Are you looking for a way to achieve precision and efficiency in flexible PCB (Flex PCB) fabrication? Laser cutting offers unmatched accuracy and speed for flexible board assembly, making it a top choice for manufacturers working with delicate materials like polyimide and Kapton. In this blog, we’ll dive deep into the world of laser cutting for Flex PCBs, exploring techniques like CO2 laser cutting for flexible circuits, UV laser cutting for flex assemblies, and laser ablation for flex PCB fabrication. We’ll also cover how to optimize laser cutting parameters for flex materials to ensure the best results.

Whether you’re an engineer designing compact wearable devices or a manufacturer aiming to reduce production time, this guide will walk you through the benefits, processes, and best practices of laser cutting in Flex PCB assembly. Let’s get started with everything you need to know to elevate your fabrication process.

What Is Laser Cutting in Flex PCB Fabrication?

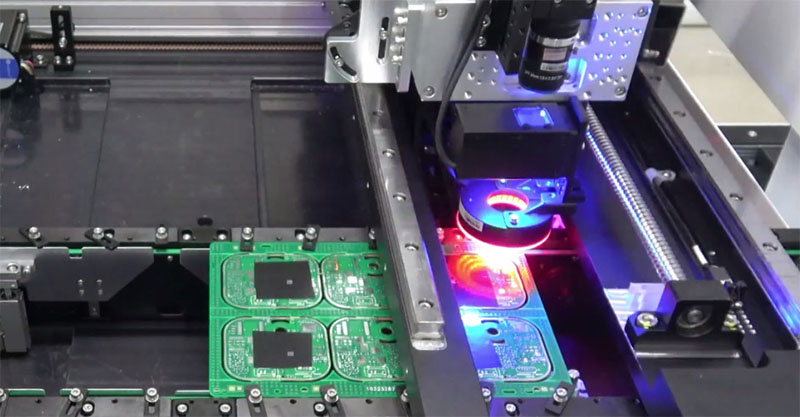

Laser cutting is a non-contact process that uses a focused beam of light to cut or engrave materials with high precision. In the context of Flex PCB fabrication, it is used to shape flexible circuit boards made from thin, pliable materials like polyimide. Unlike traditional mechanical cutting methods, laser cutting minimizes physical stress on the delicate substrate, reducing the risk of damage and ensuring clean edges.

Flex PCBs are essential in modern electronics, found in everything from smartphones to medical devices, due to their ability to bend and fit into tight spaces. Laser cutting enhances the production of these boards by offering precision down to micrometer levels, often achieving tolerances as tight as ±0.025 mm. This level of accuracy is critical when working with intricate designs or multi-layer flexible circuits.

Why Choose Laser Cutting for Flex PCBs?

Laser cutting stands out for several reasons when it comes to flexible board assembly. First, it provides unparalleled precision, which is vital for cutting complex patterns without tearing or deforming the material. Second, it boosts efficiency by reducing production time compared to mechanical methods, as there’s no need for tool changes or extensive setup. Finally, it ensures consistency across large production runs, maintaining quality even at high volumes.

Types of Laser Cutting for Flexible Circuits

Not all laser cutting technologies are the same, and choosing the right one depends on the specific needs of your Flex PCB project. Below, we’ll explore the two main types used in flexible circuit fabrication: CO2 laser cutting and UV laser cutting.

