In-circuit testing (ICT) plays a critical role in ensuring PCB reliability, especially for applications in harsh environments where extreme temperatures, vibrations, and other stressors can lead to failures. By identifying defects early in the manufacturing process, ICT helps guarantee that printed circuit boards (PCBs) can withstand challenging conditions like those found in automotive, aerospace, and industrial settings. In this blog, we’ll dive deep into how ICT contributes to PCB reliability testing, its importance in extreme temperature testing and vibration testing, and its connection to protective measures like conformal coating inspection.

What Is In-Circuit Testing and Why Does It Matter?

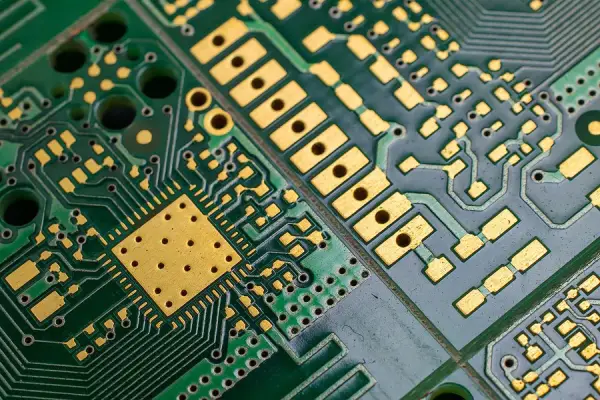

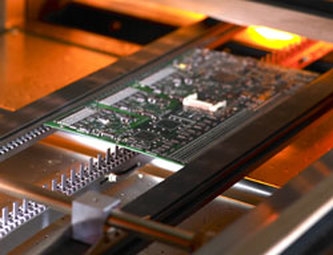

In-circuit testing is a method used during PCB manufacturing to check for defects in components and connections without powering up the board. It uses a specialized test fixture with probes that make contact with specific test points on the PCB to measure electrical properties like resistance, capacitance, and continuity. This process ensures that each component is correctly placed and functioning as intended before the board moves to final assembly or deployment.

