If you're searching for the best tools for manual pick and place in SMT assembly, you've come to the right place. Whether you're a hobbyist assembling a small batch of PCBs or a professional handling low-volume production, having the right equipment can make all the difference in precision and efficiency. In this comprehensive review, we'll explore top manual pick and place tools, including SMT tweezers and vacuum pick options, to help you choose the best hand placement equipment for your PCB assembly needs.

Below, we'll dive into detailed insights on various SMT assembly tools, their features, benefits, and how they can enhance your workflow. From ergonomic designs to advanced features like vacuum assistance, this guide covers everything you need to know to make an informed decision.

Why Manual Pick and Place Tools Matter in SMT Assembly

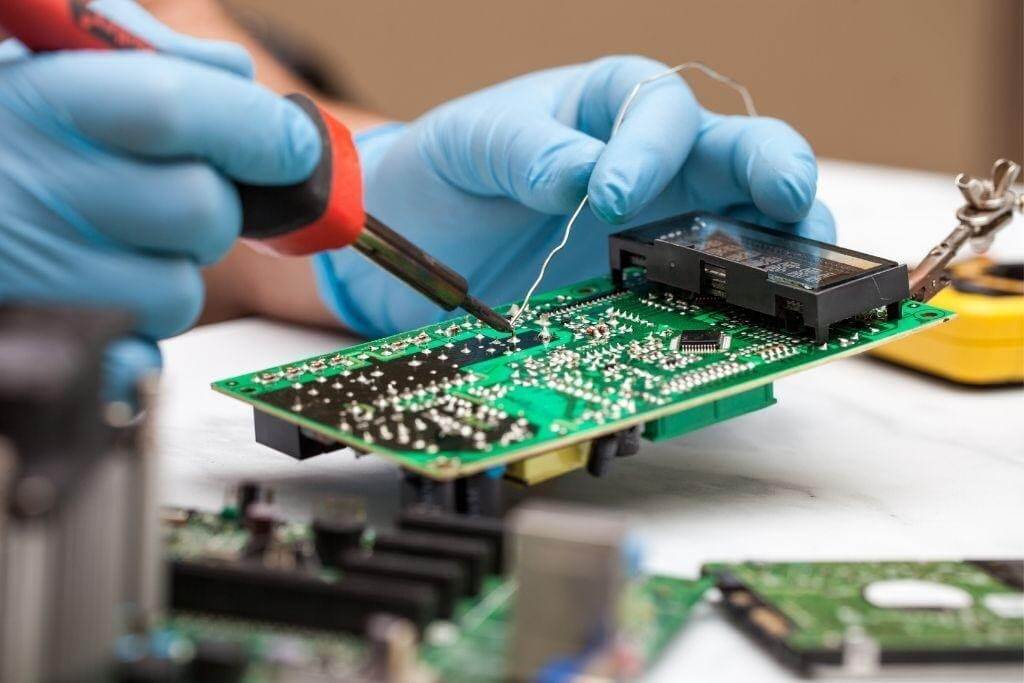

Surface Mount Technology (SMT) assembly is a critical process in modern electronics manufacturing, allowing components to be placed directly onto the surface of printed circuit boards (PCBs). While automated pick and place machines dominate high-volume production, manual tools remain essential for prototyping, small-scale projects, and rework tasks. These tools offer precision, control, and affordability, making them ideal for engineers and hobbyists who need flexibility without investing in expensive machinery.

Manual pick and place tools, such as tweezers and vacuum picks, help ensure accurate component placement, reducing the risk of errors like misalignment or damage to delicate parts. With the right equipment, you can handle components as small as 0402 resistors (measuring just 0.4mm x 0.2mm) or fine-pitch ICs with leads spaced at 0.5mm or less. The result? Faster assembly times, fewer defects, and a smoother workflow.

Key Features to Look for in Manual Pick and Place Tools

Before we review specific tools, let’s break down the essential features to consider when selecting the best hand placement equipment for PCB assembly. These factors will help you match the tool to your specific needs, whether you're working on intricate designs or larger components.

- Ergonomics: Look for tools with comfortable grips to reduce hand fatigue during long assembly sessions. Lightweight designs and balanced weight distribution are key.

- Precision: The tool must allow for accurate placement of tiny components. Fine tips or adjustable vacuum heads are crucial for handling small parts without slippage.

- Versatility: Opt for tools that can handle a range of component sizes, from small resistors and capacitors to larger ICs or connectors.

- Durability: High-quality materials like stainless steel or anti-static coatings ensure longevity and protect components from electrostatic discharge (ESD).

- Ease of Use: Tools with intuitive designs, such as quick-release mechanisms for vacuum picks, save time and improve efficiency.

Keeping these features in mind, let’s explore some of the best categories of manual pick and place tools available for SMT assembly.

