Advancements in clinical medicine have shifted healthcare from traditional empirical models to evidence-based approaches, improving patient outcomes. However, disparities in access to advanced medical technologies persist, particularly between urban and rural areas, as well as across racial, ethnic, and gender groups. The COVID-19 pandemic highlighted the link between high-quality medical interventions and health outcomes, underscoring the impact of limited access to advanced technologies on vulnerable populations.

Wearable Sensors: A New Paradigm

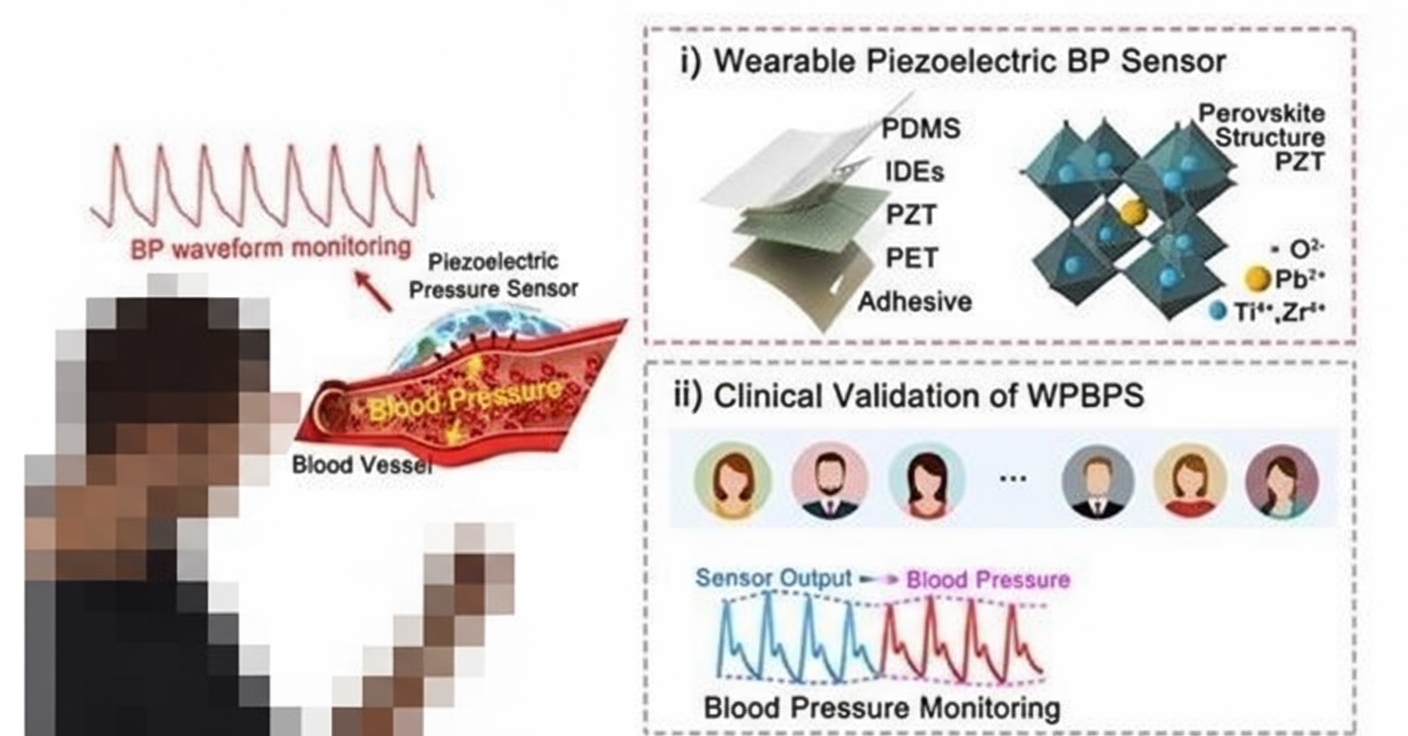

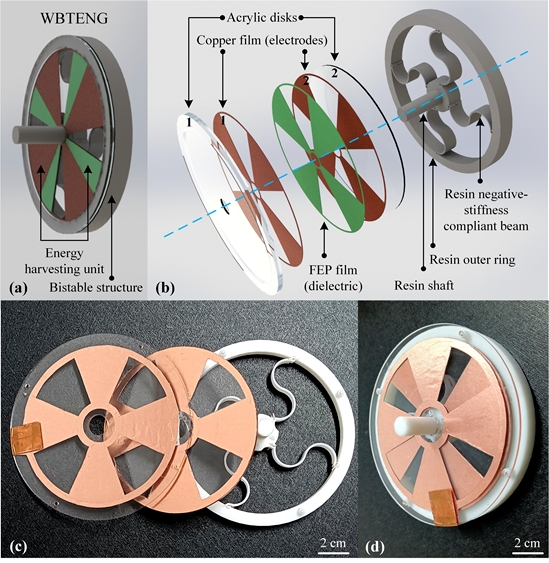

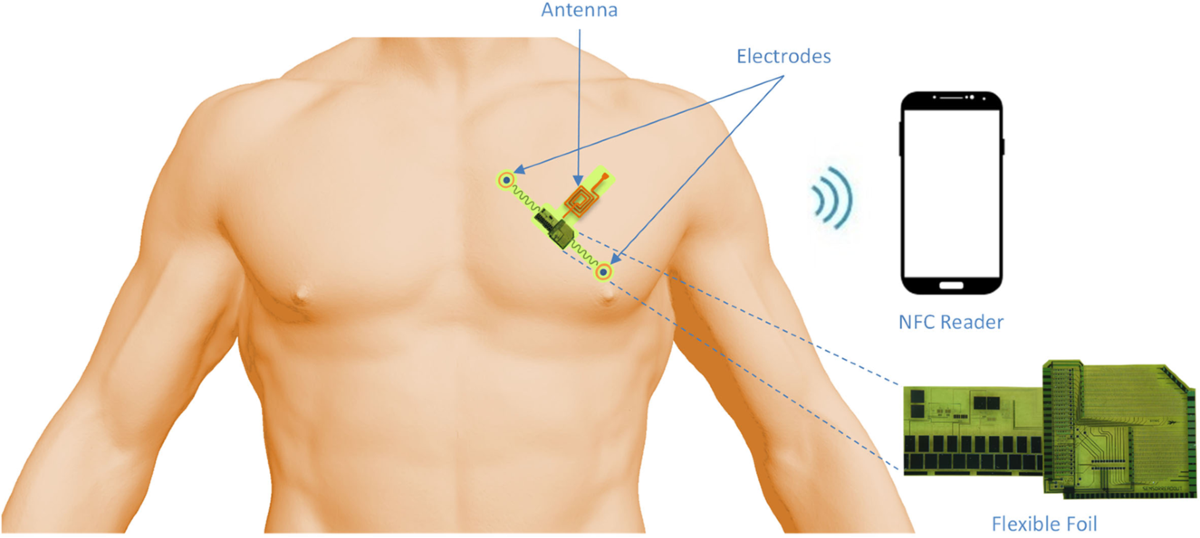

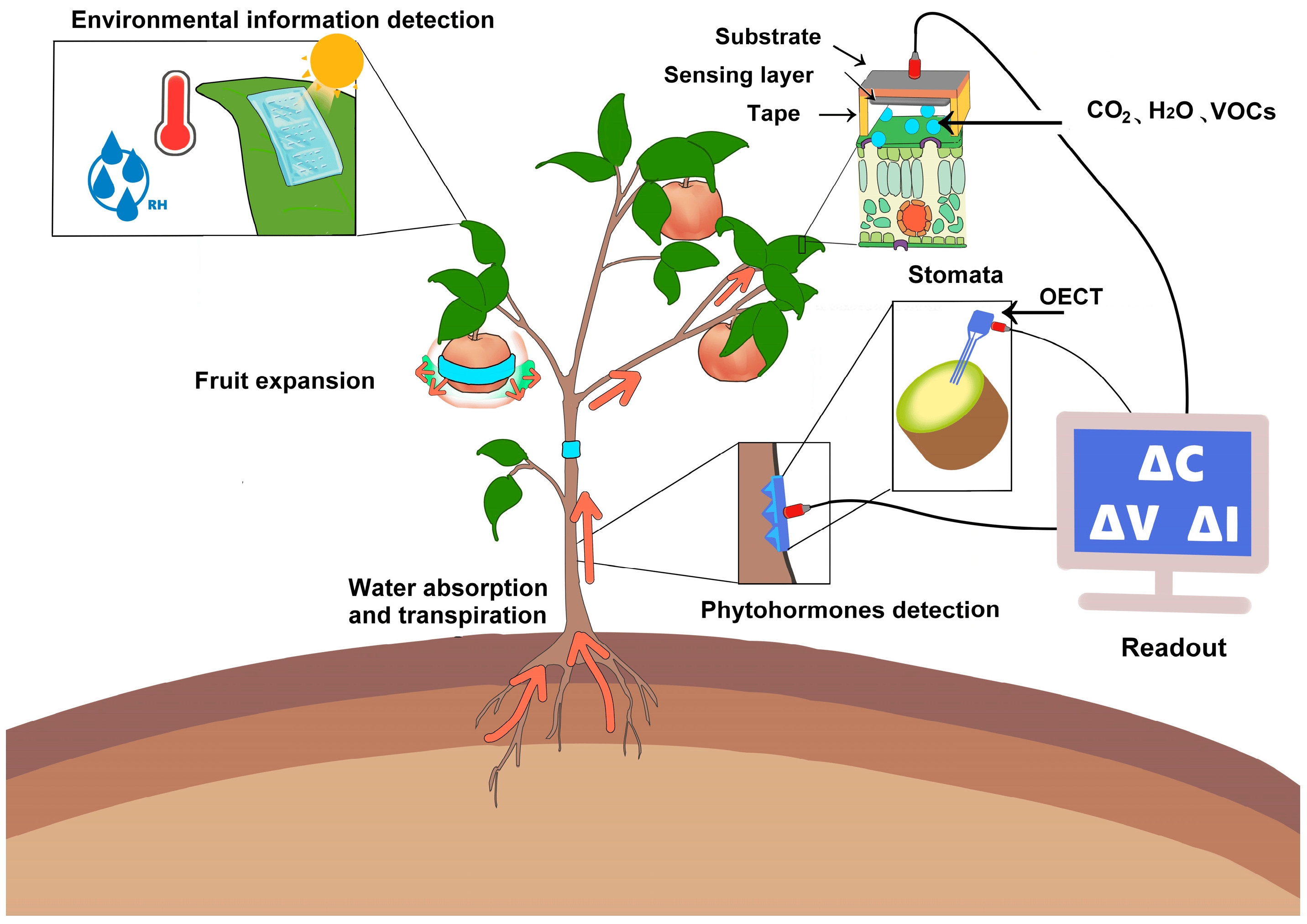

Emerging wearable sensors represent a transformative approach to physiological monitoring, addressing healthcare challenges through innovations in materials science, chemistry, engineering, and flexible electronics. These devices conform to the body¡¯s contours, capturing physiological and biochemical signals critical for health assessments.

Traditional clinical monitoring relies on expensive, stationary equipment for intermittent data collection, limiting comprehensive health tracking. In contrast, wearable systems integrate multi-parameter measurements, smartphone connectivity, and low-power wireless communication, enabling clinical-grade monitoring in diverse settings.

