If you're an engineer looking to protect printed circuit boards (PCBs) from harsh environments, selecting the right conformal coating material is critical. This guide will help you navigate the complex world of conformal coating material selection by providing a detailed comparison of types like acrylic, silicone, polyurethane, epoxy, and parylene coatings. We'll break down their properties, applications, advantages, and limitations to ensure you make an informed decision for your project.

In the following sections, we'll dive deep into each type of conformal coating, explore key factors for selection, and offer practical insights to help you safeguard your electronic assemblies. Whether you're working in aerospace, automotive, or consumer electronics, this comprehensive guide will equip you with the knowledge to choose the best coating for your needs.

What Is a Conformal Coating and Why Does It Matter?

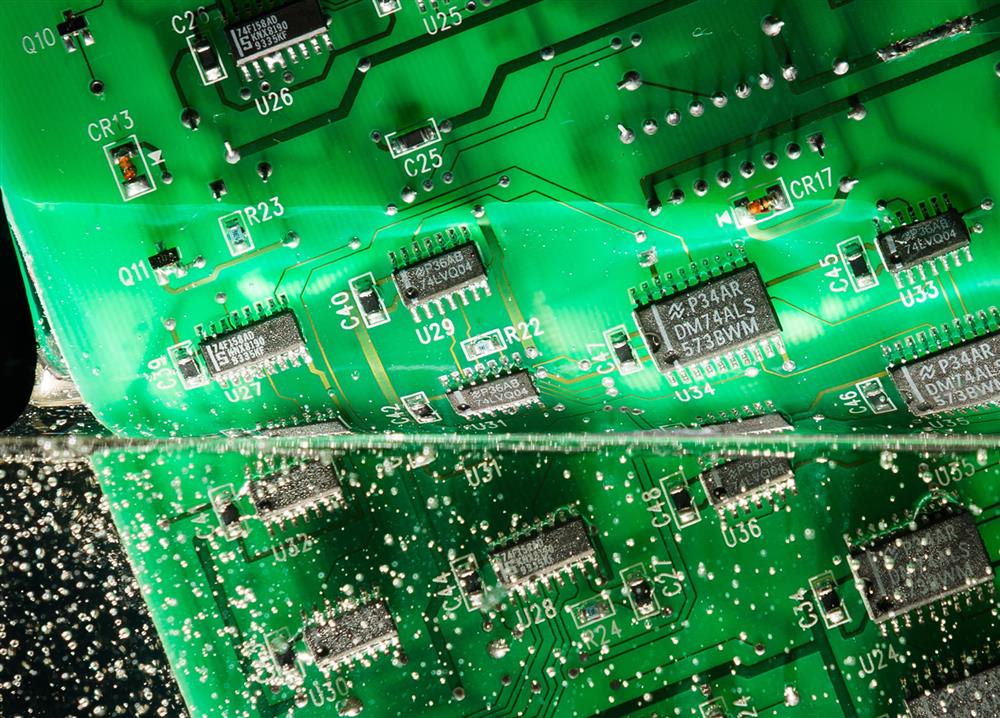

Conformal coatings are thin protective layers applied to PCBs and electronic assemblies to shield them from environmental hazards such as moisture, dust, chemicals, and temperature extremes. These coatings "conform" to the shape of the board, providing a barrier that enhances reliability and longevity. Without proper protection, electronic components can suffer from corrosion, short circuits, or mechanical damage, leading to costly failures.

For engineers, choosing the right conformal coating material is not just about protection—it's about ensuring performance under specific conditions. Factors like dielectric strength, thermal resistance, and ease of application play a huge role in the decision-making process. With various types available, understanding their unique properties is the first step in making an informed choice.

Key Factors in Conformal Coating Material Selection

Before diving into the specific types, let's look at the critical factors that influence the selection of a conformal coating material. These considerations will help you narrow down your options based on your project's requirements.

- Environmental Conditions: Will the PCB be exposed to high humidity, extreme temperatures, or corrosive chemicals? Different coatings excel in different environments.

- Dielectric Properties: Coatings must provide insulation to prevent electrical shorts. For instance, a coating with a dielectric strength of 500-1000 V/mil is often required for high-voltage applications.

- Thermal Resistance: If the PCB operates in temperatures ranging from -40°C to 150°C, the coating must withstand thermal cycling without cracking or degrading.

- Application Method: Some coatings are easier to apply via brush or spray, while others require specialized equipment like vapor deposition.

- Repairability: Can the coating be removed or reworked if repairs are needed? This is crucial for long-term maintenance.

- Cost and Availability: Budget constraints and material availability can also impact your decision.

With these factors in mind, let’s explore the most common types of conformal coatings and compare their properties to help you make the right choice.

Conformal Coating Types Comparison: Breaking Down the Options

Each conformal coating material has unique strengths and weaknesses. Below, we’ll compare acrylic, silicone, polyurethane, epoxy, and parylene coatings to give you a clear understanding of their applications.

1. Acrylic Conformal Coating

Acrylic conformal coatings are among the most widely used due to their ease of application and cost-effectiveness. These coatings are typically solvent-based and can be applied via brush, spray, or dip methods.

- Advantages:

- Excellent moisture resistance, ideal for humid environments.

- Dielectric strength of approximately 1000 V/mil, suitable for many standard applications.

- Easy to rework or remove using solvents, making repairs straightforward.

- Cost-effective for large-scale production.

- Limitations:

- Limited resistance to harsh chemicals and high temperatures (typically up to 120°C).

