanding the lead-free assembly certification requirements, following a detailed checklist, and aligning with IPC lead-free assembly standards, PCB manufacturers can achieve compliance with confidence. Embracing RoHS compliance in PCB assembly and refining the lead-free PCB manufacturing process not only ensures regulatory adherence but also positions your business as a leader in sustainable electronics production.

Start by auditing your current processes against the checklist provided, invest in training and equipment upgrades, and maintain meticulous documentation. With these steps, you'll be well on your way to certification and ready to meet the demands of a greener, more regulated industry landscape.

ALLPCB

ALLPCB