Conformal coating thickness measurement is a critical step in ensuring the protection of printed circuit boards (PCBs) from environmental hazards like moisture, dust, and thermal stress. Whether you're dealing with wet film or dry film thickness, understanding the right methods and standards can make the difference between a reliable product and a costly failure. In this comprehensive guide, we'll explore the best practices for measuring conformal coating thickness, the standards to follow, and actionable tips to achieve optimal PCB protection.

Why Conformal Coating Thickness Matters for PCB Protection

Conformal coating acts as a protective shield for PCBs, safeguarding delicate components from harsh conditions such as humidity, chemical exposure, and temperature fluctuations. However, the effectiveness of this barrier heavily depends on achieving the correct thickness. Too thin a coating may fail to provide adequate protection, leaving components vulnerable to corrosion or electrical shorts. On the other hand, a coating that is too thick can cause issues like cracking under thermal stress or interference with component functionality.

Typically, conformal coating thickness ranges from 25 to 250 micrometers (μm), depending on the application and material used. Measuring and maintaining this thickness ensures dielectric strength (often above 6000V/mil) and operational reliability. In this guide, we'll dive into the specifics of conformal coating thickness measurement methods, standards, and the differences between wet and dry film thickness to help you achieve consistent results.

What Is Conformal Coating and Why Measure Its Thickness?

Conformal coating is a thin polymeric film applied to PCBs to protect against environmental threats. It "conforms" to the board's irregular surface, creating a barrier that prevents moisture ingress, dust accumulation, and chemical corrosion. Common materials include acrylic, silicone, polyurethane, and parylene, each with unique properties suited to different environments.

Measuring the thickness of this coating is essential to ensure it performs as intended. A coating that falls outside the recommended range can compromise the board's performance. For instance, a study by industry experts suggests that a coating thickness below 25 μm may fail to provide adequate insulation, while exceeding 250 μm can lead to stress on components during thermal expansion, potentially causing cracks.

Conformal Coating Thickness Standards: A Roadmap to Reliability

Adhering to industry standards is crucial for achieving consistent and reliable results in conformal coating applications. These standards provide guidelines on acceptable thickness ranges, testing methods, and performance criteria to ensure PCBs are adequately protected.

IPC-CC-830: The Benchmark for Conformal Coating

One of the most widely recognized standards is IPC-CC-830, which outlines the qualification and performance requirements for conformal coatings. This standard categorizes coatings into eight distinct families, including acrylic and polyurethane, and specifies thickness ranges based on the type of coating and application. For example, it recommends a dry film thickness of 30-130 μm for acrylic coatings and 50-210 μm for silicone coatings to ensure optimal protection.

MIL-I-46058C: Military-Grade Specifications

For applications requiring high reliability, such as in aerospace or defense, the MIL-I-46058C standard is often referenced. Although it is no longer active for new designs, many industries still use its guidelines. It emphasizes a dry film thickness range of 25-75 μm for most coatings to balance protection and flexibility.

Following these conformal coating thickness standards ensures that your PCBs meet performance and durability expectations, especially in demanding environments. Always consult the relevant standard for your specific application to avoid costly rework or failures.

Conformal Coating Thickness Measurement Methods: Tools and Techniques

Accurate measurement of conformal coating thickness is vital to verify that it meets the required specifications. There are several methods available, each suited to different stages of the coating process (wet or dry film) and specific application needs. Below, we explore the most common conformal coating thickness measurement methods.

1. Wet Film Thickness Measurement

Measuring the conformal coating wet film thickness occurs immediately after application, before the coating cures. This method helps predict the final dry film thickness, as coatings typically shrink by 50-70% during curing, depending on the material.

Tools Used: Wet film thickness gauges, often in the form of combs or wheels, are the go-to tools. These devices have notched edges that are pressed into the wet coating. The deepest notch that picks up coating material indicates the thickness.

Process: Place the gauge on the coated surface right after application. Read the value from the notch where the coating just touches. For example, if a wet film measures 100 μm, the dry film might be around 30-50 μm after curing, based on the material's shrinkage rate.

Advantages: This method is quick, inexpensive, and allows for immediate adjustments during application to avoid over- or under-coating.

2. Dry Film Thickness Measurement

Once the coating has cured, measuring the conformal coating dry film thickness provides the final confirmation of whether the coating meets the required standards. This is the most critical measurement for ensuring long-term protection.

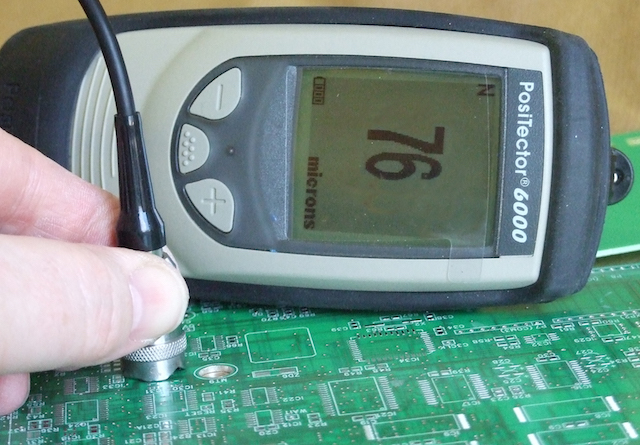

Tools Used: Non-destructive coating thickness gauges, such as eddy current or ultrasonic devices, are commonly used. These tools measure the coating thickness without damaging the PCB. For destructive testing, cross-sectional microscopy can be employed, though it’s less common due to its invasive nature.

