When it comes to designing a printed circuit board (PCB), every detail matters, including the color of the silkscreen. So, which is better for your PCB—black silkscreen or white silkscreen? In short, white silkscreen often provides better visibility on darker solder masks like green or black, making it a popular choice for assembly and troubleshooting. However, black silkscreen can be ideal for lighter solder masks or specific aesthetic needs, though it may be less visible in some conditions. The best choice depends on your PCB’s design, manufacturing needs, and assembly environment.

In this comprehensive guide, we’ll dive deep into the comparison of black vs. white silkscreen for PCBs. We’ll explore how each color impacts visibility, assembly, manufacturing, and overall design. Whether you’re an engineer, designer, or hobbyist, this article will help you make an informed decision for your next project.

What is Silkscreen on a PCB?

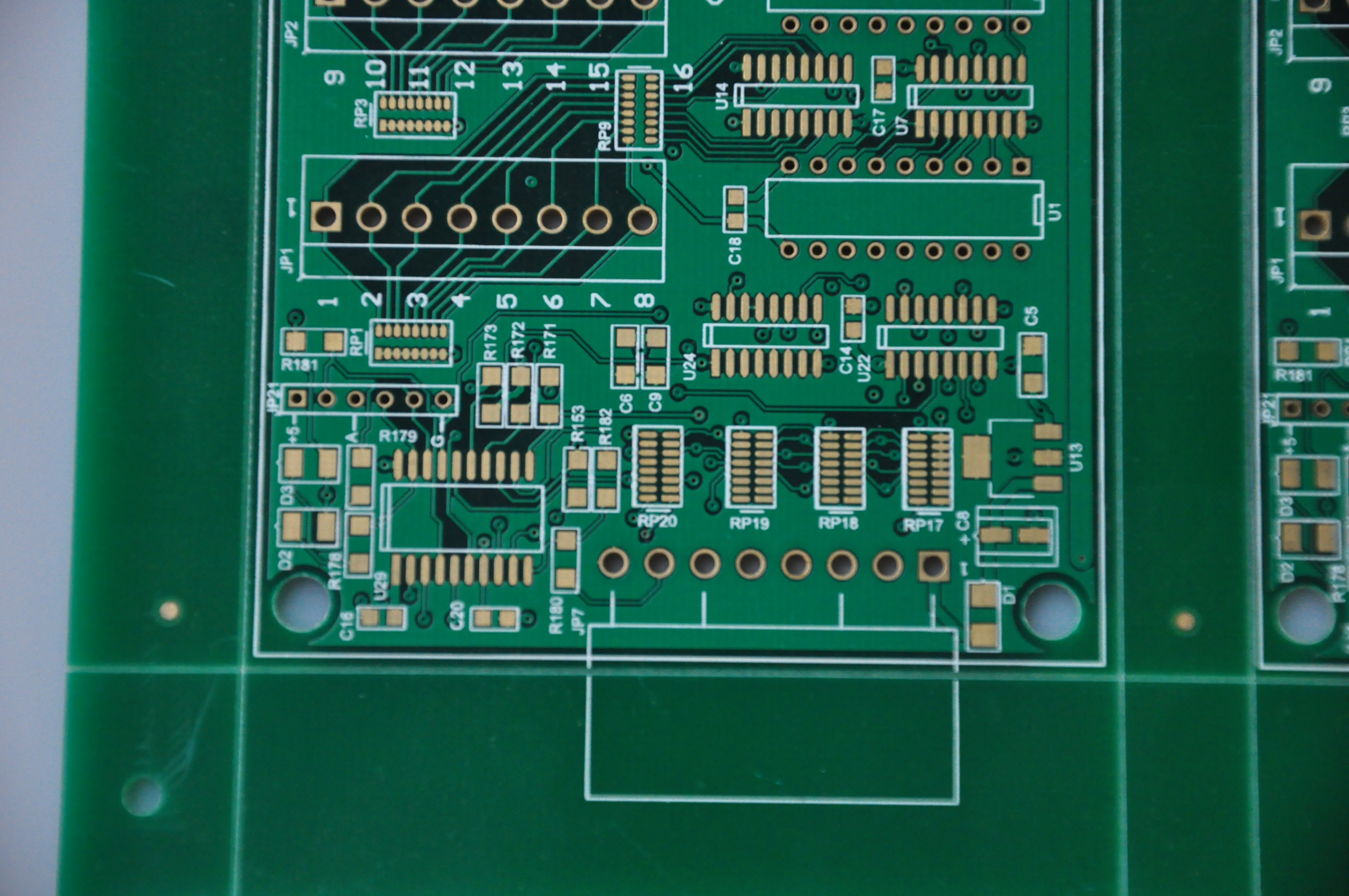

Before we compare black and white silkscreen, let’s clarify what silkscreen is. Silkscreen is a layer of non-conductive ink applied to the surface of a PCB. It’s used to label components, mark test points, indicate polarity, and