In the fast-paced world of electronics manufacturing, electrostatic discharge (ESD) poses a significant threat to the integrity of sensitive components, especially in automated assembly processes. While wrist straps are a common tool for ESD control in manual settings, they fall short in high-speed, robotic, and automated environments like SMT (Surface Mount Technology) lines. So, how can manufacturers ensure comprehensive ESD control in automated assembly? The answer lies in a multi-layered approach that integrates advanced equipment, proper facility design, and strict protocols to protect components during robotic assembly ESD challenges and beyond.

In this blog post, we’ll dive deep into the strategies for ESD protection in SMT lines, explore methods for minimizing ESD in high-speed assembly, and outline effective solutions for automated PCB handling ESD risks. Whether you’re managing a fully automated production line or integrating robotics into your workflow, these insights will help safeguard your products and boost reliability.

Why ESD Control Matters More in Automated Assembly

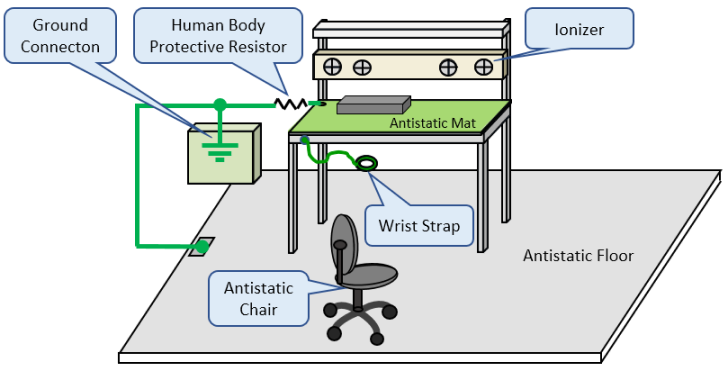

Electrostatic discharge occurs when static electricity builds up and suddenly transfers between two objects, often damaging delicate electronic components. In traditional manual assembly, workers wear wrist straps connected to grounding points to dissipate static charge. However, automated assembly processes—where machines, robots, and conveyors dominate—require a broader approach. Components in these settings are often handled at high speeds with minimal human intervention, increasing the risk of ESD damage if proper controls aren’t in place.

The stakes are high. A single ESD event can cause latent defects, reducing a device’s lifespan or leading to failures in the field. According to industry studies, ESD-related failures can account for up to 30% of electronic product defects, costing manufacturers millions annually in rework and warranty claims. In automated environments, where production rates can exceed thousands of units per hour, even a small percentage of failures translates to significant losses. This makes ESD control in automated assembly not just a quality concern but a financial imperative.

Challenges of ESD in Robotic and High-Speed Assembly

Automated assembly lines, particularly those using robotic systems and SMT technology, face unique ESD challenges. Here are some key issues:

- Friction from Moving Parts: Conveyors, robotic arms, and pick-and-place machines generate static electricity through friction as they move components at high speeds. For instance, a conveyor belt running at 2 meters per second can build up a static charge of several thousand volts if not properly grounded.

- Lack of Human Grounding: Unlike manual assembly, where wrist straps ground workers, machines and tools in robotic assembly ESD scenarios must be independently grounded or designed with static-dissipative materials.

- Smaller Components, Higher Sensitivity: Modern electronics often use components with geometries below 5 nanometers, making them extremely vulnerable to even minor ESD events—sometimes as low as 10 volts can cause damage.

- High Throughput: In high-speed assembly, thousands of components are handled per minute, amplifying the risk of undetected ESD damage across large batches.

Addressing these challenges requires a shift from basic ESD tools to a comprehensive system tailored for automation.

Key Strategies for ESD Protection in SMT Lines

SMT lines are the backbone of modern electronics manufacturing, and ESD protection in SMT lines is critical to maintaining yield and quality. Below are proven strategies to implement:

1. Grounding All Equipment

Every piece of equipment in an SMT line— from pick-and-place machines to reflow ovens—must be properly grounded. Grounding resistance should be regularly tested to ensure it remains below 1 ohm, as higher resistance can allow static buildup. Use conductive mats or flooring around equipment to create a static-safe zone, ensuring that any charge is safely dissipated.

2. Static-Dissipative Materials

Replace standard plastic or rubber components in machines with static-dissipative alternatives. For example, use trays, reels, and feeders made from materials with surface resistivity between 10^5 and 10^9 ohms per square. This prevents static charge accumulation during component handling.

3. Ionization Systems

In environments where grounding alone isn’t sufficient, air ionizers can neutralize static charges on components and surfaces. Place ionizers near critical areas like pick-and-place heads or conveyor entry points to maintain a charge-neutral environment. Ensure ionizers are calibrated to balance positive and negative ions, avoiding overcompensation that could introduce new static risks.