Process: For non-destructive measurement, place the gauge probe on the coated surface. The device calculates the thickness based on changes in electrical or acoustic signals. For instance, a typical reading for a silicone coating might show 75 μm, which falls within the acceptable range per IPC standards.

Advantages: Non-destructive methods are precise and repeatable, making them ideal for quality control in high-volume production.

3. Optical and Laser-Based Measurement

For advanced applications, optical profilometers or laser-based systems can measure both wet and dry film thickness with high accuracy. These tools use light or laser beams to create a 3D map of the coating surface, providing detailed thickness data across the entire PCB.

Process: The device scans the surface, and software analyzes the data to report thickness variations. This method is particularly useful for detecting uneven coatings, which could lead to weak spots.

Advantages: High precision (down to 1 μm) and the ability to measure complex geometries make this method ideal for critical applications like medical or aerospace electronics.

Differences Between Wet and Dry Film Thickness in Conformal Coating

Understanding the distinction between conformal coating wet film thickness and dry film thickness is essential for achieving the desired protective layer. Here’s a breakdown of the key differences and why they matter.

Wet Film Thickness: Pre-Curing Measurement

Wet film thickness refers to the measurement taken immediately after the coating is applied, while it is still in a liquid state. This value is always higher than the final dry thickness due to solvent evaporation and curing shrinkage. For instance, a wet film thickness of 150 μm for an acrylic coating might result in a dry thickness of 45-60 μm, depending on the formulation.

Measuring at this stage allows for real-time adjustments. If the wet film is too thin, additional layers can be applied before curing. This proactive approach saves time and reduces the risk of rework.

Dry Film Thickness: Post-Curing Confirmation

Dry film thickness is the final measurement taken after the coating has fully cured. This value determines whether the coating meets the specified standards for protection. Most industry guidelines, like IPC-CC-830, refer to dry film thickness when defining acceptable ranges (e.g., 30-130 μm for acrylic coatings).

Ensuring the correct dry film thickness is critical for long-term reliability. A coating that measures 25 μm after curing might provide insufficient dielectric strength, risking electrical failures in high-voltage applications.

Why Both Measurements Matter

Tracking both wet and dry film thickness provides a complete picture of the coating process. Wet film measurements help control application, while dry film measurements confirm the final result. By correlating the two, you can fine-tune your process to consistently achieve the target thickness, minimizing defects and ensuring PCB protection.

Best Practices for Accurate Conformal Coating Thickness Measurement

To achieve reliable results, follow these best practices when measuring conformal coating thickness:

- Calibrate Tools Regularly: Ensure that thickness gauges and measurement devices are calibrated according to manufacturer specifications to avoid inaccurate readings.

- Measure Multiple Points: Take readings at several locations on the PCB to account for variations in coating uniformity, especially on complex board designs.

- Understand Material Shrinkage: Know the expected shrinkage rate of your coating material to predict dry film thickness from wet film measurements accurately.

- Use Appropriate Tools: Choose the right measurement method based on whether you’re assessing wet or dry film and the precision required for your application.

- Document Results: Keep detailed records of thickness measurements for quality control and traceability, especially in industries with strict compliance requirements.

Common Challenges in Conformal Coating Thickness Measurement

Despite the availability of advanced tools, measuring conformal coating thickness can present challenges. Being aware of these issues can help you mitigate them effectively.

Uneven Coating Application

Coatings applied by brushing or spraying may result in uneven thickness, especially around components with varying heights. This can lead to inconsistent measurements and weak spots. Using automated dispensing systems or dip coating methods can improve uniformity.

Complex PCB Geometries

PCBs with intricate designs or high-density components can make it difficult to access certain areas for measurement. Optical or laser-based tools are often necessary to capture accurate data in such cases.

Material Variability

Different coating materials have unique curing behaviors and shrinkage rates, which can affect the accuracy of wet-to-dry thickness predictions. Always refer to the manufacturer’s data sheet for specific guidance on each material.

How to Ensure Optimal PCB Protection with Proper Thickness

Achieving the right conformal coating thickness is the foundation of effective PCB protection. Here are actionable steps to ensure your coatings deliver the intended performance:

- Follow Standards: Adhere to guidelines like IPC-CC-830 to select the appropriate thickness range for your coating type and application.

- Monitor Application Process: Use wet film thickness measurements to control the amount of coating applied and avoid over- or under-coating.

- Verify Final Results: Confirm dry film thickness after curing to ensure compliance with specifications and long-term reliability.

- Test Performance: Conduct environmental testing, such as humidity or thermal cycling (e.g., 1000+ cycles), to validate that the coating thickness provides adequate protection under real-world conditions.

Conclusion: Mastering Conformal Coating Thickness for Reliable PCBs

Conformal coating thickness measurement is a vital aspect of PCB manufacturing, directly impacting the durability and performance of electronic devices. By understanding the differences between wet and dry film thickness, leveraging the right measurement methods, and adhering to industry standards like IPC-CC-830, you can ensure optimal protection for your PCBs. Whether you’re using simple wet film combs or advanced laser-based systems, precision and consistency are key to avoiding failures and extending product life.

At ALLPCB, we’re committed to helping you achieve the highest quality in your PCB projects. By mastering conformal coating thickness measurement methods and standards, you’ll be well-equipped to protect your boards from environmental challenges and deliver reliable, long-lasting electronics.

ALLPCB

ALLPCB