In the fast-paced world of electronics, maintaining signal integrity is critical, especially in high-speed PCB design. If you're wondering how to improve signal integrity with sequential build-up PCBs, the answer lies in leveraging their unique layered construction to minimize signal distortion, reduce crosstalk, and control impedance. Sequential build-up (SBU) PCBs, also known as build-up multilayer boards, allow for precise layer stacking and microvia technology, which can significantly enhance performance in high-speed applications. In this comprehensive guide, we'll dive deep into the techniques, benefits, and best practices for using SBU PCBs to ensure optimal signal integrity, helping you design reliable and efficient circuits for modern electronics.

What Is Signal Integrity and Why Does It Matter in PCB Design?

Signal integrity refers to the quality and reliability of electrical signals as they travel through a printed circuit board (PCB). In high-speed PCB design, where data rates often exceed 100 MHz or even reach into the gigahertz (GHz) range, maintaining signal integrity becomes a challenge. Poor signal integrity can lead to data corruption, communication errors, and system failures, impacting everything from consumer electronics to aerospace systems.

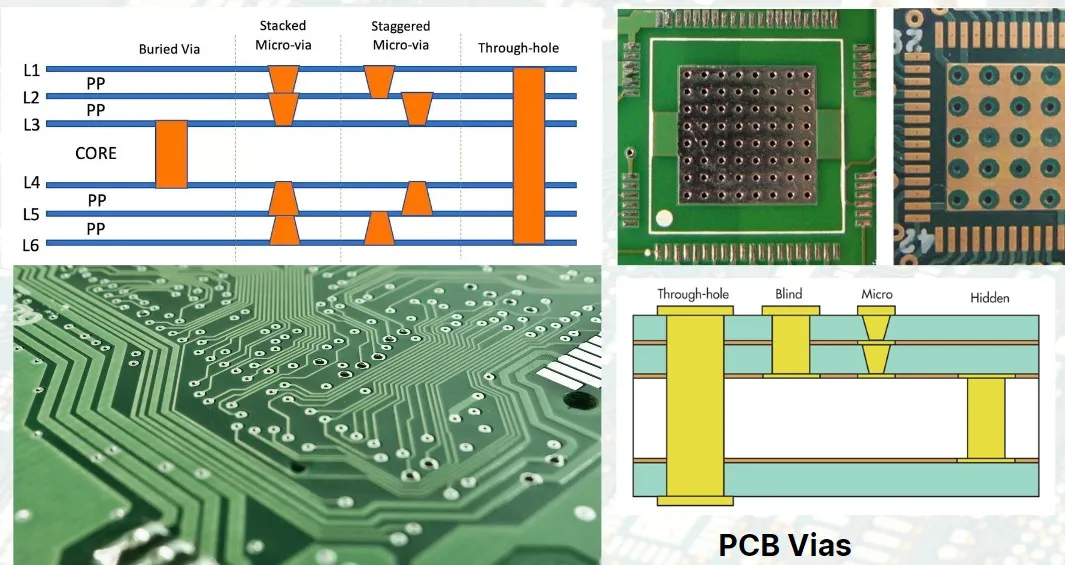

Common issues affecting signal integrity include crosstalk (unwanted interference between signals), electromagnetic interference (EMI), signal reflections, and impedance mismatches. These problems are amplified in high-speed designs due to shorter signal rise and fall times. Sequential build-up PCBs offer a solution by providing greater control over layer arrangement, via structures, and dielectric materials, which are essential for managing these challenges.