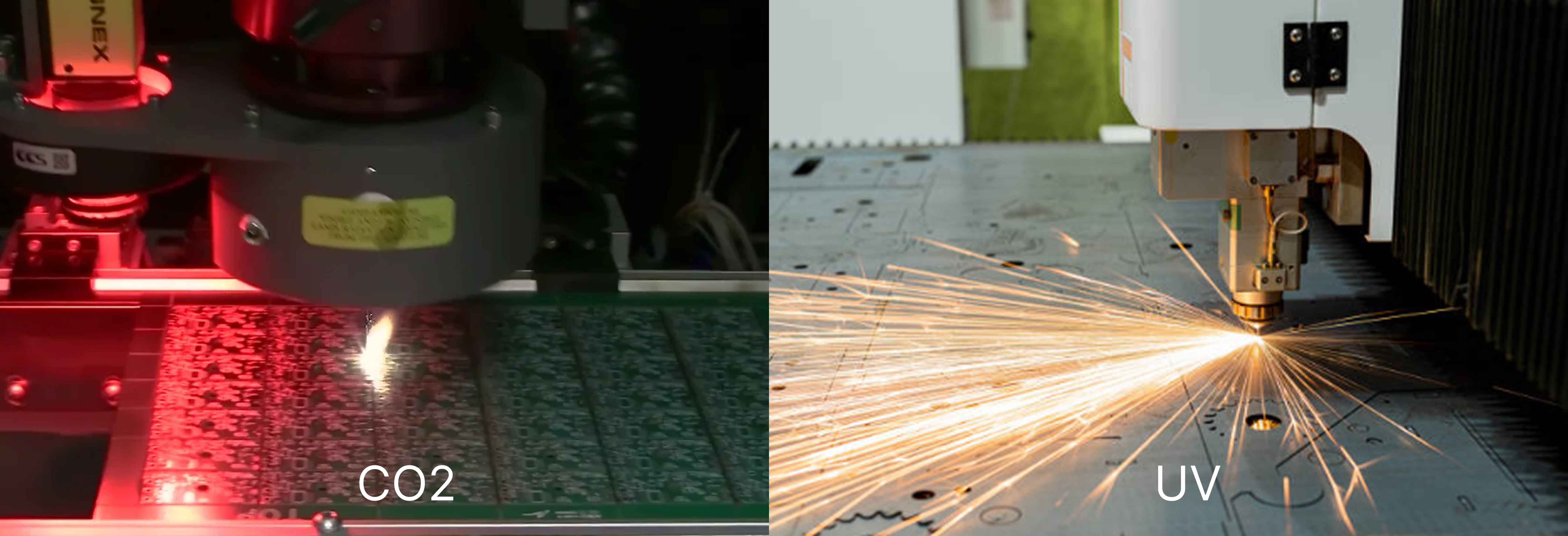

CO2 Laser Cutting for Flexible Circuits

CO2 laser cutting uses a gas-based laser to produce a beam with a wavelength of around 10.6 micrometers. This type of laser is well-suited for cutting thicker flexible materials and coverlays used in Flex PCBs. It excels at processing materials like adhesives and shielding films, often cutting through layers up to 0.5 mm thick with ease.

One key advantage of CO2 laser cutting for flexible circuits is its cost-effectiveness for larger components or less intricate designs. However, it may produce slight heat-affected zones (HAZ) on the material, which can lead to minor charring or discoloration if parameters are not optimized. For most applications, though, this is negligible and does not impact functionality.

UV Laser Cutting for Flex Assemblies

UV laser cutting, on the other hand, operates at a shorter wavelength (typically 355 nm), making it ideal for ultra-precise applications. This technology is often used for cutting thin flexible materials and depaneling complex Flex PCB assemblies. UV lasers minimize heat damage, producing cleaner cuts with virtually no charring, which is critical for sensitive substrates like polyimide films as thin as 0.025 mm.

UV laser cutting for flex assemblies is especially valuable in high-density designs where precision is non-negotiable. It can create intricate features, such as micro-vias with diameters as small as 0.05 mm, without compromising the integrity of surrounding areas. While UV lasers are more expensive to operate than CO2 systems, their superior accuracy often justifies the cost for advanced applications.

Laser Ablation for Flex PCB Fabrication

Laser ablation is a specialized technique often used alongside cutting to remove specific layers of material from a Flex PCB without affecting the underlying substrate. This process is crucial for creating micro-vias, exposing copper traces, or removing coverlay in targeted areas during fabrication.

In laser ablation for Flex PCB fabrication, a high-energy laser beam vaporizes material layer by layer, achieving depth control with accuracies of ±0.01 mm. This method is particularly useful for multi-layer flexible circuits where selective material removal is needed. For instance, laser ablation can create blind vias with aspect ratios of 1:1, ensuring reliable electrical connections in compact designs.

The primary benefit of laser ablation is its ability to work on a microscopic scale, enabling the production of high-density interconnects (HDI) in Flex PCBs. It also reduces the need for chemical etching, making it a more environmentally friendly option for certain fabrication steps.

Benefits of Laser Cutting in Flexible Board Assembly

Laser cutting brings several advantages to the table when it comes to Flex PCB assembly. Let’s break down the key benefits that make it a preferred method for manufacturers and engineers alike.

- Precision: Laser cutting achieves tolerances as tight as ±0.025 mm, ensuring accurate shapes and features even in the most intricate designs.

- Speed: With cutting speeds often exceeding 500 mm per second for thin materials, laser systems significantly reduce production time compared to mechanical methods.

- Flexibility: Lasers can handle a wide range of materials, from polyimide substrates to adhesive layers, without requiring tool changes.

- Minimal Material Stress: As a non-contact process, laser cutting avoids mechanical stress, preventing tears or deformation in delicate flex materials.

- Consistency: Advanced laser systems ensure uniform cuts across large batches, maintaining quality in high-volume production runs.

These benefits translate into cost savings and improved product reliability, especially for applications like wearable electronics, automotive sensors, and medical devices where Flex PCBs are widely used.

Optimizing Laser Cutting Parameters for Flex Materials

To get the best results from laser cutting in Flex PCB fabrication, it’s essential to fine-tune the cutting parameters for the specific materials being used. Optimizing laser cutting parameters for flex materials can mean the difference between a clean, functional board and one with damaged edges or compromised performance.

Key Parameters to Adjust

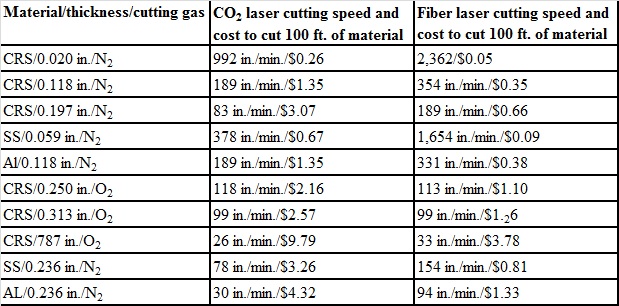

- Laser Power: The power level must match the material thickness and type. For instance, a low power setting of 10-20 W may suffice for thin polyimide films (0.025 mm), while thicker materials might require 50 W or more.