display logos or other identifying information. This layer is typically added as the final step in the PCB manufacturing process and plays a crucial role in both assembly and troubleshooting.

Silkscreen is most commonly applied to the component side of the board, though it can also appear on the solder side in some cases, often at an additional cost. The ink used is specially formulated to withstand the harsh conditions of PCB assembly, such as high temperatures during soldering. Common silkscreen colors include white, black, and sometimes yellow, with white and black being the most widely used.

Black vs. White Silkscreen: Key Differences

The choice between black and white silkscreen comes down to several factors, including visibility, contrast with the solder mask, cost, and aesthetic preferences. Let’s break down the key differences to help you understand which option suits your needs.

1. Visibility and Contrast

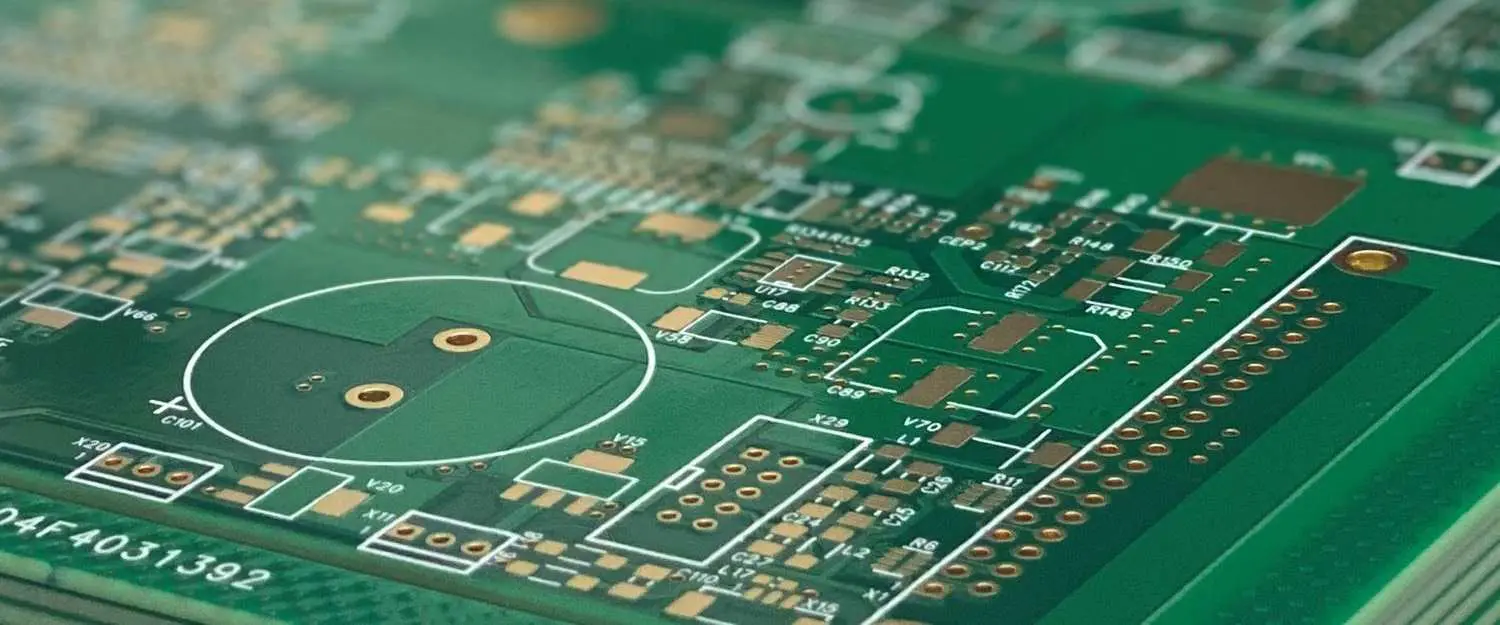

Visibility is one of the most critical factors when choosing a silkscreen color. The silkscreen must stand out against the background color of the solder mask to ensure that labels, symbols, and markings are easy to read during assembly and debugging.