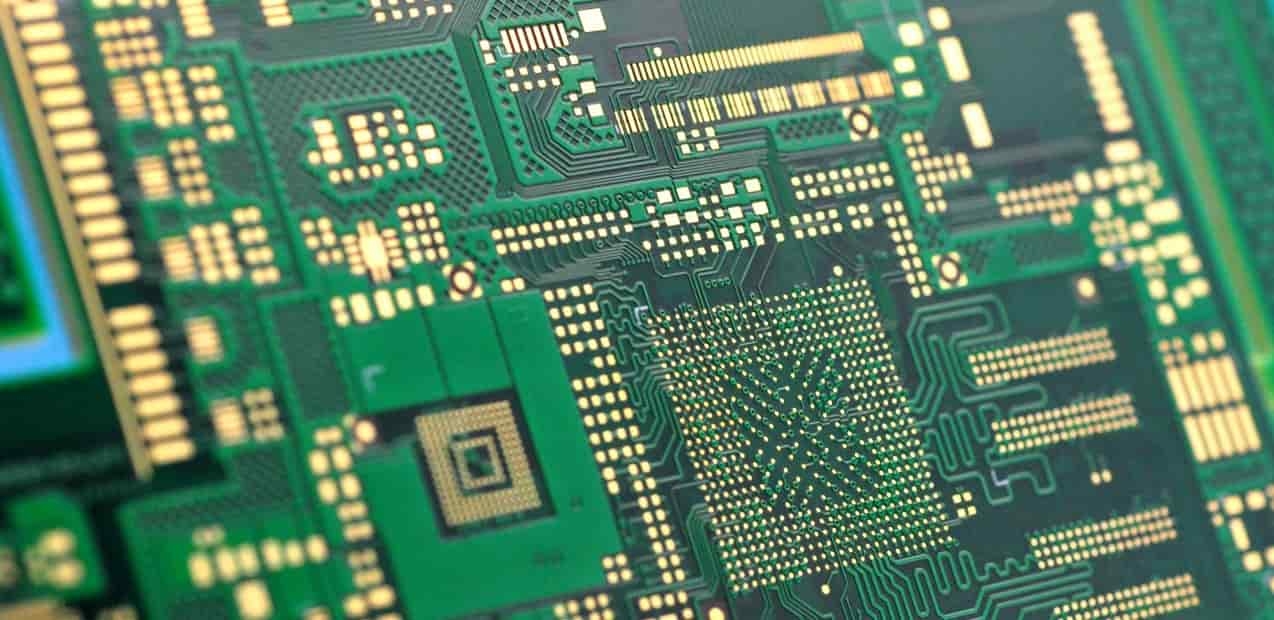

For PCBs destined for harsh environments, ICT is a vital step. These environments expose boards to stressors like temperature swings from -40°C to 85°C, intense vibrations up to 20G, and corrosive elements. A single faulty connection or misplaced component can lead to catastrophic failure in such conditions. ICT helps catch issues like short circuits, open circuits, or incorrect component values early, reducing the risk of failure in the field.

PCB Reliability Testing: The Foundation of Durability in Harsh Environments

PCB reliability testing is a comprehensive process that evaluates how well a board can perform under real-world conditions over time. It includes a range of tests designed to simulate the stresses a PCB might face, such as thermal cycling, humidity exposure, and mechanical shock. The goal is to ensure the board maintains functionality and integrity, especially in harsh environments where failure is not an option.

ICT serves as the first line of defense in this process. By verifying that every component and connection meets design specifications, ICT reduces the likelihood of defects that could compromise reliability during subsequent environmental tests. For example, a resistor with an incorrect value might not fail immediately but could overheat and degrade during extreme temperature testing. ICT catches such issues before they escalate.

Key Metrics in PCB Reliability Testing

During reliability testing, engineers focus on measurable parameters to assess a PCB’s performance. Some key metrics include:

- Thermal Resistance: Ensures the board can handle temperature changes without delamination or solder joint failure. For instance, a typical test might cycle between -40°C and 125°C for 1,000 cycles.

- Dielectric Strength: Measures the board’s ability to withstand high voltages without breakdown, often tested at 1,000V or more.

- Signal Integrity: Ensures signals remain clear and undistorted under stress, with acceptable impedance levels (e.g., 50 ohms for high-speed designs).

ICT contributes by ensuring the baseline electrical performance is correct before these rigorous tests begin, saving time and resources in the long run.

ICT for Harsh Environments: Building Confidence Under Stress

Harsh environments demand PCBs that can endure conditions far beyond typical consumer electronics. Think of a control board in a military vehicle operating in desert heat above 50°C or an industrial sensor in a factory exposed to constant vibrations. ICT for harsh environments focuses on validating the board’s ability to function under these extreme conditions by catching potential weak points early.

During ICT, engineers test for issues that might not be apparent in normal conditions but could fail under stress. For instance, a solder joint with poor contact might pass a basic continuity test but fail under vibration or thermal expansion. ICT can detect marginal connections by measuring resistance values—say, identifying a joint with 0.5 ohms of resistance instead of the expected 0.1 ohms—allowing for rework before the board faces real-world challenges.

Extreme Temperature Testing: How ICT Prepares PCBs for the Heat and Cold

Extreme temperature testing is a cornerstone of reliability testing for PCBs used in harsh environments. This process involves exposing the board to rapid temperature changes to simulate conditions like those in aerospace applications, where a system might go from freezing altitudes to intense heat during operation. Temperature swings can cause materials to expand and contract, stressing solder joints and components.

ICT plays a crucial role by ensuring the board starts with no underlying defects. For example, a capacitor with an incorrect rating might not fail at room temperature but could leak or burst at 100°C. ICT verifies component values and placements, ensuring they match the design’s thermal tolerance specifications. A typical test might confirm a capacitor’s rating at 16V with a tolerance of ±10%, preventing mismatches that could lead to failure.

Moreover, ICT data can guide engineers in selecting components with appropriate temperature ratings. By identifying weak points early, manufacturers can opt for high-grade components that withstand cycles from -55°C to 125°C, as often required in automotive standards like AEC-Q100.

Vibration Testing: Ensuring Stability with ICT Support

Vibration testing evaluates a PCB’s ability to endure mechanical stress, such as the constant shaking in heavy machinery or the turbulence in aircraft. Vibrations can loosen components, crack solder joints, or cause connectors to fail. Standards like MIL-STD-810 often define vibration profiles, with tests simulating forces up to 20G or frequencies from 10 Hz to 2,000 Hz.