- Cutting Speed: Slower speeds (e.g., 100-200 mm/s) improve precision for intricate designs, while faster speeds (up to 500 mm/s) are better for straight cuts on thicker substrates.

- Pulse Frequency: Adjusting the pulse rate (measured in kHz) controls the energy delivered per pulse. A higher frequency (e.g., 50 kHz) reduces heat buildup for sensitive materials, while a lower frequency (e.g., 20 kHz) is suitable for thicker layers.

- Focus Depth: Proper focusing ensures the laser beam is concentrated at the right depth. For Flex PCBs, a focus tolerance of ±0.1 mm is often ideal to avoid over-cutting or under-cutting.

- Assist Gas: Using an assist gas like nitrogen or air can prevent oxidation and remove debris during cutting, improving edge quality. Nitrogen is often preferred for UV laser cutting to avoid charring.

Testing and calibration are critical when optimizing these parameters. For example, cutting a 0.1 mm polyimide film with a UV laser might require a power setting of 15 W, a speed of 300 mm/s, and a pulse frequency of 40 kHz to achieve a clean edge without thermal damage. Adjusting these values based on trial runs ensures minimal waste and maximum efficiency.

Challenges in Laser Cutting Flex PCBs

While laser cutting offers many advantages, it’s not without challenges. Understanding these potential issues can help you mitigate risks and ensure a smoother fabrication process.

- Heat-Affected Zones (HAZ): Especially with CO2 lasers, excessive heat can cause slight charring or discoloration on flex materials. Using lower power settings or UV lasers can minimize this effect.

- Material Variability: Flex materials like polyimide can vary in thickness or composition, requiring frequent parameter adjustments to maintain consistency.

- Cost: High-precision systems, especially UV lasers, involve significant upfront investment and maintenance costs, which may be a barrier for smaller operations.

- Debris Management: Cutting generates debris that can settle on the board, potentially affecting performance. Proper assist gas flow and post-cut cleaning are essential.

By addressing these challenges through careful planning and equipment calibration, manufacturers can fully leverage the benefits of laser cutting for Flex PCB assembly.

Applications of Laser Cutting in Flex PCB Fabrication

Laser cutting is widely used across industries where Flex PCBs play a critical role. Here are some key applications where this technology shines:

- Wearable Electronics: Devices like smartwatches and fitness trackers rely on compact, flexible circuits. Laser cutting ensures precise shaping of these boards to fit small, curved spaces.

- Medical Devices: Flexible circuits in pacemakers and diagnostic tools require intricate designs that laser cutting can achieve without damaging sensitive materials.

- Automotive Systems: Flex PCBs in sensors and control units benefit from the durability and precision of laser-cut components, ensuring reliable performance under harsh conditions.

- Aerospace: Lightweight and space-saving Flex PCBs in satellites and aircraft systems are often fabricated using laser cutting for high accuracy and consistency.

In each of these applications, laser cutting delivers the precision and efficiency needed to meet strict industry standards while reducing production time and costs.

Future Trends in Laser Cutting for Flex PCBs

As technology advances, laser cutting for Flex PCB fabrication continues to evolve. One emerging trend is the integration of machine vision systems with laser cutting equipment. These systems use cameras to detect material alignment and adjust cutting paths in real-time, achieving even tighter tolerances (down to ±0.01 mm).

Another development is the use of ultrafast lasers, such as femtosecond lasers, which deliver pulses in trillionths of a second. These lasers virtually eliminate heat-affected zones, making them ideal for cutting ultra-thin flex materials without any thermal damage. Though currently expensive, their adoption is expected to grow as costs decrease.

Additionally, automation and AI are being integrated into laser cutting systems to optimize parameters automatically based on material properties and design requirements. This reduces setup time and minimizes human error, further boosting efficiency in large-scale production.

Conclusion

Laser cutting has revolutionized flexible board assembly, offering precision and efficiency that traditional methods can’t match. Whether you’re using CO2 laser cutting for flexible circuits, UV laser cutting for flex assemblies, or laser ablation for Flex PCB fabrication, this technology ensures clean, accurate results with minimal material stress. By optimizing laser cutting parameters for flex materials, manufacturers can achieve consistent quality, reduce waste, and speed up production.

At ALLPCB, we’re committed to staying at the forefront of Flex PCB fabrication technologies, helping engineers and manufacturers bring their designs to life with the highest standards of precision. If you’re ready to explore how laser cutting can enhance your next project, our team is here to support you every step of the way.

With its wide range of applications and continuous advancements, laser cutting is set to remain a cornerstone of Flex PCB manufacturing. Embrace this technology to stay ahead in the fast-paced world of electronics design and production.

ALLPCB

ALLPCB