When it comes to producing a PCB stencil for your printed circuit board assembly, one of the biggest decisions you'll face is whether to partner with a local manufacturer or opt for an overseas manufacturer. Both options have their pros and cons, and the right choice depends on your project's needs, budget, timeline, and quality expectations. In short, a local PCB manufacturer often offers faster turnaround times and easier communication, while a PCB manufacturer overseas typically provides lower costs but with potential challenges in logistics and quality control. In this detailed guide, we'll dive deep into the factors to consider when choosing between a local stencil PCB provider and an overseas stencil local alternative, helping you make an informed decision for your next project.

What Is a PCB Stencil and Why Does It Matter?

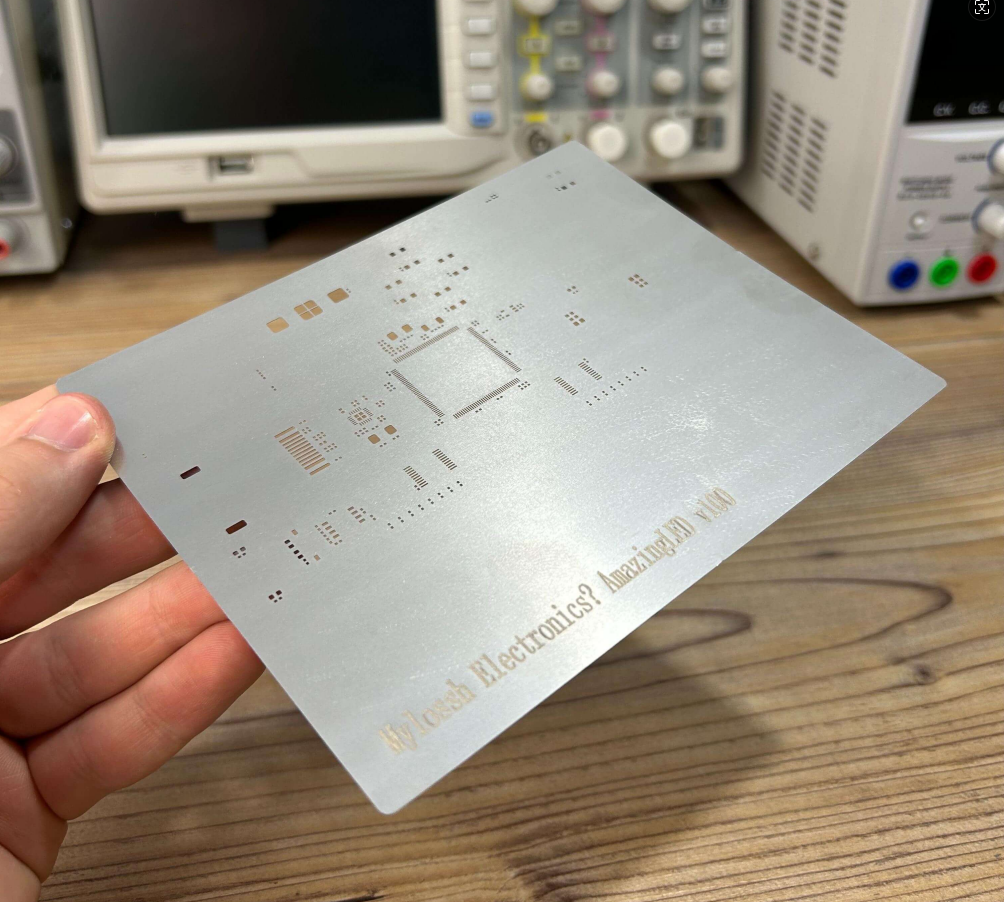

A PCB stencil is a thin sheet, usually made of stainless steel, used to apply solder paste onto a printed circuit board during the surface mount technology (SMT) assembly process. The stencil ensures that the solder paste is deposited precisely on the board's pads, allowing components to be placed accurately before reflow soldering. The quality of the stencil directly impacts the accuracy of solder paste application, which can affect the reliability and performance of the final product.