ICT supports vibration testing by ensuring the board’s assembly is flawless before it undergoes such stress. A poorly soldered component might pass electrical tests at rest but detach under vibration. ICT checks for proper soldering by measuring continuity and resistance across joints, flagging any anomalies. For instance, a resistance spike from 0.2 ohms to 2 ohms at a solder point could indicate a weak bond likely to fail under 15G vibration.

By addressing these issues upfront, ICT minimizes the risk of mechanical failure, ensuring the PCB remains stable even when subjected to intense shaking or shock.

Conformal Coating Inspection: Protecting PCBs with ICT as a Precursor

Conformal coating is a protective layer applied to PCBs to shield them from moisture, dust, chemicals, and thermal shock. Common materials include acrylic, silicone, and urethane, each offering different levels of protection. For PCBs in harsh environments, conformal coating is often a non-negotiable step to ensure long-term reliability.

However, a conformal coating is only effective if the underlying PCB is free of defects. That’s where ICT comes in. Before applying the coating, ICT ensures there are no short circuits, open connections, or misplaced components that could cause issues later. A defect hidden under a coating is much harder to diagnose and repair, potentially leading to field failures.

Conformal coating inspection, often done visually or with automated optical systems, checks for uniform coverage and thickness (typically 25-75 micrometers). ICT complements this by providing a pre-coating assurance that the board’s electrical integrity is intact. For example, ICT can confirm that a critical ground connection has a resistance of less than 0.1 ohms, ensuring no faults are sealed under the coating.

How ICT Integrates with Other Reliability Testing Methods

While ICT is a powerful tool, it’s just one part of a broader reliability testing strategy. It works hand-in-hand with other methods to ensure PCBs can handle harsh environments. Here’s how ICT integrates with key testing approaches:

- Functional Testing: After ICT verifies individual components, functional testing powers up the board to check overall performance under simulated conditions, such as a 50°C operating environment.

- Environmental Stress Screening (ESS): ESS combines temperature, humidity, and vibration to weed out weak boards. ICT ensures no latent defects exist before ESS begins, reducing false failures.

- Highly Accelerated Life Testing (HALT): HALT pushes boards beyond their limits to find failure points. ICT provides a reliable starting point by confirming the board’s baseline quality.

This integrated approach ensures that PCBs are thoroughly vetted at every stage, from component-level checks to system-level stress tests, maximizing reliability in extreme conditions.

Best Practices for Implementing ICT in PCB Manufacturing

To get the most out of ICT for harsh environment applications, manufacturers should follow these best practices:

- Design for Testability (DFT): Include accessible test points in the PCB layout to allow ICT probes to reach critical nodes. This might mean spacing components to avoid interference with probes.

- Comprehensive Test Coverage: Develop ICT programs that check at least 90% of components and connections, focusing on high-risk areas like power lines and high-speed signals.

- Regular Calibration: Ensure ICT equipment is calibrated to maintain accuracy, especially for resistance measurements as low as 0.01 ohms.

- Data Analysis: Use ICT data to identify recurring defects and improve manufacturing processes, such as adjusting soldering temperatures or component placement accuracy.

By adhering to these practices, manufacturers can enhance the effectiveness of ICT, leading to more reliable PCBs for demanding applications.

Conclusion: ICT as the Backbone of PCB Reliability in Harsh Environments

In-circuit testing is an indispensable part of ensuring PCB reliability, particularly for applications in harsh environments. By catching defects early, ICT lays the groundwork for successful extreme temperature testing, vibration testing, and conformal coating inspection. It ensures that every component and connection is up to standard, reducing the risk of failure when the board faces intense heat, cold, or mechanical stress.

For engineers and manufacturers, investing in robust ICT processes is a proactive step toward building durable, high-performance PCBs. Whether it’s a control system in a rugged industrial setting or a sensor in an aerospace application, ICT provides the confidence that the board will perform as expected, no matter the conditions. With the right testing strategy, including ICT as a core component, reliability becomes not just a goal but a guarantee.

ALLPCB

ALLPCB