In today’s fast-paced world, mobile phones are indispensable tools, packed with powerful processors and advanced features. However, with great power comes great heat. Overheating in mobile phones can lead to performance issues, reduced battery life, and even hardware damage. So, how do manufacturers ensure your device stays cool under pressure? The answer lies in effective thermal management on mobile phone PCBs (Printed Circuit Boards). In this comprehensive guide, we’ll explore key strategies like PCB thermal vias, heat dissipation techniques, thermal simulation for PCBs, mobile phone overheating solutions, and the role of thermal interface materials in maintaining optimal temperatures.

Whether you’re an engineer designing the next big smartphone or a tech enthusiast curious about how your device works, this blog will break down the essentials of thermal management in a simple, actionable way. Let’s dive into the world of PCB design and discover how to keep mobile phones cool and efficient.

Why Thermal Management Matters for Mobile Phone PCBs

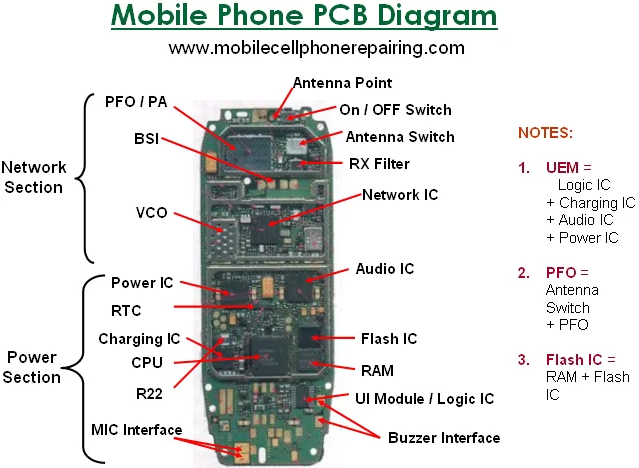

Mobile phones are compact devices with limited space for components, yet they house high-performance chips that generate significant heat during operation. Without proper thermal management, this heat can build up, causing the device to throttle performance, overheat, or even shut down to prevent damage. Effective thermal management on PCBs ensures that heat is dissipated efficiently, maintaining the device’s reliability and user experience.

Thermal issues are especially critical in modern smartphones due to trends like 5G connectivity, high-resolution displays, and powerful gaming capabilities. For instance, a processor running at full capacity can reach temperatures exceeding 80°C (176°F) if not managed properly. This makes thermal design a top priority for engineers working on mobile phone PCBs.

Key Heat Dissipation Techniques for Mobile Phone PCBs

Heat dissipation is the process of transferring heat away from critical components to prevent overheating. Here are some of the most effective heat dissipation techniques used in mobile phone PCB design:

1. Use of Copper Layers for Heat Spreading

Copper is an excellent conductor of heat, making it a popular choice for heat dissipation in PCBs. Designers often use thick copper layers or dedicate entire planes within the PCB stack-up to act as heat spreaders. These layers draw heat away from hot components and distribute it across a larger area, reducing localized temperature spikes.

For example, a PCB might include a copper plane with a thickness of 2 oz/ft2 (about 70 micrometers) to enhance thermal conductivity. This technique is especially useful in compact mobile phone designs where space for additional cooling solutions is limited.

2. Strategic Component Placement

Placing heat-generating components like processors and power management ICs away from each other can prevent heat concentration. Designers also position these components near the edges of the PCB or closer to heat sinks to facilitate better heat transfer. By optimizing layout, engineers can reduce thermal stress on sensitive areas of the board.

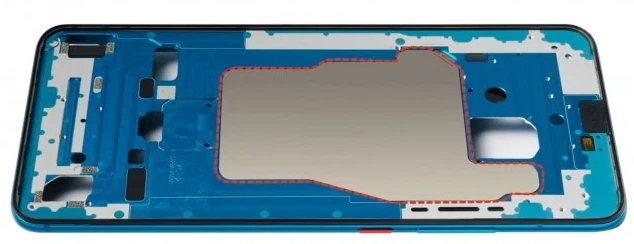

3. Heat Sinks and Vapor Chambers

While space is tight in mobile phones, miniature heat sinks or vapor chambers are often integrated into the design. Vapor chambers, in particular, are thin, lightweight solutions that use a liquid-to-vapor phase change to transfer heat efficiently. These are placed directly above high-heat components to absorb and dissipate energy away from the PCB.

The Role of PCB Thermal Vias in Heat Management

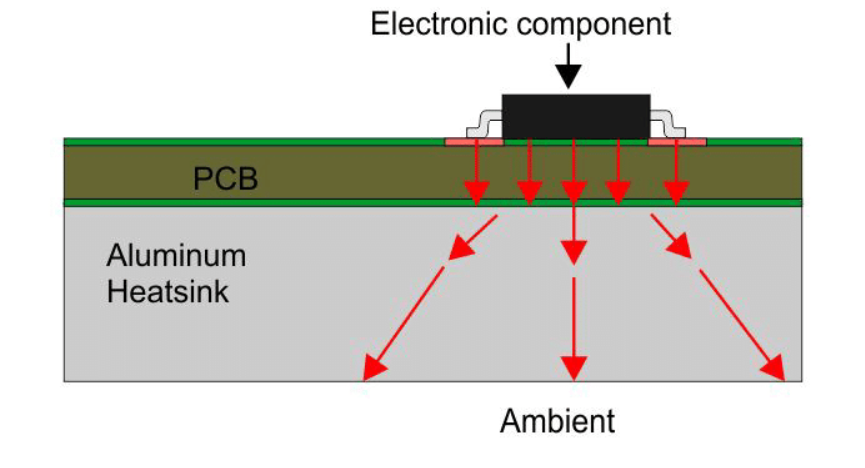

One of the most effective ways to manage heat in a PCB is through the use of thermal vias. These are small, plated-through holes that connect different layers of the PCB, allowing heat to transfer from hot components on the top layer to a heat-dissipating layer or structure on the bottom.

