Conformal coating removal for SMT components is a critical yet delicate process in PCB rework and repair. Whether you're dealing with SMT pads, BGA chips, or other sensitive components, removing conformal coating requires precision to avoid damaging the board or its parts. In this comprehensive guide, we’ll walk you through the essentials of removing conformal coating from SMT pads, protecting SMT components during rework, and using precision conformal coating removal tools. You'll also learn about specific SMT rework techniques and best practices for handling conformal coating removal around BGA chips. Let’s dive into the details to ensure your rework process is safe and effective.

What Is Conformal Coating and Why Remove It?

Conformal coating is a thin protective layer applied to printed circuit boards (PCBs) to shield them from environmental hazards like moisture, dust, chemicals, and temperature extremes. This polymeric film enhances the reliability of electronic assemblies, especially in harsh conditions, by providing dielectric resistance and preventing corrosion. However, during PCB rework or repair, this protective layer often needs to be removed to access underlying components, such as SMT pads or BGA chips, for replacement or troubleshooting.

Removing conformal coating is no simple task. The process must be done with care to avoid damaging delicate SMT components or the PCB itself. Improper techniques can lead to issues like lifted pads, thermal damage, or compromised board integrity. Understanding the right methods and tools is essential for a successful operation.

Challenges of Conformal Coating Removal for SMT Components

SMT components, including tiny resistors, capacitors, and complex BGA chips, are densely packed on modern PCBs. Their small size and proximity to one another make conformal coating removal a challenging task. Here are some key challenges to consider:

- Precision Requirements: SMT pads and BGA chips have fine pitch and delicate structures. Removing coating without damaging these elements requires high accuracy.

- Thermal Sensitivity: Many SMT components are sensitive to heat. Excessive temperatures during removal can cause thermal stress or desoldering of nearby parts.

- Chemical Risks: Solvents used for coating removal can harm components or leave residues that affect performance if not cleaned properly.

- Electrostatic Discharge (ESD): The rework process can generate static electricity, risking damage to sensitive electronic components.

Given these challenges, it’s crucial to use the right techniques and tools tailored to the type of conformal coating and the specific components involved.

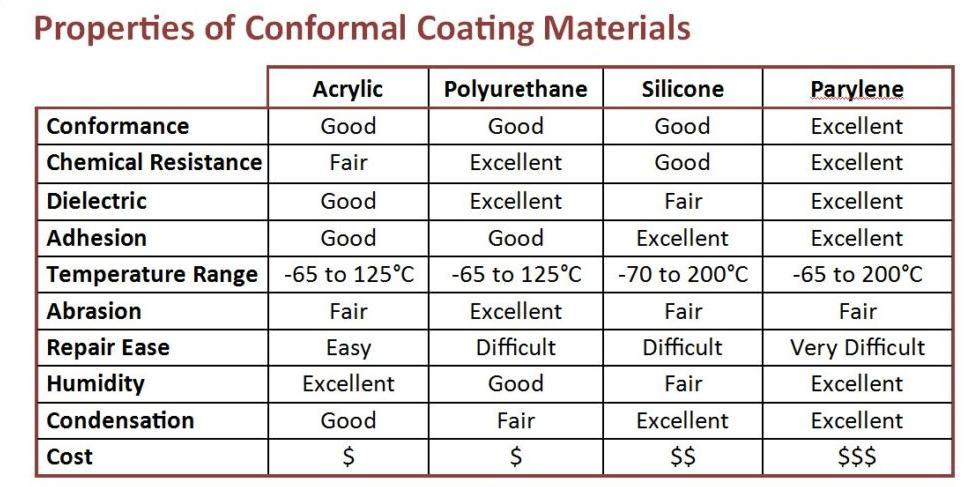

Types of Conformal Coatings and Their Impact on Removal

Before diving into removal techniques, it’s important to identify the type of conformal coating on your PCB, as different materials require different approaches. Common types include:

- Acrylic: Easy to remove with solvents but can be brittle and prone to cracking during mechanical removal.

- Silicone: Flexible and heat-resistant, often requiring specialized solvents or mechanical methods for removal.

- Urethane: Tough and durable, typically needing aggressive solvents or abrasion techniques.

- Parylene: Extremely thin and conformal, often requiring micro-abrasion or plasma etching for removal due to its resistance to solvents.

Identifying the coating type helps in selecting the most effective removal method while minimizing risks to SMT components and BGA chips. If the coating type is unknown, consult the PCB documentation or perform a small test in an inconspicuous area to determine the best approach.

