When it comes to designing a printed circuit board (PCB) for your electronic project, one of the first decisions you’ll face is whether to go with a single-sided or double-sided assembly. Both options have their unique strengths and limitations, and the right choice depends on your project’s complexity, budget, and performance needs. In this comprehensive guide, we’ll break down the key differences between single-sided PCB vs double-sided PCB, compare single layer vs double layer PCB designs, and explore the benefits of single-sided assembly and the advantages of double-sided assembly. By the end, you’ll have a clear understanding of which option suits your project best.

What Are Single-Sided and Double-Sided PCBs?

Before diving into the details, let’s clarify the basics. A single-sided PCB has conductive traces and components on only one side of the board. The other side is typically left bare or used for labeling. In contrast, a double-sided PCB features conductive traces and components on both sides, allowing for more complex circuits and higher component density.

Understanding the distinction between single layer vs double layer PCB designs is critical because it impacts the functionality, cost, and manufacturing process of your project. Let’s explore each type in depth to help you make an informed decision.

Single-Sided PCB: Features and Design

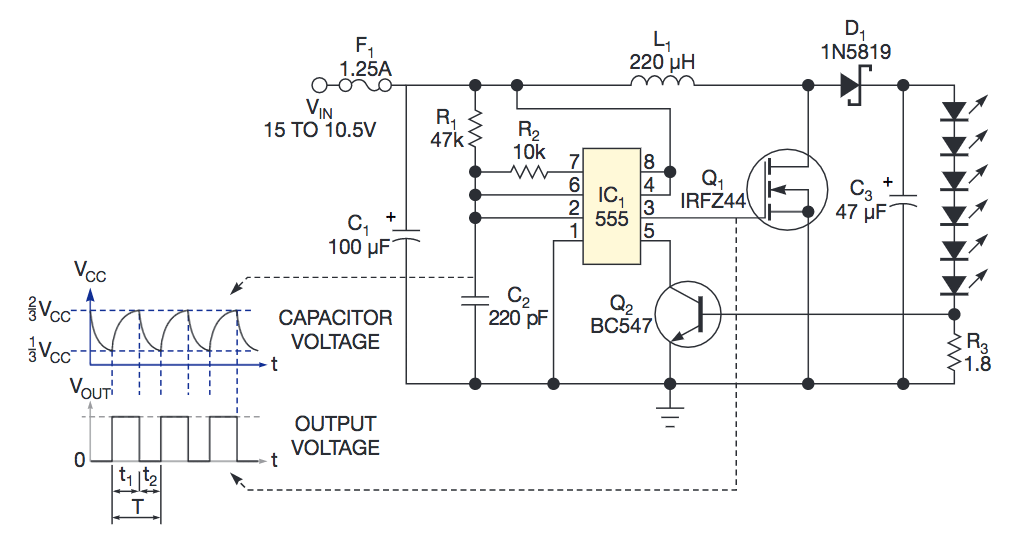

Single-sided PCBs are the simplest type of circuit board, consisting of a single layer of conductive material, usually copper, on one side of a non-conductive substrate like FR-4 (a fiberglass-epoxy composite). Components are mounted on this side, and the traces connect them to form the circuit.

These boards are ideal for basic electronics with low component density and straightforward designs. Common applications include power supplies, LED lighting, and simple consumer devices like calculators or remote controls. The manufacturing process for single-sided assembly is relatively easy, as it involves fewer steps compared to double-sided boards.

Single-Sided Assembly Benefits

Choosing a single-sided PCB offers several practical advantages, especially for beginners or projects with tight budgets. Here are the key benefits:

- Cost-Effective: Single-sided PCBs are cheaper to produce because they require less material and simpler manufacturing processes. For high-volume production, this cost difference can add up significantly.

- Simpler Design: With only one layer to work with, the design process is less complex. This makes it easier for hobbyists or small-scale projects to prototype and test ideas quickly.