- White Silkscreen: White silkscreen offers high contrast on darker solder masks like green, black, or blue, which are common in PCB designs. This makes it easier for technicians to read component labels and polarity markers, even in low-light conditions. For instance, on a standard green solder mask, white silkscreen can achieve a contrast ratio of up to 4:1, which meets many readability standards for industrial applications.

- Black Silkscreen: Black silkscreen works best on lighter solder masks, such as white or yellow. However, it may not provide sufficient contrast on darker backgrounds, making it harder to read under certain lighting conditions. For example, on a black solder mask, black silkscreen markings can have a contrast ratio as low as 1.2:1, which can strain the eyes during prolonged assembly tasks.

2. Impact on PCB Assembly

During PCB assembly, clear silkscreen markings are essential for placing components accurately and avoiding errors. The color of the silkscreen can directly affect how quickly and accurately assembly technicians can work.

- White Silkscreen: Due to its high visibility on most standard solder masks, white silkscreen often speeds up the assembly process. Technicians can quickly identify component placements and orientations, reducing the risk of errors like incorrect polarity. This is especially important in high-volume production where time efficiency translates to cost savings.

- Black Silkscreen: Black silkscreen can slow down assembly if used on a dark solder mask because of poor contrast. Technicians may need additional lighting or magnification to read the markings, which can increase assembly time. However, on a light-colored solder mask, black silkscreen performs just as well as white in terms of visibility.

3. Role in PCB Manufacturing

The silkscreen color can also influence the manufacturing process, though the impact is often minimal compared to visibility and assembly concerns.

- White Silkscreen: White ink is widely available and commonly used, making it a standard choice in many manufacturing setups. It adheres well to most PCB surfaces and is less prone to fading or smudging during the curing process. Most manufacturers report a defect rate of less than 0.5% for white silkscreen application under standard conditions.

- Black Silkscreen: Black ink is also readily available but may require more careful application to ensure even coverage, especially on darker solder masks where imperfections are less noticeable. Some manufacturers note a slightly higher defect rate of around 0.8% for black silkscreen due to challenges in achieving consistent opacity.

