Choosing the right solder paste for rigid board assembly can make or break your PCB project. Whether you're an engineer working on surface-mount technology (SMT) or a manufacturer aiming for high reliability, understanding solder paste types, solder paste reflow profiles, and strategies for optimizing solder joint reliability is essential. This guide also explores no-clean solder paste and lead-free solder paste alternatives to help you make informed decisions for your next assembly. Let’s dive into the details to ensure your rigid board assemblies are both efficient and durable.

Why Solder Paste Selection Matters for Rigid Board Assembly

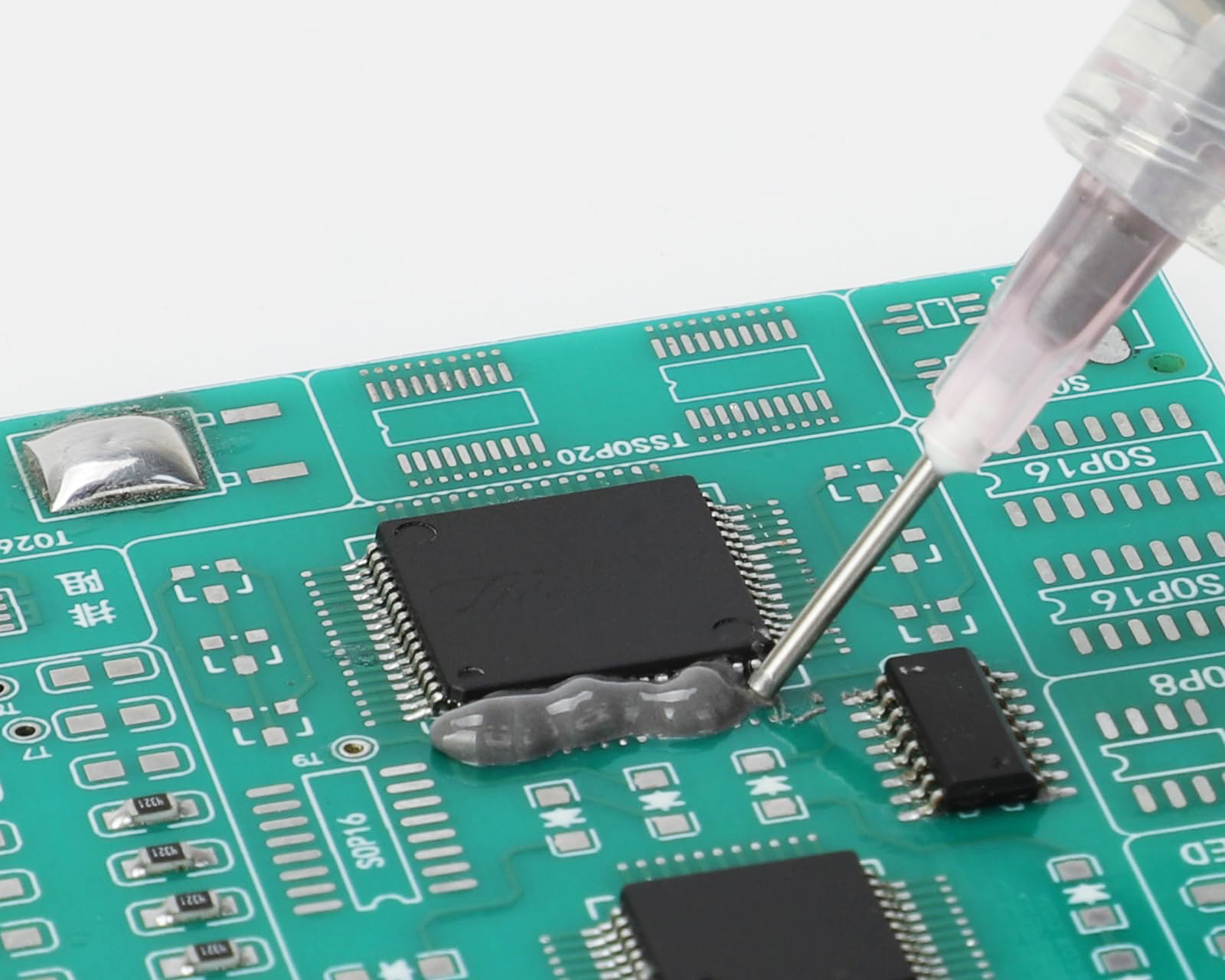

Solder paste is the foundation of modern PCB assembly, especially for rigid boards using SMT. It serves as both an adhesive to hold components in place before reflow soldering and as the material that creates strong electrical and mechanical bonds. A poor choice in solder paste can lead to weak joints, defects like tombstoning, or voids, all of which can compromise the reliability of your circuit. For rigid board assemblies, where durability and performance under stress are critical, selecting the right paste is non-negotiable.

In this blog, we’ll break down everything you need to know about solder paste selection, from understanding different types to optimizing reflow profiles and ensuring joint reliability. By the end, you’ll have actionable insights to improve your assembly process.