Thermal vias work by providing a low-resistance path for heat to escape. They are often placed directly under or near high-heat components like CPUs or GPUs. For optimal performance, engineers might use an array of vias with a diameter of 0.3 mm and a spacing of 1.2 mm, filled with a conductive material to enhance thermal conductivity.

In mobile phone PCBs, where multilayer designs are common, thermal vias are critical for moving heat to internal copper planes or external heat sinks. Without them, heat could remain trapped, leading to component failure or reduced device lifespan.

Thermal Simulation for PCB Design: Predicting and Preventing Overheating

Designing a thermally efficient PCB isn’t just about adding vias or copper layers; it’s also about predicting how heat will behave under real-world conditions. This is where thermal simulation for PCBs comes into play. Using specialized software, engineers can model heat flow, identify hotspots, and test different design configurations before manufacturing.

Thermal simulation tools analyze factors like component power dissipation, ambient temperature, and material properties. For instance, a simulation might reveal that a processor dissipating 5 watts of power could cause a temperature rise of 40°C in a specific area of the PCB. Armed with this data, designers can adjust the layout, add thermal vias, or select better materials to mitigate overheating risks.

In mobile phone design, thermal simulation is invaluable for ensuring that the device remains cool during intensive tasks like gaming or video streaming. It helps engineers create reliable products that meet strict performance and safety standards.

Mobile Phone Overheating Solutions: Beyond PCB Design

While PCB design plays a major role in thermal management, there are additional mobile phone overheating solutions that complement these efforts. These solutions address heat at both the hardware and software levels to keep your device running smoothly.

1. Advanced Cooling Systems

Some high-end mobile phones incorporate advanced cooling systems like liquid cooling or graphene-based heat spreaders. Graphene, for instance, has a thermal conductivity of up to 5000 W/m·K, making it incredibly effective at dissipating heat in a thin, lightweight form factor.

2. Software Optimization

Software plays a surprising role in thermal management. Many modern phones use dynamic thermal throttling, which reduces processor speed when temperatures rise too high. This prevents overheating by balancing performance with safety. Additionally, operating systems may limit background processes or notify users to close power-intensive apps.

3. Device Design and Materials

The phone’s outer casing and internal structure also contribute to heat dissipation. Using materials with high thermal conductivity for the frame or back panel can help release heat into the environment. Ventilation slots or perforations, though rare in modern designs due to water resistance requirements, can also aid in cooling.

Thermal Interface Materials: Bridging the Gap for Better Heat Transfer

Thermal interface materials (TIMs) are essential for improving heat transfer between components and heat dissipation structures. These materials fill microscopic gaps between surfaces, reducing thermal resistance and ensuring efficient heat flow.

In mobile phone PCBs, TIMs are commonly used between the processor and a heat sink or vapor chamber. Popular options include thermal pastes, pads, and phase-change materials. For example, a thermal paste with a conductivity of 8 W/m·K can significantly lower the temperature of a chip by ensuring better contact with the cooling solution.

Choosing the right TIM is critical for long-term reliability. Poor-quality materials can degrade over time, leading to reduced performance or overheating. Engineers must balance factors like conductivity, thickness, and durability when selecting TIMs for mobile devices.

Challenges in Thermal Management for Mobile Phones

Despite the advancements in thermal management, designing for heat dissipation in mobile phones remains a complex challenge. Here are some key hurdles engineers face:

- Compact Size: Mobile phones are getting thinner, leaving little room for bulky cooling solutions.

- High Power Density: As chips become more powerful, they generate more heat in a smaller area, increasing the risk of hotspots.

- Cost Constraints: Advanced materials like graphene or sophisticated cooling systems can be expensive to implement.

- User Expectations: Consumers demand high performance without sacrificing battery life or dealing with overheating issues.

Overcoming these challenges requires innovative thinking and a combination of hardware and software solutions tailored to each device’s unique needs.

Future Trends in Mobile Phone Thermal Management

As mobile technology evolves, so do the strategies for managing heat. Here are some emerging trends that could shape the future of thermal management in mobile phone PCBs:

- Nanomaterials: New materials with exceptional thermal properties, such as carbon nanotubes, could revolutionize heat dissipation in compact devices.

- AI-Driven Thermal Management: Artificial intelligence could optimize thermal performance by predicting heat generation patterns and adjusting system resources in real time.

- Integrated Cooling Solutions: Future designs might embed cooling directly into the PCB or chip packaging, eliminating the need for separate heat dissipation structures.

These advancements promise to keep mobile phones cool even as they become more powerful and feature-rich.

Conclusion: Keeping Mobile Phones Cool with Smart Thermal Management

Thermal management on mobile phone PCBs is a critical aspect of ensuring device performance, reliability, and user satisfaction. By leveraging heat dissipation techniques, PCB thermal vias, thermal simulation for PCBs, mobile phone overheating solutions, and thermal interface materials, engineers can design devices that stay cool under the most demanding conditions.

At ALLPCB, we understand the importance of thermal design in creating high-quality, reliable electronics. Whether you’re working on a new mobile phone prototype or optimizing an existing design, our expertise in PCB manufacturing can help you achieve superior thermal performance. Stay ahead of the heat with smart design practices and innovative solutions that keep your devices running smoothly.

ALLPCB

ALLPCB