Are you looking to design a high-efficiency LED driver circuit that maximizes performance while minimizing power loss? In this comprehensive guide, we’ll walk you through actionable tips and tricks to optimize your LED circuits. From understanding LED forward voltage optimization to reducing power loss in LED circuits, increasing LED lifespan, and maximizing LED lumen output, we’ve got you covered with practical advice for engineers.

Whether you're working on lighting solutions for commercial, industrial, or personal projects, efficiency is key to achieving cost savings and sustainability. Let’s dive into the details of designing circuits that deliver top-notch performance for your LED applications.

Why High-Efficiency LED Driver Circuits Matter

LEDs (Light Emitting Diodes) have revolutionized lighting with their low energy consumption, long lifespan, and bright output. However, without a properly designed driver circuit, you risk wasting energy, reducing the lifespan of your LEDs, or failing to achieve the desired brightness. A high-efficiency LED driver circuit ensures that the LEDs receive the right current and voltage, minimizing energy loss and heat generation.

For engineers, focusing on efficiency isn’t just about saving power—it’s about creating reliable, long-lasting systems. Efficient circuits lead to cooler operation, which directly impacts the longevity of components. Let’s explore how to achieve this with proven design strategies.

Understanding the Basics of LED Driver Circuits

Before diving into advanced tips, let’s cover the fundamentals. An LED driver circuit regulates the power supplied to an LED or a string of LEDs. Unlike traditional bulbs, LEDs require a constant current to operate efficiently. If the current fluctuates or exceeds the LED’s rating, it can overheat and fail prematurely.

There are two main types of LED drivers: constant current and constant voltage. Constant current drivers are more common for high-power LEDs because they maintain a steady current regardless of voltage changes. Constant voltage drivers, on the other hand, are often used for LED strips where multiple LEDs are connected in parallel.

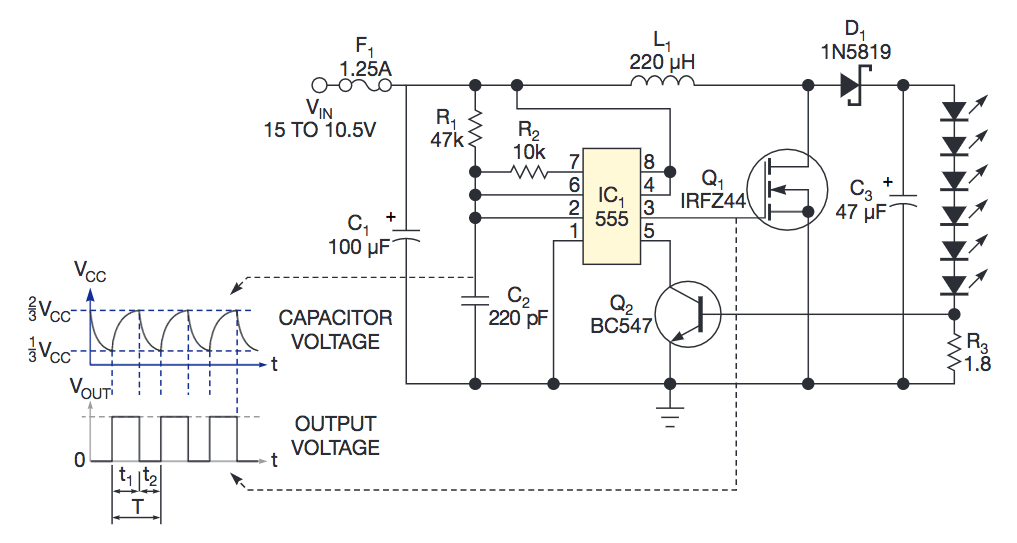

For a high-efficiency LED driver circuit, choosing the right topology—such as buck, boost, or buck-boost—depends on your input voltage and the LED’s forward voltage. For instance, if your input voltage is lower than the LED string’s total forward voltage (e.g., a 12V battery powering a 24V LED string), a boost converter is necessary to step up the voltage.

