When it comes to assembling printed circuit boards (PCBs), two primary soldering techniques stand out: reflow soldering and wave soldering. If you're wondering how to distinguish between these methods, the key difference lies in their application and process. Reflow soldering is ideal for surface mount technology (SMT) components, using a controlled heating process to melt solder paste and secure components to the board. Wave soldering, on the other hand, is typically used for through-hole components, where a wave of molten solder connects leads to the PCB. In this comprehensive guide, we'll dive deep into the differences, processes, advantages, and applications of reflow and wave soldering to help you understand which method suits your PCB assembly needs.

What is Reflow Soldering?

Reflow soldering is a widely used technique in modern PCB assembly, especially for surface mount technology (SMT) components. This method involves applying solder paste—a mixture of tiny solder particles and flux—to the PCB's pads. Components are then placed on the paste, and the entire board is heated in a reflow oven. The heat melts the solder, creating strong electrical and mechanical connections as it cools and solidifies.

The reflow process is highly precise, making it perfect for small, densely packed components common in today's compact electronics. It typically follows a specific temperature profile with four stages: preheat, soak, reflow, and cooling. Each stage is carefully controlled to prevent thermal shock to components and ensure reliable solder joints. For instance, during the preheat stage, the temperature gradually rises to around 150°C to 180°C over 60-90 seconds to activate the flux and remove moisture. The reflow stage peaks at about 220°C to 260°C, depending on the solder type, to melt the paste completely.

What is Wave Soldering?

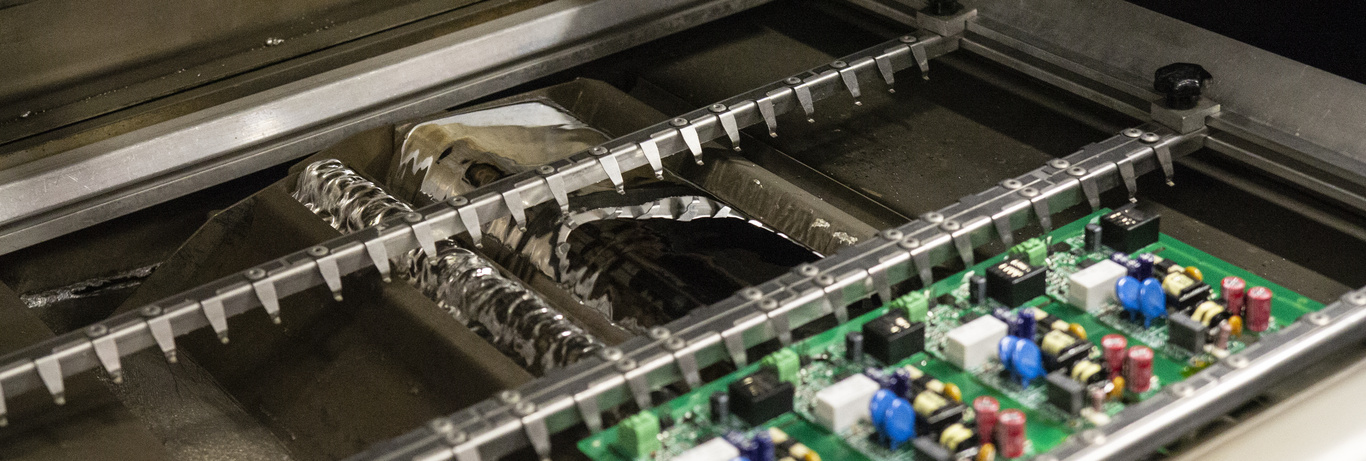

Wave soldering is a traditional soldering method primarily used for through-hole components, though it can also handle some SMT parts in mixed-technology boards. In this process, the PCB is passed over a pot of molten solder, creating a "wave" that contacts the bottom of the board. The solder adheres to the exposed metal areas, such as component leads and pads, forming solid connections as the board cools.

This technique is faster and more cost-effective for high-volume production of boards with through-hole components. However, it requires careful preparation, including masking areas that shouldn't be soldered. The molten solder is typically maintained at a temperature of around 250°C to 260°C, and the PCB passes over the wave at a speed of about 1.5 to 2 meters per minute to ensure proper wetting and connection without overheating components.