- Faster Production: Since there’s no need to align or connect layers on both sides, single-sided assembly often has shorter lead times in manufacturing.

- Lower Risk of Errors: With fewer layers and connections, there’s a reduced chance of manufacturing defects like misaligned vias or interlayer connectivity issues.

However, single-sided PCBs have limitations. They can’t handle high-density designs or complex circuits because there’s limited space for traces and components. If your project requires crossing traces, you’ll need to use jumpers, which can clutter the board and increase the risk of errors.

Double-Sided PCB: Features and Design

Double-sided PCBs take things a step further by allowing conductive traces and components on both sides of the board. Small holes called vias connect the traces between the top and bottom layers, enabling more intricate routing and higher component density. This design is often used in more advanced electronics, such as smartphones, automotive systems, and industrial equipment.

The added layer in a double-sided PCB provides greater flexibility for circuit design. You can place more components in a smaller footprint, making it a go-to choice for compact devices. However, the manufacturing process is more complex, as it requires precise alignment of the layers and drilling of vias.

Double-Sided Assembly Advantages

Opting for a double-sided PCB brings several benefits, especially for projects that demand higher performance or miniaturization. Let’s look at the main advantages:

- Higher Component Density: With traces and components on both sides, you can fit more functionality into a smaller space. This is essential for modern devices where size is a critical factor.

- Improved Circuit Complexity: Double-sided boards support more complex circuits without the need for external jumpers. Vias allow traces to cross over each other seamlessly, reducing clutter.

- Better Signal Integrity: By carefully routing traces on both sides, you can minimize interference and crosstalk, which is crucial for high-speed applications. For instance, in a double-sided design, you might achieve impedance values around 50 ohms for controlled signal paths, compared to less predictable values on single-sided boards.

- Enhanced Durability: The ability to distribute components and traces across two sides can reduce stress on individual layers, potentially improving the board’s longevity in demanding environments.

Despite these advantages, double-sided PCBs come with challenges. They are more expensive to manufacture due to the additional materials and precision required. The design process is also more time-consuming, as engineers must ensure proper alignment and connectivity between layers.

Single Layer vs Double Layer PCB: A Direct Comparison

To help you choose between single layer vs double layer PCB designs, let’s compare them across several key factors. This side-by-side analysis will give you a clearer picture of how they stack up for your specific needs.

| Factor | Single-Sided PCB | Double-Sided PCB |

|---|---|---|

| Cost | Lower cost due to simpler design and fewer materials. | Higher cost due to added materials and manufacturing complexity. |

| Design Complexity | Simple, suitable for basic circuits with fewer components. | Supports complex circuits with higher component density. |

| Space Efficiency | Limited space; larger board size may be needed for more components. | More efficient; allows for compact designs with more components. |

| Signal Performance | Prone to interference and crosstalk in high-speed applications. | Better signal integrity with controlled impedance (e.g., 50 ohms) and reduced interference. |

| Manufacturing Time | Faster production with fewer steps. | Slower production due to layer alignment and via drilling. |

| Applications | Basic electronics like LED lights, calculators, and power supplies. | Advanced devices like smartphones, automotive systems, and medical equipment. |

This comparison highlights that single-sided PCBs are best for straightforward, cost-sensitive projects, while double-sided PCBs excel in applications requiring compactness and complexity.

When to Choose Single-Sided Assembly

Single-sided assembly is the right choice for projects where simplicity and cost are top priorities. Here are some scenarios where a single-sided PCB makes sense:

- Low-Cost Prototyping: If you’re in the early stages of development and need to test a basic concept, a single-sided board keeps expenses low.

- Simple Circuits: For designs with minimal components and no need for trace crossovers, a single layer is sufficient. Think of a basic LED driver circuit with fewer than 10 components.

- Bulk Production of Basic Devices: In mass production of low-complexity products like toys or small appliances, the cost savings of single-sided assembly can be significant.

- Educational Projects: Students or hobbyists learning electronics often start with single-sided boards due to their simplicity and ease of soldering.