Tip 1: Focus on LED Forward Voltage Optimization

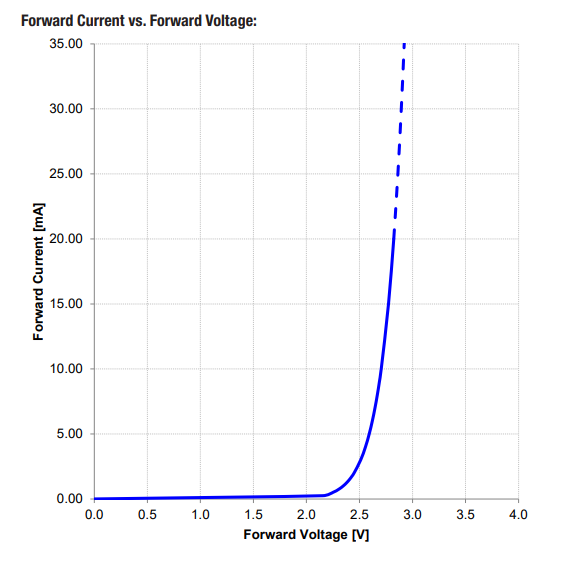

One of the first steps in designing an efficient LED circuit is LED forward voltage optimization. The forward voltage is the voltage drop across an LED when it’s conducting current. This value varies depending on the LED type and manufacturer, typically ranging from 1.8V for red LEDs to 3.6V for white or blue LEDs.

To optimize, match the driver’s output voltage as closely as possible to the total forward voltage of your LED string. For example, if you’re using six white LEDs with a forward voltage of 3.2V each, the total forward voltage is 19.2V. Using a driver that outputs exactly or slightly above this value reduces excess voltage that would otherwise be dissipated as heat.

Additionally, check the LED datasheet for the recommended operating current. Running an LED at a lower current than its maximum rating can slightly reduce the forward voltage, further improving efficiency. However, ensure this doesn’t compromise the desired brightness or lumen output.

Tip 2: Reducing Power Loss in LED Circuits

Power loss is a major concern when designing LED circuits, as it directly affects efficiency and generates unwanted heat. Reducing power loss in LED circuits starts with minimizing resistive losses and choosing the right components.

First, use low-resistance components in your circuit, especially in high-current paths. For example, select MOSFETs with low RDS(on) values (e.g., below 50 mΩ) for switching applications in your driver circuit. This reduces the voltage drop and heat generated during operation.

Second, consider the efficiency of your driver topology. Switching regulators like buck or boost converters typically achieve efficiencies of 85-95%, compared to linear regulators, which can drop to 50% or lower when there’s a large difference between input and output voltage. For instance, a buck converter operating at 90% efficiency with a 24V input and 12V output will only lose 1.2W of power for every 12W delivered to the LEDs.

Lastly, avoid over-sizing components. Using a capacitor or inductor with excessive ratings can introduce parasitic losses. Always calculate the required values based on your circuit’s ripple current and switching frequency. Online tools or simulation software can help with these calculations.

Tip 3: Increasing LED Lifespan Through Thermal Management

Heat is the enemy of LED longevity. Increasing LED lifespan starts with managing the thermal performance of your circuit. High temperatures can degrade the LED’s phosphor coating, reduce lumen output, and shorten its operational life from 50,000 hours to just a few thousand.

To combat this, ensure your driver circuit operates efficiently to minimize heat generation. As mentioned earlier, reducing power loss directly lowers the heat produced. Additionally, incorporate proper heat sinking for both the LEDs and driver components. For high-power LEDs (e.g., 3W or more), mount them on a metal-core PCB or aluminum heat sink to dissipate heat effectively.

Another strategy is to implement temperature compensation in your driver circuit. Some advanced driver ICs reduce current output when the temperature exceeds a certain threshold (e.g., 85°C). This prevents overheating and extends the LED’s life without sacrificing too much brightness.