Understanding Sequential Build-Up PCBs

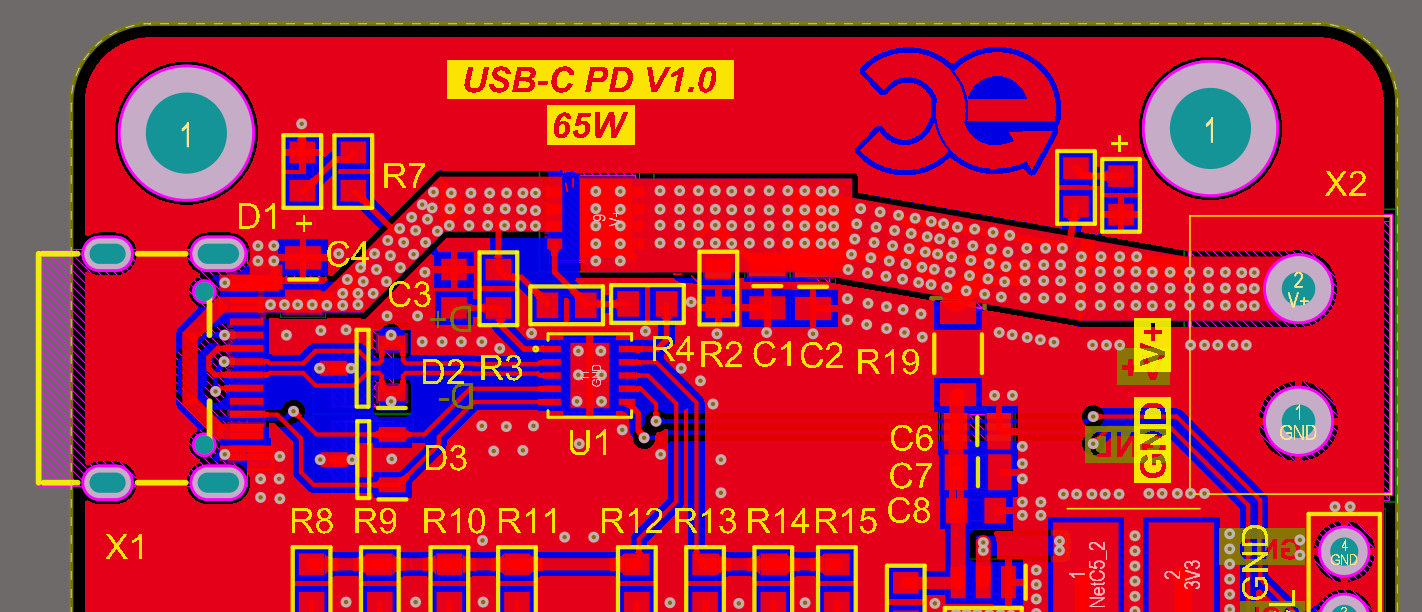

Sequential build-up PCBs are a type of multilayer board constructed through a step-by-step layering process. Unlike traditional multilayer PCBs, where all layers are laminated in a single step, SBU PCBs are built by adding layers sequentially, often using microvias to connect them. This method allows for higher layer counts, finer traces, and more precise control over the board's structure.

The key advantage of SBU technology is its ability to support high-density interconnects (HDI), which are crucial for modern electronics with compact designs and high-speed requirements. By using microvias (tiny vias with diameters as small as 0.1 mm), SBU PCBs reduce signal path lengths and minimize parasitic effects, directly improving signal integrity.

Key Benefits of Sequential Build-Up PCBs for Signal Integrity

Sequential build-up PCBs provide several advantages that make them ideal for high-speed applications. Let's explore how these benefits translate into better signal integrity:

- Reduced Signal Path Lengths: Microvias in SBU PCBs create shorter connections between layers, reducing signal delays and minimizing the risk of reflections. For instance, a traditional through-hole via might span multiple layers, creating a signal path of 2-3 mm, while a microvia can reduce this to under 0.5 mm.

- Improved Impedance Control: SBU technology allows for precise layer stacking and dielectric material selection, ensuring consistent impedance across signal paths. Maintaining a target impedance, such as 50 ohms for many high-speed signals, is critical to avoiding reflections.

- Lower Crosstalk: The ability to place ground planes closer to signal layers in SBU PCBs helps shield signals from interference. This reduces crosstalk, which can degrade signal quality in densely packed designs.

- Enhanced Thermal Management: High-speed circuits often generate significant heat, which can affect signal performance. SBU PCBs can incorporate thermal vias and optimized layer structures to dissipate heat more effectively.