Understanding Solder Paste Types for Rigid Board Assembly

Solder paste is a mix of tiny metal alloy particles and flux, a chemical agent that cleans surfaces and prevents oxidation during soldering. The type of solder paste you choose directly impacts the quality of your assembly. Let’s explore the main categories and how they apply to rigid boards.

1. Leaded vs. Lead-Free Solder Paste

Traditionally, solder paste contained lead due to its low melting point and excellent wetting properties. However, environmental regulations like RoHS (Restriction of Hazardous Substances) have pushed the industry toward lead-free solder paste alternatives. Lead-free pastes, often made with alloys like SAC305 (tin-silver-copper), have higher melting points (around 217-221°C compared to 183°C for leaded solder). This means they require precise solder paste reflow profiles to avoid thermal damage to components on rigid boards.

For rigid board assemblies, lead-free options are often preferred due to compliance needs, though they can be more prone to defects like voids if not handled correctly. If your project allows leaded solder, it may offer easier processing, but always check regulatory requirements first.

2. Particle Size Classifications (Type 3, Type 4, Type 5)

Solder paste is classified by particle size, which affects how it’s applied and its suitability for fine-pitch components. The most common types are:

- Type 3 (25-45 μm): Ideal for standard SMT components with larger pitches. It’s widely used for rigid boards with less complex designs.

- Type 4 (20-38 μm): Suited for finer pitches and smaller components, offering better printability for dense rigid board layouts.

- Type 5 (15-25 μm): Best for ultra-fine pitch applications, like micro-BGA or 0201 components, often seen in high-density rigid assemblies.

Choosing the right particle size ensures precise deposition through stencils, reducing defects like bridging or insufficient solder volume on rigid boards.

3. Flux Types in Solder Paste

Flux in solder paste removes oxides and ensures good wetting. There are three main flux categories:

- Rosin-Based: Offers strong adhesion and reliability but often requires cleaning after soldering.

- Water-Soluble: Easy to clean with water, though residues can be corrosive if not fully removed.

- No-Clean: Leaves minimal residue that doesn’t require post-soldering cleaning, making no-clean solder paste a popular choice for rigid board assembly where efficiency is key.

For rigid boards, no-clean options are often favored to streamline production, provided the residue doesn’t interfere with testing or performance.

Key Factors in Solder Paste Selection for Rigid Boards

Beyond type, several factors influence which solder paste is best for your rigid board assembly. Let’s look at the most critical considerations.

1. Compatibility with Components and Board Materials

Rigid boards often use materials like FR-4, which can withstand higher temperatures. However, the components mounted on them may have lower thermal limits. Ensure the solder paste’s melting point and reflow profile align with both the board and component specifications to prevent damage. For instance, lead-free SAC305 paste requires peak temperatures of around 240-260°C, which may stress sensitive parts if not managed properly.

2. Application Method and Stencil Design

Solder paste is typically applied via stencil printing in SMT assembly. The stencil aperture size and thickness must match the paste’s particle size and viscosity. For rigid boards with mixed component sizes, a Type 4 paste with a stencil thickness of 0.1-0.15 mm often provides a good balance for consistent deposition.

3. Storage and Shelf Life

Solder paste is sensitive to temperature and humidity. Store it at 2-10°C to maintain its properties, and always check the shelf life (typically 6-12 months when refrigerated). For rigid board assembly lines with high throughput, proper storage prevents paste degradation, ensuring consistent results.

Optimizing Solder Paste Reflow Profiles for Rigid Board Assembly

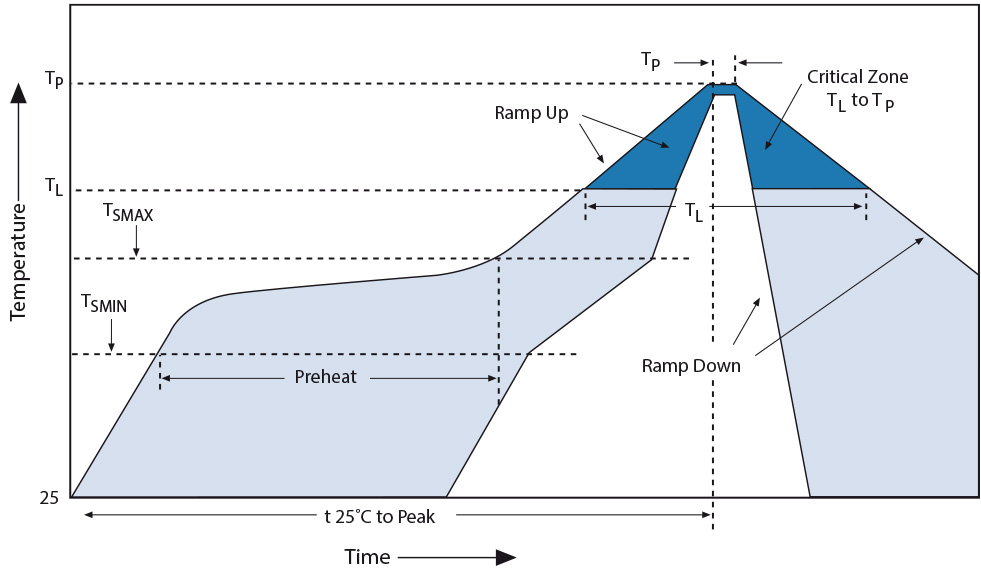

The reflow soldering process is where solder paste transforms into solid joints. A well-designed solder paste reflow profile is crucial for optimizing solder joint reliability on rigid boards. A typical reflow profile has four stages:

1. Preheat Stage

This stage (typically 1-3°C per second up to 150-180°C) activates the flux to clean surfaces and evaporates solvents. For rigid boards, avoid rapid heating to prevent thermal shock to the board material.