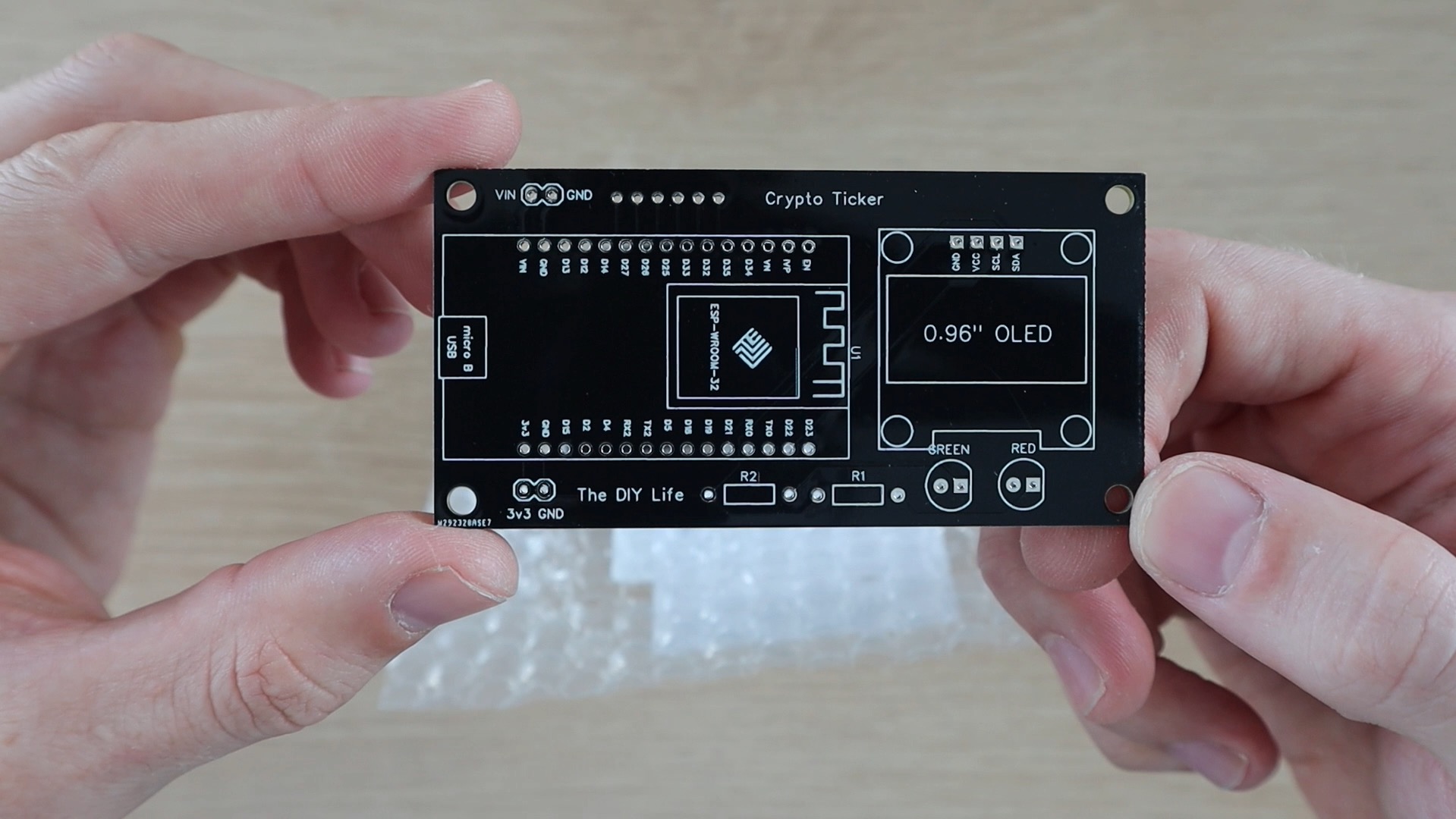

4. Aesthetic Considerations

While functionality is the primary concern, the aesthetic appeal of a PCB can matter, especially for consumer-facing products or prototypes displayed at trade shows.

- White Silkscreen: White silkscreen often gives a clean, professional look, especially on darker solder masks. It's a popular choice for designs where branding or logos are part of the silkscreen layer.

- Black Silkscreen: Black silkscreen can create a sleek, minimalist appearance, particularly on lighter solder masks. It's often chosen for high-end or modern designs where a subtle look is desired.

PCB Silkscreen Color Comparison: Pros and Cons

To make the decision easier, let's summarize the advantages and disadvantages of black and white silkscreen in a clear format.

White Silkscreen

- Pros:

- High contrast on dark solder masks (e.g., green, black, blue).

- Better visibility for assembly and troubleshooting.

- Widely used and supported by most manufacturers.

- Professional and clean appearance.

- Cons:

- Less effective on light-colored solder masks like white or yellow.

- May show dirt or smudges more easily over time.

Black Silkscreen

- Pros:

- Works well on light-colored solder masks.

- Offers a sleek, modern aesthetic.

- Less likely to show dirt or wear compared to white.

- Cons:

- Poor contrast on dark solder masks, reducing visibility.

- Can slow down assembly if markings are hard to read.

- Slightly higher risk of application defects during manufacturing.

Factors to Consider When Choosing Silkscreen Color

Now that we’ve covered the differences, pros, and cons, here are some practical factors to keep in mind when deciding between black and white silkscreen for your PCB.

