When it comes to protecting electronics in harsh environments, selecting the right potting material is critical. Whether you're dealing with extreme temperatures, chemical exposure, or mechanical stress, the choice between epoxy potting compound and silicone potting compound can make or break your project's success. So, which is better for harsh environment electronics potting? In short, epoxy offers superior chemical resistance and mechanical strength, while silicone excels in a wider temperature range and flexibility. The best choice depends on your specific application needs.

In this comprehensive guide, we’ll dive deep into a potting material comparison, focusing on epoxy potting compound chemical resistance, silicone potting compound temperature range, and other key factors. We’ll also provide a potting compound selection guide to help you make an informed decision for your harsh environment electronics projects.

Why Potting Materials Matter for Harsh Environment Electronics

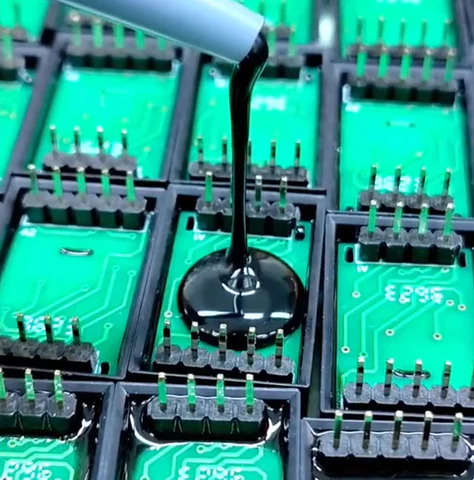

Harsh environments—think extreme heat, freezing cold, chemical spills, or constant vibration—can damage sensitive electronic components. Potting materials encapsulate these components, forming a protective barrier against moisture, dust, chemicals, and physical stress. Without proper protection, electronics can fail prematurely, leading to costly repairs or safety hazards.

Potting compounds are widely used in industries like automotive, aerospace, marine, and renewable energy, where electronics face tough conditions daily. Choosing the right material ensures reliability and longevity. Let’s explore the two most common options: epoxy and silicone, and see how they stack up for harsh environment electronics potting.

Epoxy Potting Compound: Strength and Chemical Resistance

Epoxy potting compounds are thermosetting resins that harden into a solid, rigid material after curing. They are known for their exceptional mechanical strength and durability, making them a popular choice for harsh environment electronics potting.

Key Benefits of Epoxy Potting Compounds

- Epoxy Potting Compound Chemical Resistance: Epoxy materials resist a wide range of chemicals, including acids, bases, solvents, and fuels. This makes them ideal for applications in industrial settings or automotive under-hood environments where exposure to harsh substances is common. For example, epoxy can withstand prolonged contact with oils and hydraulic fluids without degrading.

- Mechanical Strength: Once cured, epoxy forms a hard, durable shell that protects against impact and vibration. It’s often used in applications where electronics are subject to physical stress, such as in heavy machinery or military equipment.

- Thermal Conductivity: Many epoxy formulations offer good thermal conductivity, helping to dissipate heat from components. Some epoxies can handle continuous operating temperatures up to 150°C (302°F), though this varies by formulation.

- Moisture Resistance: Epoxy provides a strong barrier against water and humidity, preventing corrosion of delicate components.

Limitations of Epoxy Potting Compounds

- Limited Temperature Range: While epoxy performs well at moderate temperatures, it can become brittle or crack under extreme cold (below -40°C or -40°F) or very high heat (above 150°C or 302°F in many cases).

- Rigidity: The hard nature of epoxy means it offers little flexibility. In applications with thermal expansion or frequent vibration, this rigidity can lead to stress on components.

- Difficult Rework: Once cured, epoxy is nearly impossible to remove without damaging the electronics, making repairs or modifications challenging.

Silicone Potting Compound: Flexibility and Temperature Range

Silicone potting compounds are elastomeric materials that remain flexible after curing. They are widely valued for their adaptability to extreme temperatures and softer, more forgiving nature compared to epoxy.

Key Benefits of Silicone Potting Compounds

- Silicone Potting Compound Temperature Range: Silicone shines in extreme temperatures, often operating effectively from -60°C (-76°F) to 200°C (392°F) or higher in specialized formulations. This makes it a top choice for aerospace, automotive, and outdoor applications where temperature fluctuations are common.

- Flexibility: Unlike epoxy, silicone remains soft and pliable after curing. This flexibility absorbs shocks and vibrations, reducing stress on components during thermal expansion or mechanical movement.

- Waterproofing: Silicone offers excellent resistance to moisture and can even be used in underwater applications, such as marine electronics.

- Ease of Rework: Silicone is easier to remove than epoxy, allowing for repairs or component replacement without extensive damage.