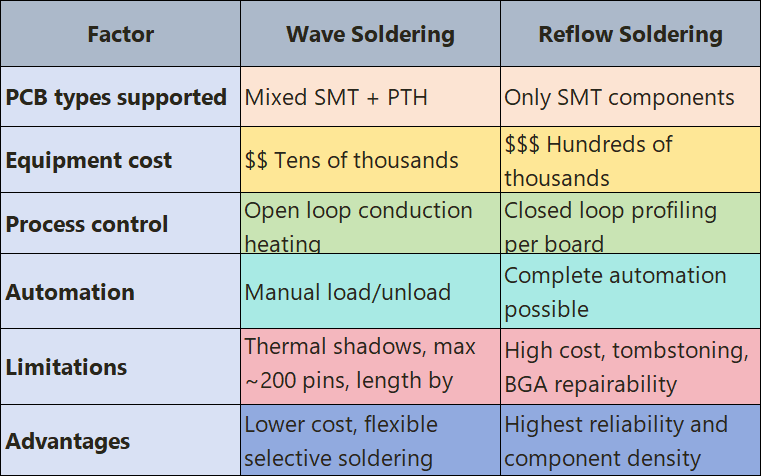

Key Differences Between Reflow Soldering and Wave Soldering

Understanding the distinctions between reflow and wave soldering is crucial for selecting the right method for your PCB assembly. Let's break down the major differences across several factors:

1. Component Type

Reflow soldering is designed for SMT components, which are mounted directly onto the surface of the PCB. These components are smaller and allow for higher density on the board. Wave soldering, conversely, is best suited for through-hole components, where leads are inserted into holes on the PCB and soldered on the opposite side. While wave soldering can sometimes be used for SMT in mixed assemblies, it's less common and less precise for these parts.

2. Process and Equipment

In reflow soldering, the process involves applying solder paste, placing components, and heating the entire board in a reflow oven with a controlled temperature profile. Wave soldering uses a conveyor to move the PCB over a wave of molten solder, focusing the soldering action on the bottom side of the board. The equipment for wave soldering is generally simpler but less versatile for modern SMT designs compared to reflow ovens.

3. Precision and Control

Reflow soldering offers greater precision due to the controlled heating environment and the ability to tailor temperature profiles to specific components and solder types. This reduces the risk of defects like tombstoning or insufficient wetting. Wave soldering, while efficient for through-hole parts, can sometimes result in uneven solder distribution or bridging, especially on densely populated boards.

4. Speed and Volume

Wave soldering is typically faster for large-scale production of through-hole or mixed-technology boards, as it solders multiple connections in one pass. Reflow soldering, while slower per board due to the multi-stage heating process, is often more efficient for SMT assembly because of automation and the ability to handle complex, high-density designs.

5. Cost Considerations

The initial setup for wave soldering equipment can be less expensive than for reflow soldering systems, especially for high-volume production. However, reflow soldering is more cost-effective in the long run for SMT-focused manufacturing due to reduced labor and rework costs. Additionally, solder paste used in reflow can be more expensive than the bulk solder used in wave soldering.

Advantages and Disadvantages of Reflow Soldering

Advantages

- High Precision: Reflow soldering provides excellent control over the soldering process, ensuring consistent, high-quality joints for SMT components.

- Suitable for Dense Designs: It supports compact, high-density PCB layouts, which are common in modern electronics like smartphones and wearables.

- Automation-Friendly: The process integrates well with automated pick-and-place machines, reducing manual labor.

- Reduced Thermal Stress: Controlled temperature profiles minimize the risk of thermal damage to sensitive components.

Disadvantages

- Higher Initial Cost: Reflow ovens and related equipment can be expensive to set up, especially for small-scale production.

- Not Ideal for Through-Hole: It’s less effective for through-hole components, often requiring additional soldering methods for mixed-technology boards.

- Complex Setup: Optimizing temperature profiles and managing solder paste application requires expertise and testing.

Advantages and Disadvantages of Wave Soldering

Advantages

- High Throughput: Wave soldering is fast and efficient for large-volume production, especially with through-hole components.

- Cost-Effective for Bulk: It’s more economical for simpler boards and bulk soldering due to lower material and setup costs.

- Reliable for Through-Hole: Creates strong, durable joints for through-hole components, ideal for power electronics and industrial applications.

Disadvantages

- Limited Precision: Less control over solder application can lead to defects like bridging or incomplete joints on complex boards.

- Not Ideal for SMT: Struggles with the precision needed for small SMT components, often requiring masking or secondary processes.

- Thermal Stress Risk: Direct exposure to molten solder can cause thermal shock to delicate components if not managed properly.

When to Use Reflow Soldering?