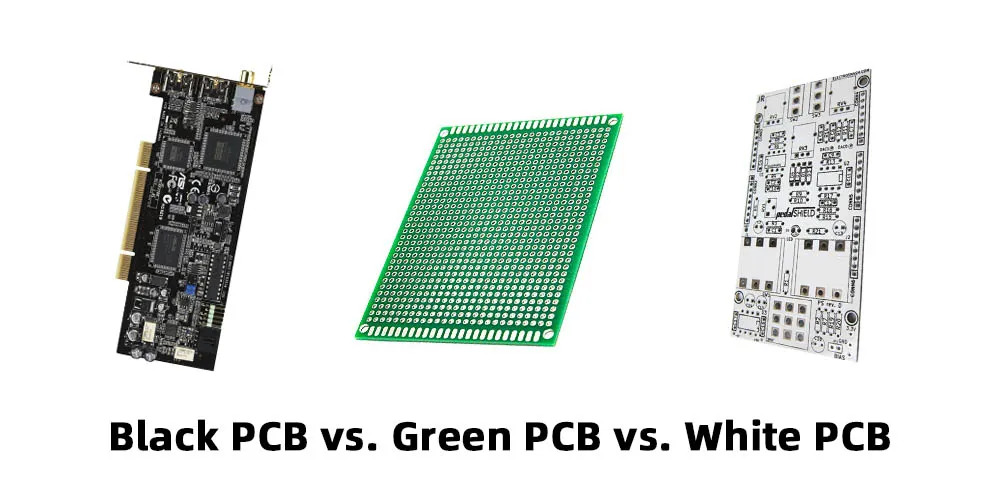

1. Solder Mask Color

The color of your solder mask is the most significant factor in determining silkscreen visibility. As a general rule, choose a silkscreen color that contrasts with your solder mask. For instance, if you’re using a green or black solder mask, white silkscreen is usually the better choice. If you have a white or yellow solder mask, black silkscreen will stand out more effectively.

2. Assembly Environment

Consider the lighting conditions in the environment where your PCB will be assembled or repaired. In dimly lit settings, high-contrast silkscreen colors are essential for quick and accurate work. White silkscreen often performs better in these scenarios, especially on darker backgrounds.

3. Cost and Availability

Both black and white silkscreen inks are standard options in PCB manufacturing, and the cost difference is usually negligible. However, some specialized manufacturers may charge slightly more for black silkscreen due to the need for precise application. Always confirm with your manufacturing partner if there are any additional fees.

4. Design and Branding Needs

If your PCB will be visible in a final product or used for marketing purposes, consider how the silkscreen color aligns with your brand's aesthetic. A well-chosen silkscreen color can enhance the overall look of your design and make a positive impression.

Best Practices for Silkscreen Design

Regardless of whether you choose black or white silkscreen, following best practices during the design phase can ensure optimal results in manufacturing and assembly.

- Use Clear, Legible Fonts: Choose fonts with a minimum height of 0.8 mm to ensure readability. Avoid overly complex or thin fonts that may not print clearly.

- Minimize Clutter: Only include essential information on the silkscreen layer, such as component identifiers, polarity markers, and critical warnings. Too much text can make the board look crowded and hard to read.

- Position Markings Strategically: Place labels close to the relevant components or pins without overlapping solder pads or vias, as this can cause issues during manufacturing.

- Test for Contrast: Before finalizing your design, preview how the silkscreen color looks against the solder mask in your design software. This can help you catch visibility issues early.

Conclusion: Which Silkscreen Color is Best for Your PCB?

Choosing between black and white silkscreen for your PCB depends on several factors, including the solder mask color, assembly environment, and design goals. White silkscreen is often the preferred choice due to its superior visibility on darker solder masks, which are the most common in the industry. It supports faster assembly and easier troubleshooting, making it a practical option for most projects. On the other hand, black silkscreen can be an excellent choice for lighter solder masks or when a specific aesthetic is desired, though it may pose visibility challenges in some cases.

Ultimately, the decision should prioritize functionality over appearance, especially for projects where assembly accuracy and speed are critical. By considering the contrast, environment, and manufacturing requirements, you can select the silkscreen color that best meets your needs.

At ALLPCB, we're committed to helping you achieve the best results for your PCB projects. Whether you opt for black or white silkscreen, our team is ready to support you through every step of the design and manufacturing process. Make sure to evaluate your specific requirements and choose the option that enhances both the performance and look of your PCB.

ALLPCB

ALLPCB