In the world of electronics manufacturing, SMT pastes play a critical role in ensuring high-quality assembly of printed circuit boards (PCBs). If you're searching for information on SMT pastes, SMT assembly, lead-free options, or solder paste inspection (SPI), you've come to the right place. This blog post dives deep into the essentials of SMT pastes, their importance in surface mount technology (SMT) assembly, the shift to lead-free alternatives, and the significance of SPI techniques in maintaining quality. Let's explore these topics in detail to help you understand and optimize your electronics production processes.

What Are SMT Pastes and Why Are They Important?

SMT pastes, commonly known as solder pastes, are a mixture of tiny solder particles, flux, and other additives used in surface mount technology assembly. These pastes act as a bonding material to attach electronic components to PCBs during the soldering process. The paste is applied to specific areas of the board using a stencil, and then components are placed on top. When heated in a reflow oven, the paste melts, creating a strong electrical and mechanical connection between the components and the board.

The importance of SMT pastes cannot be overstated. They directly impact the reliability and performance of electronic devices. A high-quality solder paste ensures proper wetting and adhesion, reducing defects like solder bridges or insufficient joints. With the electronics industry moving toward smaller, more complex designs, the precision and consistency of SMT pastes have become even more vital.

Key Components of SMT Pastes

SMT pastes are typically composed of two main elements:

- Solder Alloy Particles: These are microscopic metal particles, often made of tin, silver, or copper alloys, that melt during reflow to form the solder joint. The particle size, usually between 20-38 micrometers for fine-pitch applications, affects printability and joint quality.

- Flux: This chemical component cleans the surfaces of the PCB and components by removing oxides, ensuring better adhesion. Flux also prevents oxidation during heating and influences the paste's shelf life and storage requirements.

SMT Assembly: The Backbone of Modern Electronics

SMT assembly is the process of mounting electronic components directly onto the surface of a PCB, as opposed to through-hole technology where components are inserted into drilled holes. This method allows for smaller, lighter, and more densely packed boards, making it ideal for modern devices like smartphones, laptops, and IoT gadgets.