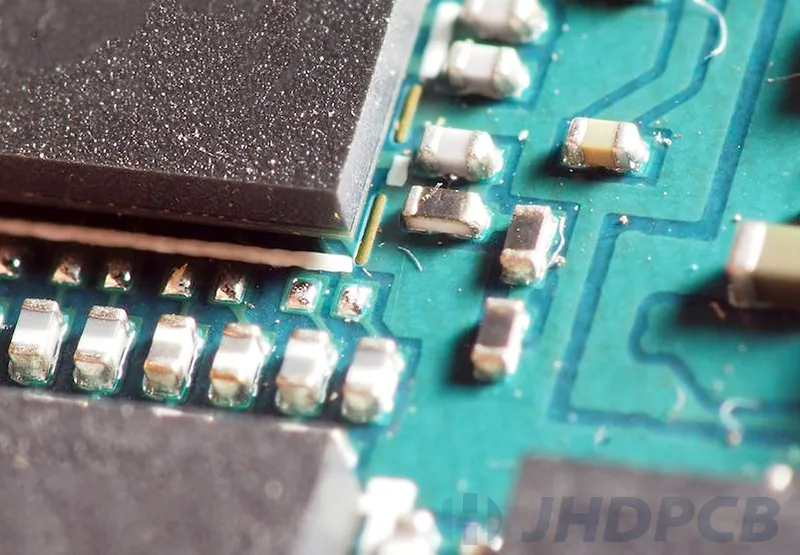

Reflow soldering is the go-to choice for most modern PCB assemblies, especially when working with SMT components. It’s ideal for applications where precision and miniaturization are critical, such as consumer electronics, medical devices, and telecommunications equipment. If your design features components with fine pitch leads (e.g., 0.5mm or less) or requires a high density of parts, reflow soldering ensures reliable connections without compromising quality.

This method is also preferred in automated production lines where consistency and repeatability are essential. For instance, in the production of a smartphone motherboard, reflow soldering can handle hundreds of tiny components with pinpoint accuracy, achieving defect rates as low as 1-2% when optimized properly.

When to Use Wave Soldering?

Wave soldering shines in scenarios involving through-hole components or mixed-technology boards, particularly for high-volume manufacturing. It’s commonly used in industries like automotive, industrial controls, and power electronics, where robust mechanical connections are needed. For example, in a power supply board with large capacitors and connectors, wave soldering ensures strong joints that can withstand mechanical stress and high currents.

While wave soldering is less common in fully SMT designs, it remains a valuable option for cost-sensitive projects with simpler layouts or when speed is a priority over precision for through-hole assembly.

Can Reflow and Wave Soldering Be Combined?

In many cases, PCB designs include both SMT and through-hole components, requiring a combination of reflow and wave soldering. Typically, SMT components are soldered first using the reflow process. Then, through-hole components are inserted and soldered via wave soldering or selective soldering (a more precise variant of wave soldering). This hybrid approach ensures each component type is handled with the most suitable method.

However, combining these processes requires careful planning. For instance, SMT components on the bottom side of the board may need to be glued in place before wave soldering to prevent them from falling off. Additionally, thermal profiles must be managed to avoid re-melting reflowed joints during the wave process, which could lead to defects.

Tips for Choosing the Right Soldering Method

Selecting between reflow and wave soldering depends on several factors related to your PCB design and production goals. Here are some practical tips to guide your decision:

- Analyze Component Types: If your board is predominantly SMT, opt for reflow soldering. For through-hole or mixed designs, consider wave soldering or a combined approach.

- Consider Production Volume: For high-volume, simpler through-hole boards, wave soldering offers speed and cost savings. For complex, low-to-medium volume SMT boards, reflow is more efficient.

- Evaluate Board Density: High-density designs with small components benefit from the precision of reflow soldering.

- Assess Budget Constraints: While reflow equipment may have a higher upfront cost, it can save money in the long term through automation and reduced defects.

- Test and Optimize: Regardless of the method, always test your soldering process with prototypes to fine-tune parameters like temperature, speed, and solder application for the best results.

Common Challenges and Solutions in Soldering

Both reflow and wave soldering come with potential challenges that can affect the quality of your PCB assembly. Here are some common issues and how to address them:

Reflow Soldering Challenges

- Tombstoning: This occurs when one end of a component lifts off the pad during reflow. To prevent it, ensure even heating and proper solder paste application, maintaining a preheat rate of 1.5-3°C per second.

- Insufficient Wetting: If solder doesn’t fully bond to pads, check for contamination or adjust the temperature profile to extend the time above liquidus (TAL) to 30-60 seconds.

Wave Soldering Challenges

- Solder Bridging: Excess solder can connect adjacent pads or leads. Optimize wave height and conveyor speed (around 1.5 m/min) to minimize excess solder contact.

- Thermal Shock: Rapid heating from the solder wave can damage components. Use a preheat stage (100-130°C for 60 seconds) to reduce temperature gradients.

Conclusion: Making the Right Choice for Your PCB Assembly

Distinguishing between reflow soldering and wave soldering comes down to understanding your PCB design, component types, and production requirements. Reflow soldering excels in precision and is the standard for SMT components in modern, compact electronics. Wave soldering, while older, remains essential for through-hole and mixed-technology boards, offering speed and reliability for specific applications.

By carefully evaluating factors like board complexity, volume, and budget, you can select the most effective soldering method or even combine both for optimal results. At ALLPCB, we’re committed to supporting your PCB assembly needs with expertise and advanced manufacturing solutions tailored to your project. Whether you’re working on intricate SMT designs or robust through-hole boards, mastering these soldering techniques ensures high-quality, reliable outcomes for your electronic products.

ALLPCB

ALLPCB