Signal Integrity Techniques Using Sequential Build-Up PCBs

Designing for signal integrity with SBU PCBs requires a combination of careful planning and proven techniques. Below are actionable strategies to optimize your high-speed PCB design:

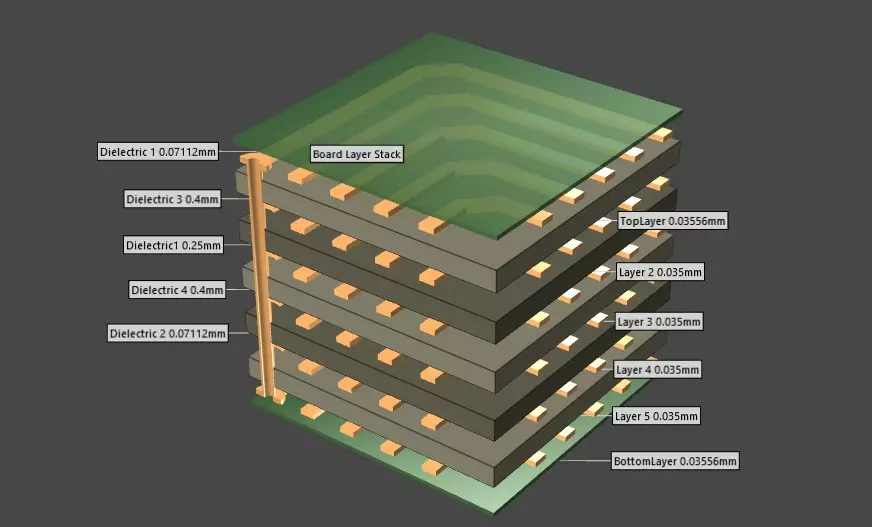

1. Optimize Layer Stacking for Signal Isolation

In SBU PCBs, you have greater flexibility to design the layer stack-up. Place high-speed signal layers between ground planes to create a controlled impedance environment and shield against crosstalk. For example, a 10-layer SBU PCB might have signal layers at layers 2 and 8, with adjacent ground planes at layers 1, 3, 7, and 9. This configuration minimizes interference and ensures stable signal transmission at frequencies above 1 GHz.

2. Use Microvias to Minimize Signal Distortion

Microvias, a hallmark of SBU technology, are smaller and more precise than traditional vias. They reduce inductance and capacitance, which can distort high-speed signals. When designing, use stacked or staggered microvias to connect adjacent layers, keeping signal paths as short as possible. For instance, a microvia with a diameter of 0.1 mm and a length of 0.2 mm introduces far less parasitic inductance compared to a through-hole via spanning 1.6 mm across a board.

3. Control Impedance with Dielectric Materials

Impedance mismatches are a leading cause of signal reflections in high-speed designs. SBU PCBs allow you to select specific dielectric materials with known properties, such as a dielectric constant (Dk) between 3.5 and 4.2 for common high-speed applications. Work with your PCB manufacturer to choose materials and layer thicknesses that maintain a consistent impedance, such as 50 ohms for single-ended signals or 100 ohms for differential pairs.

4. Minimize Crosstalk with Proper Trace Spacing

In high-density designs, traces carrying high-speed signals can interfere with each other if placed too closely. With SBU PCBs, you can achieve finer trace widths (down to 0.075 mm) and tighter spacing. However, ensure a spacing of at least 3 times the trace width between adjacent high-speed traces to reduce crosstalk. For example, a 0.1 mm wide trace should have at least 0.3 mm separation from its neighbor.

5. Implement Ground Planes and Power Integrity

A solid ground plane is essential for providing a low-impedance return path for signals, reducing noise and EMI. In SBU PCBs, you can dedicate entire layers to ground and power, ensuring minimal interruptions. Avoid splitting ground planes under high-speed signal traces, as this can disrupt the return path and cause signal degradation.

Challenges in High-Speed PCB Design and How SBU PCBs Help

High-speed PCB design comes with inherent challenges that can compromise signal integrity. Here’s how sequential build-up PCBs address these issues:

- Signal Reflections: Reflections occur when there’s an impedance mismatch along the signal path. SBU PCBs allow for tighter control over trace geometry and via structures, reducing mismatches. Simulations can predict reflections at frequencies like 2.5 GHz, helping you adjust designs before fabrication.