- Not ideal for applications requiring high mechanical strength.

- Best Applications: Consumer electronics, indoor devices, and low-cost projects where extreme conditions are not a concern.

2. Silicone Conformal Coating

Silicone conformal coatings are known for their flexibility and thermal stability, making them a popular choice for applications involving temperature fluctuations.

- Advantages:

- Exceptional thermal resistance, operating effectively from -50°C to 200°C.

- High flexibility prevents cracking during thermal cycling or mechanical stress.

- Good resistance to moisture and mild chemicals.

- Limitations:

- Lower abrasion resistance compared to other coatings.

- Difficult to rework or remove due to its chemical inertness.

- Dielectric strength (around 500-800 V/mil) may not suffice for high-voltage needs.

- Best Applications: Automotive electronics, outdoor equipment, and devices exposed to wide temperature ranges.

3. Polyurethane Conformal Coating

Polyurethane coatings offer a balance between durability and environmental protection. They are often used in applications requiring robust chemical resistance.

- Advantages:

- Superior resistance to chemicals, solvents, and abrasion.

- Good dielectric properties, with strengths around 900-1200 V/mil.

- Effective moisture barrier for humid conditions.

- Limitations:

- Limited flexibility, which can lead to cracking under mechanical stress.

- Challenging to remove for repairs, often requiring specialized solvents.

- Thermal resistance is moderate, typically up to 130°C.

- Best Applications: Industrial equipment, marine environments, and devices exposed to harsh chemicals.

4. Epoxy Conformal Coating

Epoxy coatings are two-part systems that form a hard, durable layer once cured. They are ideal for extreme conditions where maximum protection is needed.

- Advantages:

- Excellent mechanical strength and abrasion resistance.

- High dielectric strength, often exceeding 1500 V/mil, perfect for high-voltage applications.

- Strong resistance to chemicals and moisture.

- Limitations:

- Rigid nature can lead to cracking under thermal expansion or vibration.

- Very difficult to rework or remove, often requiring mechanical methods.

- Application can be complex, requiring precise mixing and curing.

- Best Applications: Aerospace components, military hardware, and environments with severe mechanical and chemical stress.

5. Parylene Conformal Coating

Parylene coatings are unique due to their vapor deposition application process, which results in an ultra-thin, pinhole-free layer. They are often considered the gold standard for high-performance applications.

- Advantages:

- Uniform coverage, even on complex geometries, with thicknesses as low as 0.5 microns.

- Outstanding dielectric strength, often around 5000 V/mil, due to its thin yet effective layer.

- Excellent resistance to moisture, chemicals, and temperatures up to 150°C.

- Limitations:

- High cost and specialized equipment required for application.

- Difficult to repair or remove without damaging the PCB.

- Not suitable for applications requiring thick coatings for mechanical protection.

- Best Applications: Medical devices, high-reliability electronics, and aerospace systems where precision and performance are critical.

Conformal Coating Material Selection Guide: Making the Right Choice

Now that we've compared the major types of conformal coatings, how do you decide which one is best for your project? Use this step-by-step guide to align your choice with your specific needs.

- Assess Environmental Demands: Identify the primary threats to your PCB, such as humidity, temperature extremes, or chemical exposure. For high humidity, acrylic or silicone might suffice, while harsh chemicals call for polyurethane or epoxy.

- Evaluate Electrical Requirements: Check the dielectric strength needed for your application. High-voltage systems may require epoxy or parylene for their superior insulation properties.

- Consider Application and Repair Needs: If ease of application and rework is important, acrylic coatings are often the best bet. For permanent protection with no rework expected, epoxy or parylene may be ideal.

- Factor in Cost Constraints: Balance performance with budget. Acrylic and silicone coatings are more affordable, while parylene comes at a premium due to its specialized application.

- Test Under Real Conditions: If possible, prototype with your chosen coating and test it under simulated operating conditions to confirm its performance.

Practical Tips for Applying Conformal Coatings

Selecting the right material is only half the battle—proper application is just as important. Here are some actionable tips to ensure optimal results:

- Surface Preparation: Clean the PCB thoroughly to remove contaminants like dust or oils. Even a small residue can prevent proper adhesion, reducing the coating's effectiveness.

- Masking Sensitive Areas: Use masking materials to protect connectors or components that should not be coated. This prevents interference with functionality.

- Control Thickness: Apply the coating in thin, even layers to avoid pooling or uneven coverage. For example, acrylic coatings are typically applied at 25-75 microns for optimal protection.

- Curing Conditions: Follow manufacturer guidelines for curing times and temperatures. Improper curing can lead to reduced performance or adhesion issues.

- Safety Precautions: Use proper ventilation and protective gear, especially when working with solvent-based coatings like acrylic or polyurethane.

Conclusion: Empowering Engineers with the Right Knowledge

Choosing the right conformal coating material is a pivotal decision that directly impacts the reliability and performance of your electronic assemblies. By understanding the strengths and limitations of acrylic, silicone, polyurethane, epoxy, and parylene conformal coatings, you can make an informed choice tailored to your project's needs. Whether you're prioritizing cost, environmental resistance, or dielectric strength, this guide offers the insights you need to protect your PCBs effectively.

Remember to consider environmental conditions, electrical requirements, and application constraints as you navigate the conformal coating material selection process. With the right coating, you can extend the lifespan of your electronics and ensure they perform flawlessly, even in the harshest conditions. Trust in this comprehensive guide to help you safeguard your designs with confidence.

ALLPCB

ALLPCB