Limitations of Silicone Potting Compounds

- Lower Chemical Resistance: Silicone is less resistant to harsh chemicals compared to epoxy. It can degrade when exposed to certain solvents, oils, or fuels, limiting its use in chemically aggressive environments.

- Mechanical Strength: Silicone’s flexibility comes at the cost of lower tensile strength. It may not provide adequate protection against severe physical impacts.

- Thermal Conductivity: Silicone generally has lower thermal conductivity than epoxy, which may lead to heat buildup in high-power electronics unless enhanced formulations are used.

Potting Material Comparison Chart: Epoxy vs. Silicone

To make your decision easier, we’ve created a potting material comparison chart that highlights the key differences between epoxy and silicone potting compounds for harsh environment electronics potting. Use this as a quick reference in your potting compound selection guide.

| Property | Epoxy Potting Compound | Silicone Potting Compound |

|---|---|---|

| Chemical Resistance | Excellent (resists acids, bases, solvents) | Moderate (vulnerable to some solvents and oils) |

| Temperature Range | -40°C to 150°C (-40°F to 302°F) | -60°C to 200°C (-76°F to 392°F) |

| Mechanical Strength | High (rigid, impact-resistant) | Low (flexible, less impact protection) |

| Flexibility | Low (brittle under stress) | High (absorbs vibration and thermal expansion) |

| Moisture Resistance | Excellent | Excellent (suitable for underwater use) |

| Thermal Conductivity | Moderate to High (varies by formulation) | Low to Moderate |

| Ease of Rework | Difficult (permanent once cured) | Easier (can be removed) |

Potting Compound Selection Guide for Harsh Environment Electronics

Choosing the right potting material for harsh environment electronics potting involves evaluating your specific application requirements. Here’s a step-by-step potting compound selection guide to help you decide between epoxy and silicone.

1. Assess Environmental Conditions

- Chemical Exposure: If your electronics will be exposed to harsh chemicals like fuels or solvents, prioritize epoxy potting compound chemical resistance. For example, in automotive under-hood applications, epoxy is often the better choice.

- Temperature Extremes: For applications with wide temperature swings or extreme cold/heat, consider the silicone potting compound temperature range. Silicone is ideal for outdoor sensors or aerospace components operating at -50°C or 180°C.

- Moisture Levels: Both materials offer excellent moisture resistance, but silicone may be preferred for fully submerged applications due to its flexibility and sealing properties.

2. Evaluate Mechanical Stress

- Vibration and Shock: If your electronics are in a high-vibration environment, such as in industrial machinery, silicone’s flexibility can absorb shocks better than rigid epoxy.

- Physical Impact: For applications where impact resistance is critical, epoxy’s hardness provides superior protection against drops or collisions.

3. Consider Thermal Management

- Heat Dissipation: High-power electronics generating significant heat may benefit from epoxy formulations with enhanced thermal conductivity (up to 1.5 W/m·K in some cases) to prevent overheating.

- Temperature Cycling: If your application involves frequent thermal cycling, silicone’s ability to handle expansion and contraction without cracking makes it a safer bet.

4. Plan for Maintenance and Rework

- If you anticipate needing to access components for repairs or upgrades, silicone’s reworkability is a significant advantage over epoxy, which is often permanent.

Real-World Applications: Epoxy and Silicone in Action

To illustrate how these materials perform, let’s look at two common scenarios for harsh environment electronics potting.

Automotive Electronics

In automotive applications, electronics are exposed to engine heat, oil, and vibration. An epoxy potting compound with high chemical resistance and thermal conductivity (around 1.2 W/m·K) can protect control units from fluid leaks and temperatures up to 130°C (266°F). Its rigidity also shields against road shocks.

Outdoor Sensors for Renewable Energy

For sensors in solar or wind energy systems, silicone potting compounds are often preferred due to their wide temperature range (-50°C to 180°C or -58°F to 356°F). Their flexibility accommodates thermal expansion during day-night cycles, and their moisture resistance protects against rain and humidity.

Conclusion: Making the Right Choice for Harsh Environment Electronics Potting

Selecting between epoxy and silicone potting compounds for harsh environment electronics comes down to understanding your specific needs. If your priority is epoxy potting compound chemical resistance and mechanical strength, epoxy is likely the better choice. If you need a wide silicone potting compound temperature range and flexibility, silicone stands out as the optimal material.

Use the potting material comparison chart and potting compound selection guide provided in this article to weigh the pros and cons based on your application’s environmental, mechanical, and thermal requirements. By choosing the right potting material, you can ensure the reliability and longevity of your electronics, even in the toughest conditions.

At ALLPCB, we’re committed to helping you navigate the complexities of electronics manufacturing and protection. Whether you’re designing for automotive, industrial, or outdoor applications, our expertise can guide you to the best solutions for your projects.

ALLPCB

ALLPCB