Techniques for Removing Conformal Coating from SMT Pads

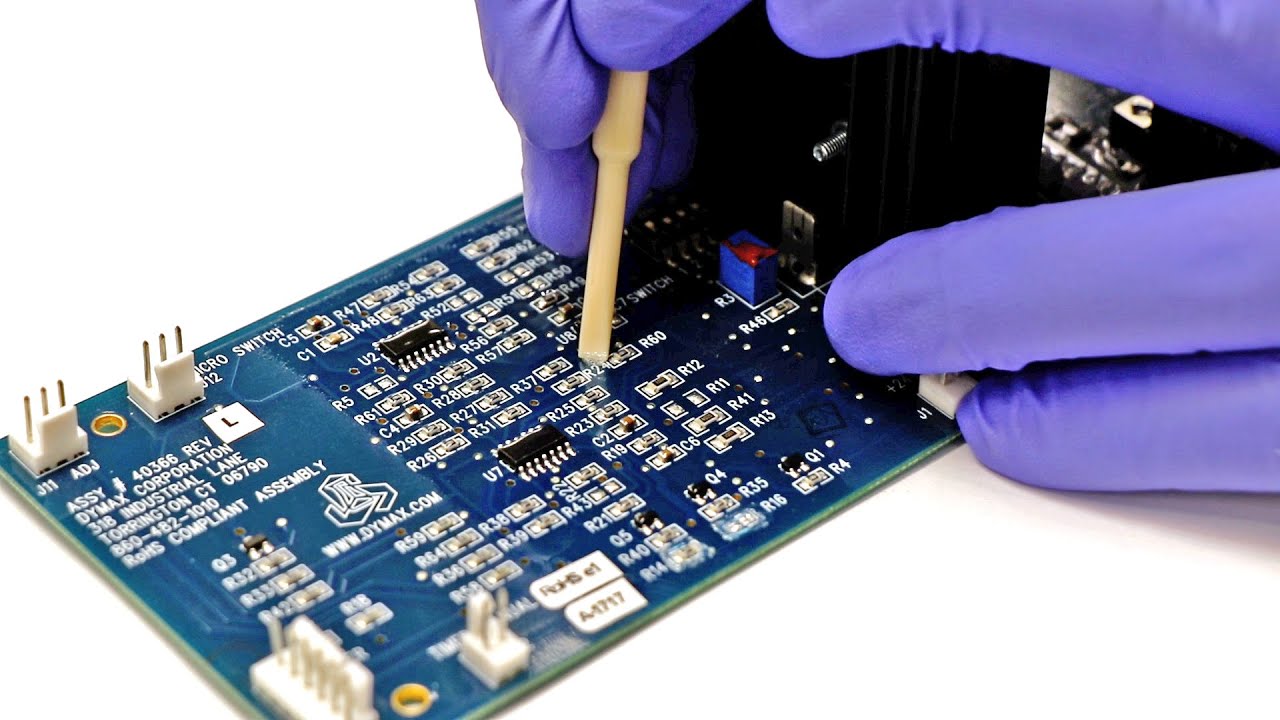

Removing conformal coating from SMT pads requires precision to ensure the pads remain intact for soldering or component replacement. Below are the most common techniques used in the industry for this delicate operation:

1. Chemical Solvent Method

This method uses solvents to dissolve the conformal coating. It’s effective for acrylic and some urethane coatings but requires caution to avoid damaging components.

- Process: Apply a small amount of solvent using a brush or cotton swab directly to the coated area. Allow it to sit for 1-2 minutes, then gently wipe away the softened coating with a lint-free cloth.

- Tools Needed: Solvent (specific to coating type), brushes, swabs, and protective gloves.

- Precautions: Use in a well-ventilated area to avoid inhaling fumes. Ensure the solvent is compatible with the PCB materials to prevent etching or residue buildup.

2. Mechanical Removal

Mechanical methods involve physically scraping or brushing off the coating. This is often used for thicker coatings like silicone or urethane.

- Process: Use a small blade, scalpel, or brush to carefully scrape the coating from SMT pads. Work slowly to avoid damaging the pads or nearby components.

- Tools Needed: Precision scalpels, soft brushes, and magnifying tools for visibility.

- Precautions: Avoid excessive force, as it can lift or scratch SMT pads, rendering them unusable.

3. Thermal Removal

Heat can soften some coatings, making them easier to remove. However, this method is risky due to the thermal sensitivity of SMT components.

- Process: Use a hot air rework station set to a low temperature (around 150-200°C) to soften the coating. Once softened, gently peel or scrape it away.

- Tools Needed: Hot air rework station with adjustable temperature control.

- Precautions: Monitor the temperature closely to prevent overheating components or desoldering nearby parts.

Conformal Coating Removal Around BGA Chips: Special Considerations

Ball Grid Array (BGA) chips are particularly challenging due to their dense array of solder balls and sensitivity to heat and mechanical stress. Conformal coating removal around BGA chips demands extra care to avoid damaging the chip or its connections. Here are key considerations and techniques:

- Localized Removal: Focus on removing coating only in the immediate area around the BGA chip. Use masking tape or protective barriers to shield adjacent components from solvents or heat.