Choosing the right manufacturer for your PCB stencil is critical because even small errors in stencil design or production can lead to issues like insufficient solder, bridging, or component misalignment. Whether you go with a manufacturer local overseas or a nearby provider, understanding the trade-offs is essential for achieving optimal results.

Advantages of Choosing a Local PCB Manufacturer

Partnering with a local PCB manufacturer for your stencil production comes with several benefits, especially if time and communication are priorities for your project. Let's break down the key advantages:

1. Faster Turnaround Times

One of the most significant benefits of working with a local provider is the speed of delivery. Since the manufacturer is geographically closer, shipping times are drastically reduced. For instance, a local manufacturer might deliver your PCB stencil within 1-3 days, while an overseas shipment could take 1-3 weeks, depending on customs and logistics. This is particularly important for projects with tight deadlines or when rapid prototyping is needed.

2. Easier Communication and Collaboration

Working with a local manufacturer often means fewer language barriers and time zone differences. You can discuss your stencil specifications, request revisions, or address issues in real-time without waiting for responses across a 12-hour time gap. This streamlined communication can prevent misunderstandings in stencil design, such as incorrect aperture sizes or misaligned fiducials (positioning points often 1mm in diameter used for automated machines).

3. Better Quality Control and Accountability

A local stencil PCB provider is typically easier to hold accountable for quality issues. If there are defects in the stencil—like uneven thickness or laser-cut errors—you can quickly return the product or request a replacement. Additionally, local manufacturers often adhere to strict regional standards, ensuring consistent quality. Many local providers also allow for in-person visits to inspect facilities or discuss complex designs, giving you peace of mind.

4. Support for Local Economy

Choosing a local manufacturer supports businesses in your area, contributing to job creation and economic growth. This can also align with corporate social responsibility goals, especially if your company prioritizes sustainable or community-focused practices.

Disadvantages of a Local PCB Manufacturer

While there are clear benefits to working with a local provider, there are also some drawbacks to consider before making your decision.

1. Higher Costs

Local manufacturers often charge more for PCB stencils due to higher labor and operational costs in many regions. For example, a stainless steel stencil for a small prototype run might cost $50-$100 locally, whereas an overseas manufacturer could offer the same product for $20-$40. If cost is a primary concern, especially for large-scale production, this price difference can add up quickly.

2. Limited Capacity for Bulk Orders

Some local manufacturers may not have the capacity to handle large-volume orders or specialized stencil designs. If your project requires hundreds of stencils or complex multi-layer designs, you might find that local providers lack the necessary equipment or expertise compared to larger overseas facilities.

Advantages of Choosing a PCB Manufacturer Overseas

Opting for a PCB manufacturer overseas can be an attractive choice, especially for cost-conscious projects or bulk orders. Here are the main reasons why many businesses go this route:

1. Lower Production Costs

The most compelling reason to choose an overseas manufacturer is the cost savings. Labor and material costs are often significantly lower in certain regions, allowing manufacturers to offer competitive pricing on PCB stencils. For instance, a framed stencil (used for automated machines) that might cost $150 locally could be priced at $60-$80 from an overseas supplier, even after factoring in shipping.

2. Access to Advanced Technology and Expertise

Many overseas manufacturers specialize in high-volume production and invest heavily in cutting-edge technology. This can result in high-precision stencils with features like laser-cut apertures with tolerances as tight as ±0.01mm. If your project demands advanced stencil designs or materials like polyimide for specific applications, an overseas provider might have more options available.

3. Scalability for Large Orders

For companies needing large quantities of PCB stencils, overseas manufacturers often have the infrastructure to handle bulk production efficiently. This scalability can be a game-changer for businesses looking to reduce per-unit costs during mass production runs.

Disadvantages of a PCB Manufacturer Overseas

While the cost benefits are appealing, there are notable challenges when working with an overseas stencil local provider. These drawbacks can impact your project timeline and quality.

1. Longer Lead Times

Shipping from an overseas manufacturer can take weeks, especially if there are delays at customs or during peak shipping seasons. Even with express shipping options, which can cost significantly more, you might still face delays of 5-10 days compared to a local provider’s next-day delivery. This can be problematic for urgent projects or last-minute design changes.