Widespread adoption of these sensors could bridge geographic, economic, and resource gaps, reducing disparities in advanced healthcare access and supporting proactive interventions using real-time data. However, high-cost manufacturing and specialized training requirements hinder their use in resource-constrained regions. Prototyping these platforms demands complex, time-intensive, and costly processes, cleanroom facilities, and skilled technicians.

Challenges in Wearable Sensor Manufacturing

Methods like screen printing for flexible electronics offer low-cost potential but face limitations in resolution, material options, and performance compared to established manufacturing techniques. These challenges highlight the need for advanced, accessible manufacturing methods suited for miniaturized wearable sensor prototypes.

Additive Manufacturing: A Solution

Additive manufacturing (AM), or 3D printing, enables precise, customized geometries and functionalities, offering unmatched opportunities for prototyping physical objects. Using computer-aided design (CAD) software, AM builds objects layer-by-layer from digital models, eliminating the need for specialized facilities or highly trained personnel.

AM streamlines prototyping, accelerates development, and reduces barriers to producing wearable sensor platforms. By enabling rapid fabrication from diverse materials, it fosters innovation and broadens access to advanced healthcare technologies, particularly in underserved regions.

Research Insights

A review article from the University of Hawaii¡¯s Department of Mechanical Engineering, published in Advanced Sensor Research, explores AM¡¯s role in wearable sensor development. Titled ¡°Emerging Additive Manufacturing Methods for Wearable Sensors: Opportunities to Expand Access to Personalized Health Monitoring,¡± it highlights AM¡¯s potential to democratize advanced diagnostics.

The review details AM processes for wearable platforms, their advantages, challenges, and representative examples categorized by physiological and biochemical signals. It emphasizes AM¡¯s ability to simplify manufacturing, enhance scalability, and address healthcare disparities.

Future Directions

Realizing AM¡¯s potential for fully integrated, customized wearable systems requires collaboration across academia, industry, and medicine. Innovations in printable inks, material biocompatibility, and process scalability are critical. Enhancing AM resolution and speed while maintaining quality is also essential.

Integrating artificial intelligence (AI) and machine learning can optimize device design, manufacturing parameters, and real-time biosignal analysis, accelerating platform development. Seamless integration of heterogeneous components into unified platforms is vital for personalized health monitoring ecosystems.

Through collaborative innovation, AM can transform the development and production of next-generation wearable sensors, enhancing global access to advanced healthcare technologies.

ALLPCB

ALLPCB