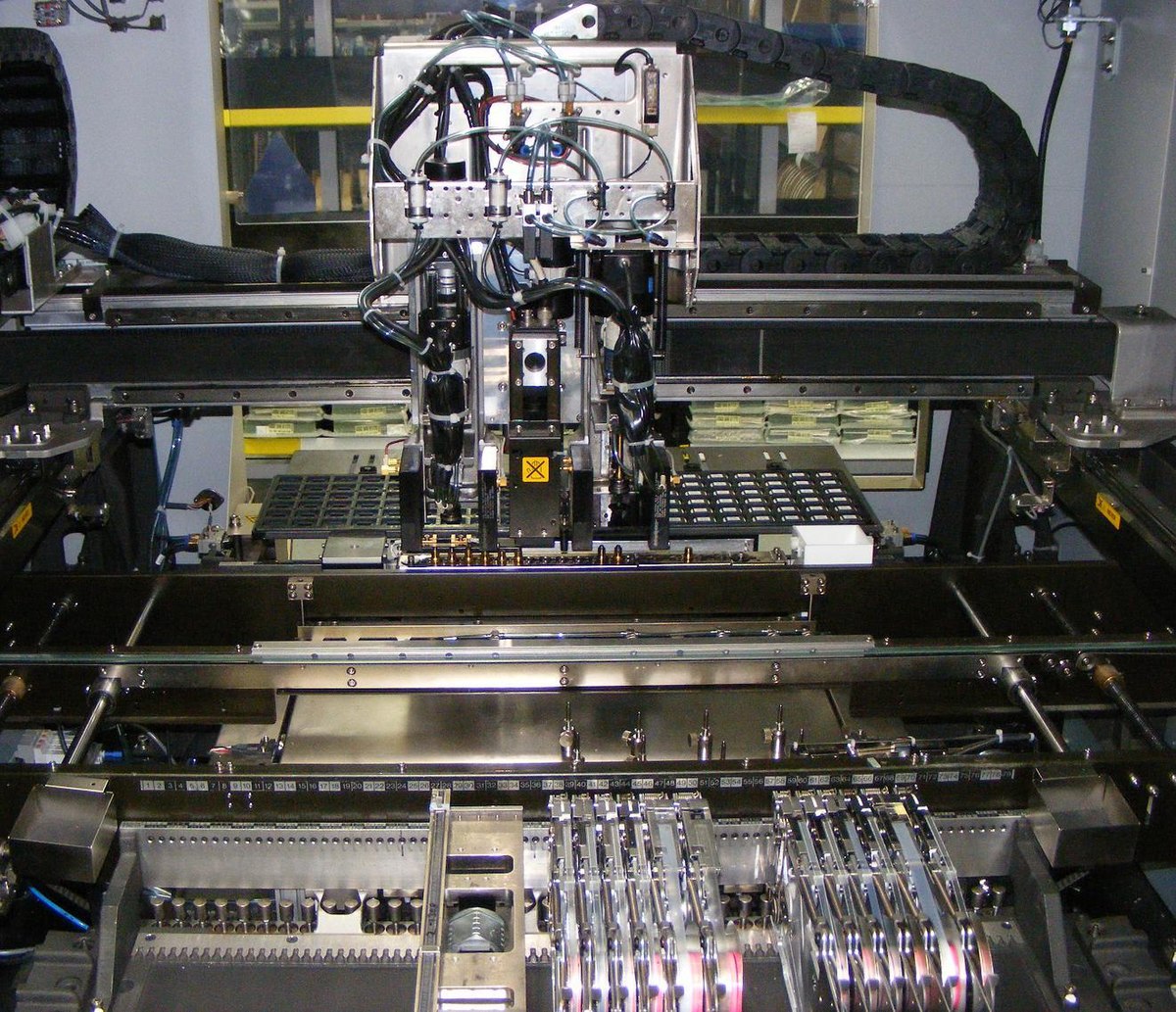

In SMT assembly, solder paste is applied using a stencil printer, followed by component placement with pick-and-place machines. The board then goes through a reflow oven, where the paste melts and solidifies to create permanent connections. The precision of this process is critical, as even a slight misalignment or inconsistent paste application can lead to defects such as tombstoning (components standing upright) or cold solder joints.

Statistics highlight the dominance of SMT in electronics manufacturing. Over 90% of PCBs produced today use surface mount technology due to its efficiency and ability to handle high-density designs. As devices continue to shrink, the demand for reliable SMT assembly processes grows, placing greater emphasis on the quality of SMT pastes used.

Challenges in SMT Assembly

While SMT assembly offers numerous advantages, it comes with challenges:

- Miniaturization: Components as small as 01005 (0.4mm x 0.2mm) require precise paste application to avoid defects.

- Thermal Stress: Uneven heating during reflow can cause components to shift or crack, especially with dense boards.

- Paste Consistency: Variations in paste viscosity or composition can lead to inconsistent printing, affecting yield rates.

The Shift to Lead-Free SMT Pastes

Historically, solder pastes were made with lead-based alloys like 63Sn/37Pb due to their low melting point (around 183°C) and excellent reliability. However, environmental and health concerns led to global regulations like the Restriction of Hazardous Substances (RoHS) directive, pushing the industry toward lead-free alternatives since the early 2000s.

Lead-free SMT pastes, often based on alloys like SAC305 (96.5% tin, 3% silver, 0.5% copper), have become the standard. These alloys have a higher melting point (around 217-220°C), requiring adjustments in reflow profiles and equipment. While lead-free pastes are safer for the environment, they present challenges such as increased risk of tin whisker growth and higher costs due to the inclusion of silver.

Benefits and Drawbacks of Lead-Free SMT Pastes

Benefits:

- Compliance with environmental regulations like RoHS and REACH.

- Reduced health risks for workers and end-users.

- Improved thermal fatigue resistance in some alloys, beneficial for high-temperature applications.

Drawbacks:

- Higher reflow temperatures can stress components and boards.

- Increased material costs, with silver-based alloys being more expensive than traditional leaded solder.

- Potential for defects like voiding if not processed correctly.

Despite these challenges, the transition to lead-free SMT pastes is a necessary step for sustainable electronics manufacturing. Manufacturers must carefully select pastes and optimize their processes to balance performance and compliance.

Solder Paste Inspection (SPI): Ensuring Quality in SMT Assembly

Solder paste inspection, or SPI, is a critical quality control step in SMT assembly. It involves using specialized machines to check the accuracy of solder paste application before components are placed and reflowed. SPI systems measure the volume, height, and alignment of paste deposits, identifying issues like insufficient paste, bridging, or misalignment early in the process.