- Micro-Abrasion: For tough coatings like parylene, micro-abrasion with fine abrasive powder can target small areas without affecting the BGA chip. Use a precision tool with a controlled nozzle to direct the abrasion.

- Low-Temperature Heat: If thermal removal is necessary, keep the temperature below 180°C to prevent reflow of the solder balls beneath the BGA chip. Use a focused hot air nozzle to avoid heating the entire board.

The goal is to expose just enough of the area for rework without compromising the integrity of the BGA chip or surrounding components. After removal, inspect the area under magnification to ensure no coating residue remains on the solder balls or pads.

Protecting SMT Components During Rework

Protecting SMT components during conformal coating removal and rework is critical to maintaining the functionality of the PCB. Here are some best practices to minimize risks:

- Use Protective Masking: Apply heat-resistant tape or silicone masks to cover sensitive components near the rework area. This prevents accidental exposure to solvents, heat, or mechanical stress.

- Control Heat Exposure: When using hot air tools, set the temperature and airflow to the minimum required for coating removal. Avoid prolonged heat exposure, as it can cause thermal stress to components like capacitors or ICs.

- Prevent ESD Damage: Use an ESD wrist strap and work on an anti-static mat to prevent static discharge. SMT components are highly susceptible to ESD, which can cause latent failures.

- Clean Thoroughly: After removal, clean the area with isopropyl alcohol (at least 99% purity) and a soft brush to remove any solvent residues or debris. Residues can interfere with soldering or lead to corrosion over time.

By taking these precautions, you can ensure that the surrounding SMT components remain undamaged during the rework process.

Precision Conformal Coating Removal Tools

Using the right tools is essential for safe and effective conformal coating removal. Here are some must-have precision tools for working with SMT components and BGA chips:

- Precision Scalpels and Blades: Ideal for mechanical removal, these tools allow for fine control when scraping coating from SMT pads.

- Micro-Brushes and Swabs: Perfect for applying solvents or cleaning small areas without spreading chemicals to adjacent components.

- Hot Air Rework Stations: Adjustable stations with fine nozzles are crucial for thermal removal, especially around heat-sensitive areas like BGA chips.

- Magnifying Equipment: A magnifying glass or stereo microscope helps in inspecting small SMT pads and ensures no residue or damage is overlooked.

- Micro-Abrasion Systems: For tough coatings, these systems use fine abrasive particles to remove material in a controlled manner without damaging the PCB.

Investing in high-quality tools can make a significant difference in the outcome of your rework process, reducing the risk of damage and improving efficiency.

SMT Rework Techniques After Coating Removal

Once the conformal coating is removed, the next step is often reworking or replacing SMT components. Here are some SMT rework techniques to ensure a successful repair:

- Desoldering Components: Use a hot air rework station or soldering iron with a fine tip to desolder components. For BGA chips, use a BGA rework station with precise temperature profiles to reflow solder balls evenly.

- Cleaning Pads: After desoldering, clean the SMT pads with isopropyl alcohol and a brush to remove old solder or flux residues. Use a solder wick for stubborn solder remnants.

- Reapplying Solder: Apply fresh solder paste or use pre-tinned components to ensure a strong connection during reassembly. For BGA chips, align the chip carefully using a stencil or alignment tool before reflow.

- Reapplying Conformal Coating: After rework, reapply a thin layer of conformal coating to the repaired area using a brush or spray for continued protection. Ensure the coating thickness is uniform (typically 25-75 micrometers) to avoid performance issues.

Following these steps ensures that the reworked area maintains the same level of reliability as the rest of the PCB.

Best Practices for Safe and Effective Removal

To wrap up, here are some overarching best practices for conformal coating removal and SMT rework:

- Always identify the coating type before starting the removal process to choose the most compatible method.

- Work in small, controlled areas to minimize the risk to surrounding components.

- Use magnification to inspect the PCB after removal for any leftover coating or damage to pads and components.

- Document the process, especially for complex boards, to replicate successful techniques in future rework tasks.

- Prioritize safety by wearing protective gear like gloves and goggles when working with solvents or abrasive tools.

Conclusion

Conformal coating removal for SMT components is a delicate operation that requires careful planning, the right tools, and precise techniques. Whether you're removing conformal coating from SMT pads or working around sensitive BGA chips, following the methods and precautions outlined in this guide can help you achieve a successful outcome. By protecting SMT components during rework and using precision conformal coating removal tools, you can maintain the integrity of your PCB while addressing necessary repairs. With the right SMT rework techniques, your boards will be back to optimal performance in no time.

At ALLPCB, we understand the complexities of PCB assembly and rework. Our expertise and resources are here to support you in tackling even the most delicate operations with confidence. Stay tuned for more insights and tips on PCB manufacturing and repair processes.

ALLPCB

ALLPCB