Keep in mind that as your project grows in complexity—say, requiring more than 20 components or high-speed signals above 100 MHz—you may outgrow the capabilities of a single-sided design.

When to Choose Double-Sided Assembly

Double-sided assembly shines in projects where performance, space, and functionality take precedence over cost. Consider a double-sided PCB in these situations:

- Compact Designs: If your device needs to fit into a small enclosure, such as a wearable gadget, a double-sided board allows you to pack more components into a limited area.

- High-Speed Applications: For circuits handling data rates above 100 Mbps or sensitive analog signals, double-sided designs offer better trace routing to minimize noise and maintain impedance control.

- Complex Functionality: Projects with multiple integrated circuits, sensors, and connectors often require the additional routing options that double-sided boards provide.

- Professional Products: In commercial or industrial applications, where reliability and performance are critical, double-sided PCBs are often the standard choice.

While the upfront cost is higher, the benefits of double-sided assembly often outweigh the expense in demanding applications.

Key Factors to Consider When Choosing Between Single-Sided and Double-Sided PCBs

Making the right choice between single-sided PCB vs double-sided PCB involves weighing several factors specific to your project. Here are the most important considerations:

- Budget Constraints: Determine how much you’re willing to spend on PCB manufacturing. If cost is a major concern, single-sided assembly might be the better option.

- Circuit Complexity: Assess the number of components and connections. A circuit with over 15-20 components or requiring multiple crossovers often benefits from a double-sided design.

- Size Requirements: If your project demands a small form factor, a double-sided PCB can help reduce the board’s footprint.

- Performance Needs: Evaluate signal speed and integrity requirements. High-frequency designs (above 100 MHz) or those needing precise impedance matching (e.g., 50 ohms) are better suited to double-sided boards.

- Production Volume: For low-volume prototypes, single-sided boards may save money. For high-volume production of complex devices, the per-unit cost difference for double-sided boards becomes less significant.

By carefully analyzing these factors, you can align your choice with both technical and financial goals.

Manufacturing Considerations for Single-Sided and Double-Sided Assembly

The manufacturing process for single-sided and double-sided PCBs differs significantly, and understanding these differences can influence your decision. Single-sided assembly involves fewer steps: the design is etched onto one side, components are placed, and soldering is completed. This simplicity translates to lower costs and faster turnaround times, often by 20-30% compared to double-sided boards.

Double-sided assembly, on the other hand, requires additional steps like drilling vias, plating through-holes, and ensuring alignment between layers. These processes increase production time and cost by approximately 30-50% compared to single-sided boards, depending on the complexity. However, advancements in manufacturing technology have made double-sided assembly more accessible, even for smaller runs.

Another aspect to consider is testing and quality control. Double-sided boards often undergo more rigorous testing to check for issues like via connectivity or layer misalignment, which can add to lead times but ensure higher reliability.

Conclusion: Making the Right Choice for Your Project

Deciding between single-sided vs double-sided assembly comes down to balancing cost, complexity, and performance. Single-sided PCBs offer unmatched simplicity and affordability, making them ideal for basic projects or cost-sensitive applications. Their benefits include lower production costs and faster manufacturing times, perfect for straightforward designs.

Double-sided PCBs, however, provide superior flexibility with higher component density and better signal performance, catering to compact and complex devices. The advantages of double-sided assembly, such as improved circuit routing and space efficiency, often justify the higher cost in professional or high-speed applications.

Whether you’re comparing single layer vs double layer PCB options or weighing single-sided assembly benefits against double-sided assembly advantages, the key is to align your choice with your project’s specific needs. Evaluate your budget, design requirements, and performance goals to select the PCB type that will bring your vision to life efficiently and effectively.

At ALLPCB, we’re committed to supporting your journey with high-quality PCB solutions tailored to your unique requirements. Whether you opt for a single-sided or double-sided design, our expertise ensures your project achieves optimal results.

ALLPCB

ALLPCB