- Electromagnetic Interference (EMI): EMI can disrupt signals and affect nearby components. The layered structure of SBU PCBs, with dedicated ground planes, acts as a shield, minimizing EMI in designs operating at 10 GHz or higher.

- Thermal Issues: High-speed circuits generate heat, which can alter material properties and signal behavior. SBU PCBs can integrate thermal vias and heat-spreading layers to manage temperatures, ensuring consistent performance.

Best Practices for Designing SBU PCBs for Signal Integrity

To maximize the benefits of sequential build-up PCBs in high-speed applications, follow these best practices:

- Collaborate Early with Your Manufacturer: Discuss your signal integrity requirements, such as target impedance and frequency range, during the design phase. This ensures the right materials and processes are used during fabrication.

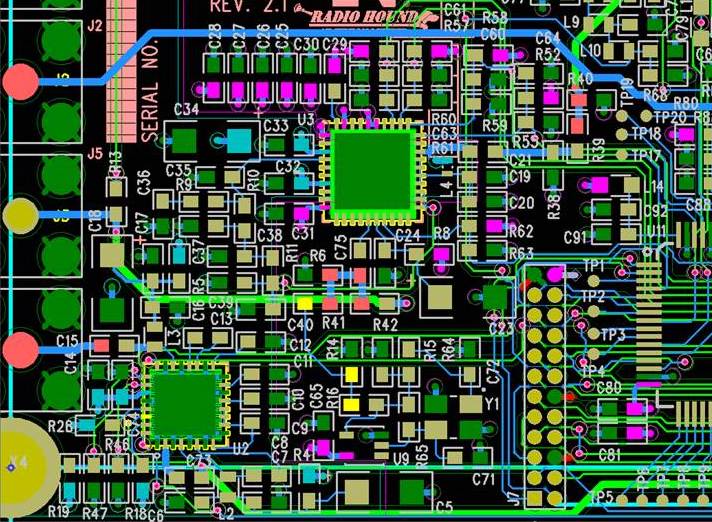

- Use Simulation Tools: Before finalizing your design, use simulation software to model signal behavior, impedance, and crosstalk. Tools can help identify potential issues at frequencies like 5 GHz, allowing for adjustments in layer stack-up or via placement.

- Test Prototypes: After fabrication, test your PCB prototypes under real-world conditions to verify signal integrity. Measure parameters like eye diagrams and bit error rates to ensure performance meets expectations.

- Document Design Rules: Maintain a set of design rules for trace widths, via sizes, and layer configurations specific to SBU PCBs. For example, specify a minimum microvia diameter of 0.1 mm and a trace-to-trace spacing of 0.3 mm for high-speed signals.

Real-World Applications of SBU PCBs in High-Speed Design

Sequential build-up PCBs are widely used in industries where signal integrity is paramount. In telecommunications, they support high-speed data transfer in 5G infrastructure, handling frequencies up to 28 GHz. In computing, SBU PCBs are integral to server motherboards and memory modules like DDR4, where data rates exceed 3.2 Gbps. Even in aerospace and defense, these boards ensure reliable communication in radar and avionics systems, where signal distortion can have critical consequences.

Conclusion: Elevate Your High-Speed Designs with SBU PCBs

Improving signal integrity with sequential build-up PCBs is a game-changer for high-speed PCB design. By leveraging the precision of SBU technology, including microvias, optimized layer stacking, and controlled impedance, you can minimize signal distortion, reduce crosstalk, and ensure reliable performance in even the most demanding applications. Whether you're designing for telecommunications, computing, or aerospace, adopting signal integrity techniques with SBU PCBs will help you stay ahead in the fast-evolving world of electronics.

Start by incorporating the strategies and best practices outlined in this guide into your next project. With careful planning and collaboration with your PCB manufacturer, you can achieve exceptional signal integrity and build circuits that meet the rigorous demands of modern technology.

ALLPCB

ALLPCB