Top Categories of Manual Pick and Place Tools for PCB Assembly

1. SMT Tweezers: Precision at Your Fingertips

SMT tweezers are a staple in any PCB assembly toolkit. Designed specifically for handling surface mount components, these tweezers come with ultra-fine tips that allow you to pick, place, and adjust parts with pinpoint accuracy. They are especially useful for components ranging from 0603 (0.6mm x 0.3mm) to larger packages like SOICs.

Benefits of SMT Tweezers:

- High precision for placing components on tight PCB layouts.

- Anti-static coatings to prevent damage to sensitive electronics.

- Affordable and widely available in various tip sizes and shapes.

Drawbacks:

- Can be tiring for extended use due to repetitive hand movements.

- Not ideal for very small components like 0201 packages without significant skill.

When choosing SMT tweezers, prioritize models with ergonomic handles and non-magnetic tips to avoid interference with magnetic-sensitive components. A set with multiple tip shapes (straight, curved, and angled) can cover a wide range of tasks, from placement to rework.

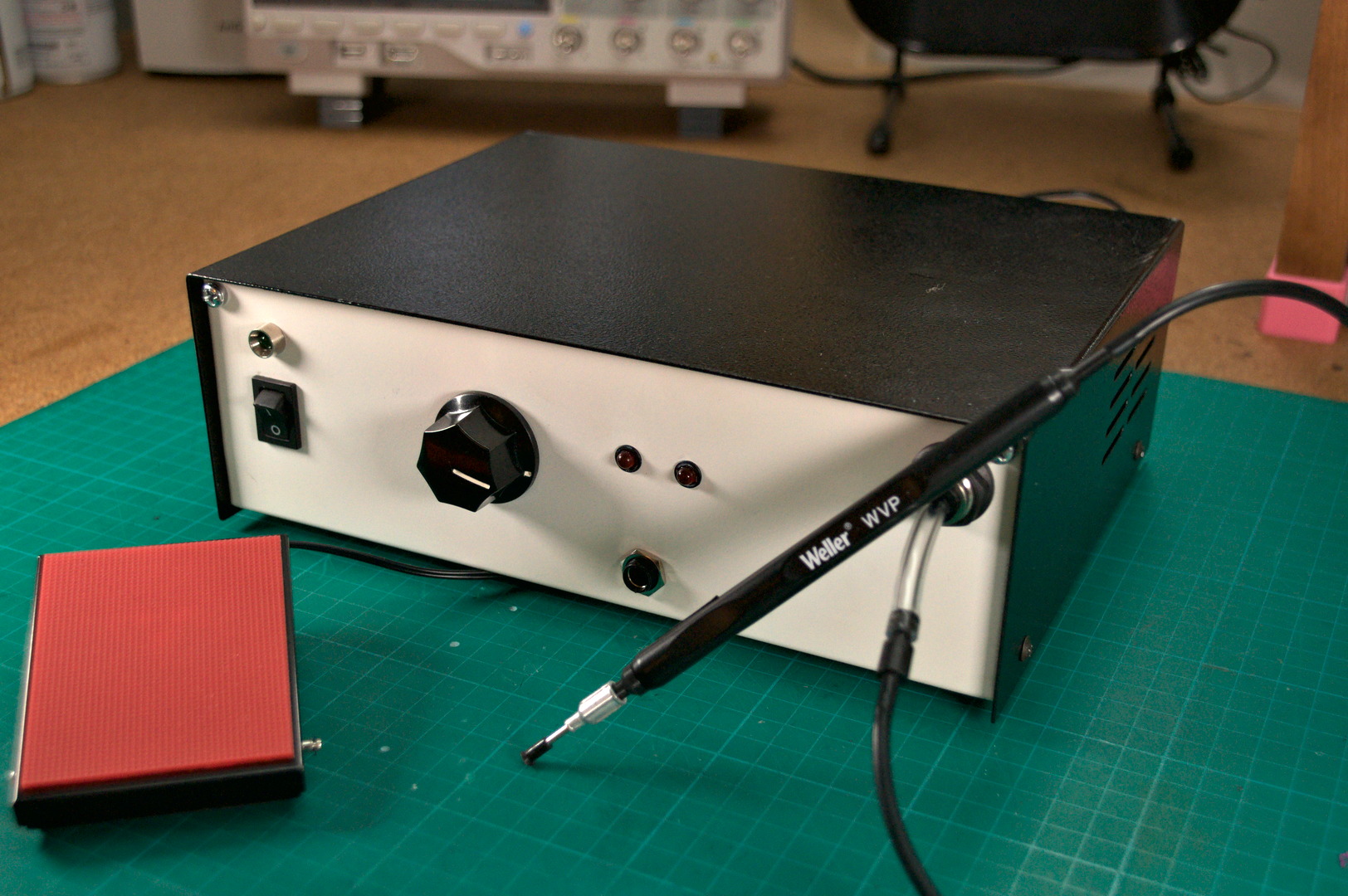

2. Vacuum Pick Tools: Hands-Free Component Handling

Vacuum pick tools, also known as vacuum pens, are a game-changer for manual SMT assembly. These tools use suction to pick up components, eliminating the need to grip them directly. A small pump or bulb creates a gentle vacuum through a nozzle, allowing you to lift and place parts without risking damage from excessive force.