Minimizing ESD in High-Speed Assembly

Minimizing ESD in high-speed assembly requires a focus on both prevention and monitoring. The faster components move through a production line, the greater the potential for static buildup. Here’s how to tackle this:

1. Control Environmental Conditions

Static electricity thrives in dry environments. Maintain relative humidity between 40% and 60% in assembly areas to reduce static buildup. Use humidifiers if necessary, especially in climates with low natural humidity. Additionally, keep temperatures stable (around 20-25°C) to avoid conditions that exacerbate static generation.

2. High-Speed Equipment Design

Work with equipment manufacturers to ensure that high-speed machines are designed with ESD in mind. For instance, robotic arms should have conductive coatings or grounding straps, and conveyor belts should be made of antistatic materials. Regularly inspect these systems for wear, as degraded materials can lose their ESD-protective properties over time.

3. Real-Time Monitoring

Install ESD monitoring systems to detect static events in real time. These systems can alert operators to charge levels exceeding safe thresholds (e.g., above 100 volts) and pinpoint areas of concern. Continuous monitoring is especially vital in high-speed lines where manual checks are impractical.

Automated PCB Handling: ESD Strategies

Handling printed circuit boards (PCBs) in automated systems introduces specific risks, as boards often carry sensitive components during transit. Here are tailored strategies for automated PCB handling ESD protection:

1. ESD-Safe Packaging and Storage

Use antistatic bags or containers with surface resistivity in the range of 10^5 to 10^9 ohms per square for storing and transporting PCBs. Ensure that automated handling systems, such as robotic grippers or conveyor loaders, are compatible with these materials to avoid charge transfer during movement.

2. Conductive Fixtures and Tools

Automated systems often use fixtures to hold PCBs during assembly. Ensure these fixtures are made of conductive or dissipative materials and are properly grounded. For example, a fixture with a grounding resistance above 1 ohm could fail to dissipate static, risking component damage.

3. Minimize Contact Points

Design automated handling systems to reduce unnecessary contact between PCBs and machine parts. Each contact point is a potential source of static charge. Use vacuum or suction-based handling where possible, as these methods minimize physical friction compared to mechanical grippers.

Training and Protocols for ESD Control in Automation

While automation reduces human involvement, personnel still play a role in maintaining ESD-safe environments. Even in highly automated facilities, operators and maintenance staff must be trained on ESD principles. Develop protocols for handling components during machine setup, maintenance, or troubleshooting. Ensure that tools used by staff, such as screwdrivers or testers, are ESD-safe and regularly inspected.

Additionally, establish a regular audit schedule to verify that all ESD control measures—grounding, ionization, and environmental controls—are functioning as intended. Use checklists to confirm that equipment resistance, humidity levels, and ionizer performance meet industry standards, such as those set by the ANSI/ESD S20.20 guidelines.

Advanced Technologies for ESD Control

As automation in electronics manufacturing evolves, so do the technologies for ESD control. Here are some cutting-edge solutions to consider:

- Smart ESD Monitoring: IoT-enabled sensors can track static levels across an entire production floor, sending data to a central dashboard for real-time analysis. This allows for immediate corrective action if thresholds are breached.

- ESD-Safe Robotics: Some modern robotic systems are built with integrated static-dissipative materials and grounding mechanisms, reducing the need for external controls.

- Automated Testing Systems: Specialized equipment can test components for ESD damage at various stages of assembly, ensuring that only defect-free products move forward in the process.

Integrating these technologies can significantly enhance ESD control in automated assembly, providing a competitive edge in quality and reliability.

Building an ESD-Safe Culture in Automated Facilities

Effective ESD control goes beyond tools and technology—it requires a culture of awareness and accountability. Ensure that all team members, from engineers to technicians, understand the importance of ESD protection. Display clear signage in assembly areas to remind staff of ESD-safe practices, even in automated zones. Regularly update training programs to cover new equipment or processes, reinforcing the commitment to quality at every level.

Conclusion: A Holistic Approach to ESD Control

In the realm of automated assembly, relying solely on wrist straps or basic grounding is no longer enough. Comprehensive ESD control in automated assembly demands a combination of grounded equipment, static-dissipative materials, environmental controls, and advanced monitoring. By addressing the unique challenges of robotic assembly ESD, implementing robust ESD protection in SMT lines, focusing on minimizing ESD in high-speed assembly, and adopting strategies for automated PCB handling ESD, manufacturers can protect sensitive components and ensure product reliability.

At ALLPCB, we’re committed to supporting your manufacturing needs with solutions that prioritize quality and efficiency. By integrating these ESD control strategies into your automated processes, you can reduce defects, lower costs, and deliver electronics that stand the test of time. Start building a safer, smarter production line today with these actionable insights.

ALLPCB

ALLPCB