Tip 4: Maximizing LED Lumen Output Without Sacrificing Efficiency

Maximizing LED lumen output is often a balancing act with efficiency. Lumen output refers to the brightness of the LED, and while increasing current can boost brightness, it also increases heat and power consumption, reducing overall efficiency.

To achieve high lumen output efficiently, select LEDs with a high luminous efficacy, measured in lumens per watt (lm/W). Modern high-power LEDs can achieve 100-150 lm/W or more. For example, a 3W LED with 120 lm/W produces 360 lumens, while an older model at 80 lm/W only produces 240 lumens for the same power.

Next, design your driver circuit to operate the LEDs at their optimal current for maximum efficacy. Many LEDs have a “sweet spot” where lumen output per watt is highest—often below the maximum rated current. Check the manufacturer’s efficacy curve to find this point. For instance, a 1W LED might achieve peak efficacy at 300mA rather than its maximum 350mA.

Finally, use optics or reflectors to focus the light output where it’s needed. This doesn’t increase the raw lumen output but ensures more light reaches the intended area, effectively improving perceived brightness without additional power.

Tip 5: Choosing the Right Components for Your LED Driver Circuit

Component selection plays a critical role in the efficiency of your LED driver circuit. Start with the driver IC or controller. Look for ICs with high switching frequencies (e.g., 500 kHz to 1 MHz) as they allow the use of smaller inductors and capacitors, reducing board space and losses. However, be cautious—higher frequencies can increase switching losses, so balance this with your design needs.

For inductors, choose ones with low DC resistance (DCR) and high saturation current ratings to handle peak currents without significant losses. A typical value for a boost converter might be a 10 μH inductor with a DCR of 0.05 ohms or less.

Capacitors should have low equivalent series resistance (ESR) to minimize ripple and heat. Ceramic capacitors are often preferred over electrolytic ones for their lower ESR and longer lifespan, especially in high-frequency switching circuits.

Lastly, consider dimming capabilities if your application requires it. Many modern driver ICs support pulse-width modulation (PWM) dimming, which adjusts brightness without affecting color temperature or efficiency as much as analog dimming.

Tip 6: Simulation and Testing for Optimal Performance

Before finalizing your design, simulate your circuit using software tools to identify potential inefficiencies. Simulation helps you analyze parameters like ripple current, voltage drops, and thermal performance under different conditions.

Once the circuit is built, test it with real-world conditions. Measure the input and output power to calculate efficiency (efficiency = output power / input power x 100%). For example, if your driver supplies 10W to the LEDs but draws 11.5W from the source, the efficiency is approximately 87%. If it’s lower than expected, revisit your component choices or topology.

Also, test for thermal performance using a thermal camera or temperature probes. Ensure no component exceeds its rated temperature, typically 85-105°C for most ICs and LEDs.

Common Pitfalls to Avoid in LED Circuit Design

Even experienced engineers can make mistakes when designing LED circuits. One common error is underestimating the importance of current regulation. Without proper current control, LEDs can experience thermal runaway, where increased heat lowers resistance, drawing more current and creating a destructive cycle.

Another pitfall is ignoring input voltage variations. If your power source fluctuates (e.g., a battery dropping from 12V to 10V as it discharges), ensure your driver can handle the range without compromising LED performance.

Lastly, don’t skip proper PCB layout. Poor grounding or long traces in high-current paths can introduce noise and losses. Keep power loops short and place decoupling capacitors close to the driver IC for optimal performance.

Conclusion: Building Better LED Circuits for the Future

Designing a high-efficiency LED driver circuit is a blend of science and strategy. By focusing on LED forward voltage optimization, reducing power loss in LED circuits, increasing LED lifespan, and maximizing LED lumen output, you can create systems that are both powerful and sustainable. Remember to choose the right components, simulate and test your designs, and avoid common pitfalls to ensure success.

With these tips and tricks, you’re well-equipped to tackle your next LED project with confidence. Efficiency isn’t just a goal—it’s a necessity for modern lighting solutions. Start implementing these strategies today to build circuits that shine brighter and last longer.

ALLPCB

ALLPCB