Benefits of Vacuum Pick Tools:

- Reduces the risk of dropping or damaging components during placement.

- Ideal for handling very small parts (down to 0402 or smaller) with ease.

- Some models include adjustable suction levels for different component sizes.

Drawbacks:

- Requires a learning curve to control suction and placement accurately.

- More expensive than basic tweezers, though still affordable for most budgets.

For best results, look for vacuum pick tools with interchangeable nozzles to accommodate various component sizes. Lightweight, handheld models are perfect for small-scale assembly, while desktop units with foot pedals offer hands-free operation for larger projects.

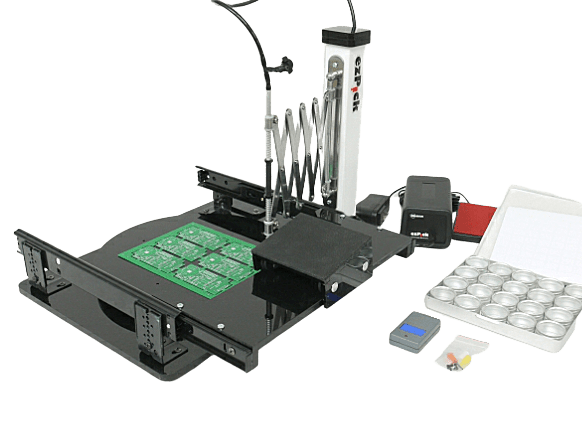

3. Manual Pick and Place Systems: Enhanced Control and Ergonomics

For those who need more than handheld tools, manual pick and place systems provide a semi-automated experience without the high cost of fully automated machines. These systems often feature a manipulator arm, a high-definition camera, and a vacuum pipette, allowing for precise component placement with minimal effort.

Benefits of Manual Pick and Place Systems:

- Ergonomic design reduces strain during long assembly sessions.

- Integrated cameras and monitors assist with placing fine-pitch components (e.g., QFN packages with 0.4mm pitch).

- Supports larger PCB panels, often up to 15” x 11” (380mm x 295mm), depending on the model.

Drawbacks:

- Higher initial cost compared to tweezers or vacuum picks.

- Requires setup and calibration for optimal performance.

These systems are ideal for small to medium-scale production or prototyping labs where precision and speed are critical. They strike a balance between manual control and automation, making them a valuable addition to any SMT assembly setup.

How to Choose the Best Hand Placement Equipment for Your Needs

Selecting the right manual pick and place tools depends on several factors, including the type of projects you undertake, your budget, and your skill level. Here’s a quick guide to help you decide:

- For Hobbyists and Small Projects: Start with a set of SMT tweezers and a basic vacuum pick tool. These are affordable and versatile enough for most small-scale PCB assembly tasks.

- For Prototyping and Rework: Invest in a high-quality vacuum pick with multiple nozzles to handle a variety of components. Look for anti-static features to protect sensitive electronics.

- For Small Batch Production: Consider a manual pick and place system with ergonomic features and visual aids. These tools save time and improve accuracy when assembling multiple boards.

Additionally, evaluate the size and complexity of the components you work with most often. If your designs frequently include fine-pitch parts or micro-sized components, prioritize tools with enhanced precision and visual assistance.

Tips for Using Manual Pick and Place Tools Effectively

Even the best tools require proper technique to deliver optimal results. Here are some practical tips to enhance your SMT assembly process:

- Maintain a Clean Workspace: Dust and debris can interfere with component placement or damage delicate parts. Use an anti-static mat and keep your tools organized.

- Use Proper Lighting: Bright, focused lighting helps you see small components clearly, reducing placement errors.

- Practice Component Handling: Spend time practicing with scrap boards to build confidence in handling tiny parts without dropping or misaligning them.

- Invest in Magnification: A magnifying glass or digital microscope can make a big difference when working with components smaller than 0603.

- Regularly Clean Tools: Residue from solder paste or flux can build up on tweezers and vacuum nozzles, affecting performance. Clean them with isopropyl alcohol after each session.

Conclusion: Elevate Your PCB Assembly with the Right Tools

Manual pick and place tools are indispensable for anyone involved in SMT assembly, offering the precision and control needed for successful PCB production. Whether you opt for SMT tweezers, vacuum pick tools, or a manual pick and place system, choosing the right equipment can significantly improve your efficiency and reduce errors in your workflow.

By focusing on key features like ergonomics, precision, and versatility, you can find the best hand placement equipment tailored to your specific needs. Remember to prioritize quality and proper technique to get the most out of your tools, ensuring every component is placed accurately on your PCB.

At ALLPCB, we understand the importance of reliable tools and resources in electronics manufacturing. We’re committed to supporting your projects with high-quality services and solutions to streamline your assembly process. Explore our offerings to see how we can help bring your designs to life with precision and efficiency.

ALLPCB

ALLPCB