2. Soak Stage

During soak (150-180°C for 60-120 seconds), the board and components stabilize in temperature. This minimizes thermal gradients, which is especially important for rigid boards with dense layouts to prevent defects like tombstoning.

3. Reflow Stage

The peak temperature (220-260°C for lead-free paste) melts the solder particles to form joints. Keep the time above liquidus (TAL) between 30-90 seconds to ensure proper wetting without overheating. For rigid boards, precise control here prevents voids or weak joints.

4. Cooling Stage

Cooling (2-4°C per second) solidifies the solder. Too fast a cooling rate can cause thermal stress in rigid boards, leading to cracks, while too slow can result in grainy solder joints.

Adjusting these stages based on your solder paste type and board design is key. Many modern reflow ovens allow programming custom profiles, so test and tweak settings to match your specific assembly needs.

Strategies for Optimizing Solder Joint Reliability

Reliable solder joints are the backbone of any rigid board assembly. Here are proven strategies to ensure strong, durable connections.

1. Minimize Voids in Solder Joints

Voids occur when gas is trapped during reflow, weakening joints. Studies show voids can reduce joint strength by up to 30%. Use a solder paste with low voiding properties and optimize the reflow profile to allow gas escape during the soak stage. For rigid boards in high-stress applications, aim for void levels below 10% in critical areas like BGA joints.

2. Prevent Common Defects

Defects like bridging (solder connecting adjacent pads) or tombstoning (components standing on end) often stem from poor paste application or reflow settings. Ensure stencil alignment and paste volume are correct, and maintain a balanced reflow profile to avoid uneven heating on rigid boards.

3. Test and Inspect Joints

After assembly, use X-ray inspection for hidden joints (like under BGAs) and automated optical inspection (AOI) for visible defects. For rigid boards in critical applications, shear testing can confirm joint strength, targeting values above 20N for typical SMT components.

Advantages of No-Clean Solder Paste for Rigid Boards

No-clean solder paste has become a go-to choice for many rigid board assemblies due to its efficiency. Unlike traditional pastes, it leaves minimal residue that doesn’t need cleaning, saving time and cost in production. This is especially beneficial for high-volume rigid board projects where cleaning steps can slow down the process.

However, ensure the residue won’t affect downstream processes like conformal coating or in-circuit testing. For most rigid board applications, no-clean paste offers a reliable balance of performance and convenience.

Exploring Lead-Free Solder Paste Alternatives

With the shift to lead-free solder paste alternatives, several alloy compositions have emerged as viable options for rigid board assembly. Beyond the standard SAC305, consider:

- SAC387 (Tin-Silver-Copper): Offers similar properties to SAC305 but with slightly better thermal fatigue resistance, ideal for rigid boards in harsh environments.

- SnBiAg (Tin-Bismuth-Silver): A low-temperature alternative with a melting point around 138°C, suitable for heat-sensitive components on rigid boards.

- Innolot: A specialized alloy with additives to enhance creep resistance, often used in automotive rigid board applications.

Each alternative has trade-offs in cost, melting point, and mechanical properties, so match the alloy to your project’s thermal and reliability needs.

Practical Tips for Solder Paste Handling in Rigid Board Assembly

To wrap up, here are some hands-on tips to ensure success with solder paste in your rigid board projects:

- Always warm solder paste to room temperature (takes about 4-6 hours) before use to avoid condensation and ensure proper viscosity.

- Use a stencil with a release coating to prevent paste sticking, ensuring clean deposits on rigid boards.

- Monitor reflow oven conditions daily, as variations in temperature or conveyor speed can affect joint quality.

- Track paste usage with a first-in, first-out (FIFO) system to avoid expired materials in your assembly line.

Conclusion: Mastering Solder Paste Selection for Reliable Rigid Boards

Selecting the right solder paste for rigid board assembly is a critical step in achieving high-quality, reliable PCBs. By understanding solder paste types, fine-tuning solder paste reflow profiles, and focusing on optimizing solder joint reliability, you can minimize defects and ensure long-term performance. Options like no-clean solder paste and lead-free solder paste alternatives offer flexibility to meet both production and regulatory demands.

Armed with the insights from this guide, you’re ready to make informed choices for your next rigid board project. Focus on compatibility, test your processes, and keep refining your approach for the best results in every assembly.

ALLPCB

ALLPCB