2. Communication Challenges

Time zone differences and language barriers can complicate communication with an overseas manufacturer. Misunderstandings about stencil specifications—like aperture shapes or frame dimensions—can lead to costly errors. While many overseas providers offer customer support, responses may not be as immediate or detailed as with a local partner.

3. Quality and Consistency Risks

Quality control standards can vary widely among overseas manufacturers. Without the ability to inspect the facility or easily return defective products, you might receive stencils that don’t meet your expectations. For example, uneven stencil thickness (typically 0.1mm to 0.2mm for most SMT applications) can cause inconsistent solder paste application, leading to assembly failures.

4. Hidden Costs

While the upfront cost of stencils from overseas may be lower, hidden expenses like shipping fees, customs duties, and dimensional weight charges (especially for framed stencils) can offset the savings. Additionally, if a stencil arrives damaged or incorrect, the cost and time to resolve the issue can be significant.

Key Factors to Consider When Choosing Between Local and Overseas Manufacturers

Deciding between a manufacturer local overseas and a nearby provider requires careful evaluation of your project’s specific needs. Here are the critical factors to weigh:

1. Project Timeline

If your project is time-sensitive, a local manufacturer is often the better choice due to faster shipping and easier coordination. For longer-term projects or bulk orders where timing is flexible, an overseas provider might be more cost-effective.

2. Budget Constraints

For small runs or prototypes, the higher cost of a local stencil might be justified by speed and quality assurance. However, for large-scale production, the cost savings from an overseas manufacturer could outweigh the logistical challenges.

3. Quality Requirements

Consider the complexity of your PCB design and the precision required for the stencil. For high-reliability applications (e.g., medical or aerospace devices), a local manufacturer with strict quality controls might be safer. For less critical projects, an overseas provider with good reviews could suffice.

4. Volume and Scalability

Determine whether your project requires a one-off stencil or hundreds for mass production. Local manufacturers may struggle with large orders, while overseas providers are often better equipped for scalability.

5. Communication Needs

If your project involves frequent updates or custom stencil designs, working with a local provider can simplify collaboration. For standardized designs with minimal back-and-forth, an overseas manufacturer might work just fine.

How to Ensure Quality Regardless of Manufacturer Location

Whether you choose a local PCB manufacturer or a PCB manufacturer overseas, there are steps you can take to ensure the quality of your PCB stencil:

- Provide Detailed Specifications: Clearly define your stencil requirements, including material (e.g., stainless steel or polyimide), thickness (e.g., 0.12mm for fine-pitch components), and aperture tolerances (e.g., ±0.005mm for high-precision designs).

- Request Samples: Before committing to a full order, ask for a sample stencil to test for accuracy and compatibility with your SMT process.

- Check Reviews and References: Research the manufacturer’s reputation through online reviews or by requesting references from past clients.

- Verify Standards Compliance: Ensure the manufacturer follows industry standards like IPC (Institute of Printed Circuits) for stencil production to guarantee reliability.

- Plan for Contingencies: Build extra time into your schedule for potential delays, especially with overseas shipping, and have a backup plan for defective products.

Conclusion: Making the Right Choice for Your PCB Stencil

Deciding between a local stencil PCB manufacturer and an overseas stencil local provider ultimately comes down to balancing cost, speed, quality, and communication. A local PCB manufacturer is ideal for projects requiring quick turnarounds, hands-on collaboration, and assured quality, even if it comes at a higher price. On the other hand, a PCB manufacturer overseas offers significant cost savings and scalability for large orders, though it requires careful planning to manage longer lead times and potential quality risks.

By evaluating your project’s specific needs—whether it’s a tight deadline for a prototype or a cost-effective solution for mass production—you can make an informed decision that aligns with your goals. At ALLPCB, we’re committed to helping you navigate these choices with expert guidance and tailored solutions for your PCB stencil needs. No matter which path you choose, ensuring clear specifications and thorough vetting of your manufacturer local overseas will set your project up for success.

ALLPCB

ALLPCB