Modern SPI techniques often use 3D imaging technology to provide detailed analysis. These systems can detect defects with high precision, ensuring that paste deposits meet industry standards, such as those set by the Institute of Printed Circuits (IPC). For example, IPC-A-610 standards specify acceptable solder paste volume ranges to prevent defects like insufficient wetting or solder balls.

Why SPI Matters

Implementing SPI in the production line offers several advantages:

- Defect Prevention: Catching issues early reduces the need for costly rework or scrap. Studies show that up to 70% of SMT defects originate from poor solder paste application.

- Improved Yield: Consistent paste application boosts first-pass yield rates, saving time and resources.

- Data for Optimization: SPI machines provide feedback that can be used to fine-tune stencil design, printer settings, and paste formulations.

As noted in recent industry discussions, integrating advanced SPI systems can significantly enhance end-product reliability, especially for high-density boards used in automotive or medical applications.

Common SPI Techniques

SPI technology has evolved to meet the demands of modern SMT assembly:

- 2D Inspection: Uses cameras to check paste alignment and coverage. While cost-effective, it lacks depth information.

- 3D Inspection: Employs laser or structured light to measure paste volume and height, offering greater accuracy for fine-pitch components.

- Automated Feedback Loops: Advanced SPI systems communicate with stencil printers to adjust settings in real-time, minimizing errors.

Choosing the Right SMT Paste for Your Application

Selecting the appropriate SMT paste is crucial for achieving reliable results in assembly. Here are key factors to consider:

- Alloy Type: Decide between leaded or lead-free based on regulatory requirements and application needs. SAC305 is a popular choice for lead-free assembly.

- Particle Size: Smaller particles (Type 4 or 5, ranging from 15-25 micrometers) are better for fine-pitch components, while larger sizes (Type 3) suit standard applications.

- Flux Chemistry: Choose between no-clean, water-soluble, or rosin-based flux depending on cleaning capabilities and residue requirements. No-clean fluxes are widely used for their convenience.

- Viscosity: Ensure the paste’s viscosity matches your stencil printer for consistent application. Typical viscosity ranges from 800-1000 Kcps for standard printing.

Testing different pastes under your specific production conditions is recommended to find the optimal formulation. Factors like storage temperature (typically 2-10°C) and shelf life (often 6-12 months) also influence paste performance.

Best Practices for Handling and Storing SMT Pastes

Proper handling and storage of SMT pastes are essential to maintain their quality and performance:

- Temperature Control: Store pastes in a refrigerator at the recommended temperature to prevent flux separation or hardening.

- Mixing Before Use: Allow the paste to reach room temperature (around 25°C) for 4-6 hours before use, then mix it thoroughly to ensure uniform consistency.

- Avoid Contamination: Use clean tools and containers to prevent introducing impurities that could affect soldering performance.

- Monitor Expiry: Use pastes within their shelf life to avoid issues like poor printability or reduced flux activity.

Future Trends in SMT Pastes and Assembly

The electronics industry is constantly evolving, and SMT pastes are no exception. Emerging trends include:

- Low-Temperature Alloys: New lead-free alloys with lower melting points (around 140-170°C) are being developed to reduce energy consumption and component stress.

- Nano-Particle Pastes: Research into nano-sized solder particles aims to improve performance for ultra-fine-pitch applications below 0.3mm.

- Enhanced SPI Integration: Future SPI systems may incorporate artificial intelligence to predict defects and optimize paste application in real-time.

Staying ahead of these trends can give manufacturers a competitive edge, ensuring they meet the demands of next-generation electronics.

Conclusion

SMT pastes are a cornerstone of modern electronics manufacturing, enabling the precise and reliable assembly of PCBs through surface mount technology. Whether you're navigating the shift to lead-free options or implementing solder paste inspection to enhance quality, understanding the nuances of SMT pastes is essential for success. By choosing the right paste, optimizing your SMT assembly process, and leveraging advanced SPI techniques, you can achieve higher yields and better product reliability.

At ALLPCB, we're committed to supporting your electronics projects with cutting-edge solutions and expertise. From sourcing high-quality materials to providing guidance on assembly processes, we're here to help you succeed in the fast-paced world of electronics manufacturing.