In the fast-paced world of electronics manufacturing, efficiency is everything. Surface Mount Technology (SMT) has become the backbone of modern PCB assembly, offering speed, precision, and cost savings. If you're looking to achieve efficient PCB assembly with SMT, improve your SMT process, ensure SMT quality control, or learn how to improve manufacturing, you're in the right place. This guide from ALLPCB dives deep into actionable strategies and best practices to help you maximize efficiency at every step of the SMT process.

What is Surface Mount Technology (SMT) and Why Does It Matter?

SMT is a method of assembling electronic circuits where components are mounted directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole technology, SMT eliminates the need for drilling holes and manually inserting leads, allowing for faster, automated assembly and higher component density. This technology is critical for producing compact, reliable, and high-performance devices used in industries like consumer electronics, automotive, medical, and aerospace.

The benefits of SMT are clear: it reduces labor and material costs, supports smaller designs, and enables high-speed production. For instance, some advanced placement machines can handle over 136,000 components per hour, showcasing the incredible efficiency of this technology. However, to fully harness these advantages, manufacturers must focus on optimizing their processes and maintaining strict quality control.

Key Strategies for Efficient PCB Assembly with SMT

Achieving efficient PCB assembly with SMT starts with streamlining every aspect of the production process. Below are proven strategies to help you save time, reduce costs, and boost output without compromising quality.

1. Optimize PCB Design for SMT Assembly

The foundation of efficient SMT assembly lies in the PCB design itself. A well-thought-out design minimizes errors during manufacturing and ensures smooth component placement. Focus on these design tips:

- Standardize Component Sizes: Use standard component packages (like 0402 or 0603 for resistors and capacitors) to simplify machine programming and reduce setup time.

- Proper Pad Spacing: Ensure adequate spacing between pads to prevent solder bridging. For high-density designs, a minimum pad-to-pad spacing of 0.2 mm is often recommended.

- Component Orientation: Align components in the same direction whenever possible to speed up pick-and-place operations and ensure even heat distribution during reflow soldering.

By prioritizing Design for Manufacturability (DFM), you can avoid costly rework and delays, making your SMT process more efficient from the start.

2. Invest in High-Speed Equipment

The right equipment can make a significant difference in SMT efficiency. Modern pick-and-place machines, for example, can achieve placement accuracy within 0.01 mm, drastically reducing errors. Additionally, advanced reflow ovens with precise temperature control (within ±1°C) ensure consistent soldering results, even for complex boards with varying thermal masses.

While high-end equipment may require a larger upfront investment, the long-term gains in speed and reliability often outweigh the costs. For smaller operations, modular systems that can scale with production needs are a practical choice.

3. Streamline Material Handling

Efficient material handling is often overlooked but plays a vital role in SMT assembly. Delays in sourcing components or managing inventory can bottleneck production. Implement these practices:

- Use automated feeders to supply components to pick-and-place machines without interruption.

- Organize inventory with clear labeling and barcode systems to minimize retrieval time.

- Partner with reliable suppliers to ensure timely delivery of high-quality components.

By reducing downtime caused by material shortages or mismanagement, you can keep your SMT line running at full capacity.

Improving the SMT Process: Tips for Speed and Precision

Improving the SMT process involves fine-tuning each stage of assembly, from solder paste application to final inspection. Here are actionable ways to enhance performance and achieve consistent results.

1. Perfect Solder Paste Application

Solder paste application is a critical step in SMT assembly. Poor application can lead to defects like insufficient solder or bridging. To improve this process:

- Use high-quality stencils with precise apertures. Laser-cut stencils, for instance, offer better accuracy for fine-pitch components (down to 0.4 mm pitch) compared to traditional etched stencils.

- Regularly clean stencils to prevent paste buildup, which can cause uneven deposits.

- Monitor paste viscosity and storage conditions to maintain consistency. Ideal storage temperature for solder paste is typically between 2°C and 10°C.

Consistency in solder paste application ensures strong, reliable joints and reduces the risk of defects during reflow.

2. Fine-Tune Reflow Soldering Profiles

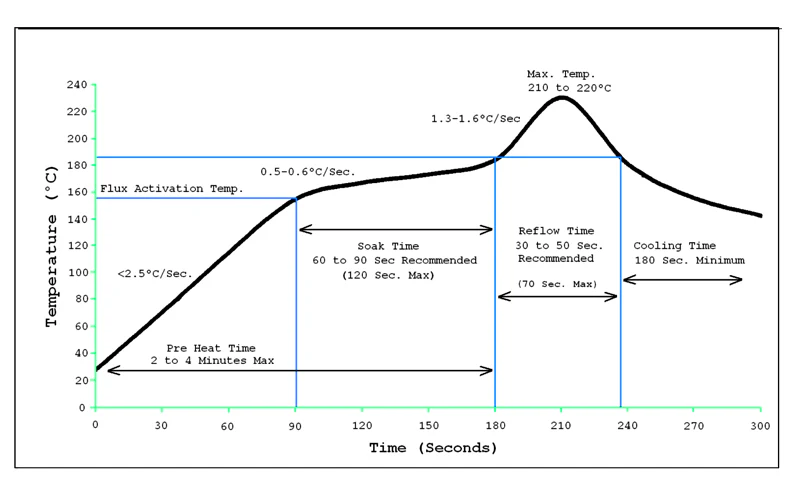

Reflow soldering is where components are permanently bonded to the PCB. An optimized reflow profile prevents issues like tombstoning or cold solder joints. Key considerations include:

- Preheat the board gradually to avoid thermal shock. A typical preheat slope is 1-3°C per second up to 150°C.

- Ensure peak temperature (usually 235-250°C for lead-free solder) is reached for the right duration, often 20-40 seconds, to achieve proper wetting.

- Cool the board at a controlled rate (2-4°C per second) to minimize stress on components.

Regularly test and adjust your reflow oven settings based on board size, component types, and solder paste specifications to maintain precision.

3. Train Operators for Peak Performance

Even with advanced automation, skilled operators are essential for improving the SMT process. Well-trained staff can troubleshoot issues, maintain equipment, and ensure smooth operations. Provide regular training on machine programming, quality standards, and safety protocols to keep your team at the top of their game.

SMT Quality Control: Ensuring Flawless Results

SMT quality control is non-negotiable for delivering reliable products. Defects in SMT assembly can lead to costly rework or product failures, damaging your reputation. Here’s how to maintain high standards at every stage.

1. Implement Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) systems are a cornerstone of SMT quality control. These systems use high-resolution cameras to detect defects like misaligned components, missing parts, or solder issues with over 99% accuracy. By integrating AOI after placement and reflow, you can catch errors early and prevent defective boards from reaching the next stage.

2. Conduct Regular Process Audits

Periodic audits of your SMT line help identify inefficiencies and quality risks. Check for equipment calibration, operator adherence to protocols, and material quality. For example, verify that pick-and-place machines maintain placement accuracy within 0.02 mm to avoid cumulative errors in high-density designs.

3. Use Traceability Systems

Traceability is a powerful tool for SMT quality control. By tracking components, processes, and batches through barcode scanners or Manufacturing Execution Systems (MES), you can pinpoint the source of defects and take corrective action. This approach also ensures compliance with industry standards, especially in regulated sectors like medical and aerospace.

How to Improve Manufacturing with SMT: Broader Impacts

Beyond individual process improvements, SMT offers opportunities to transform your entire manufacturing operation. Here’s how to leverage this technology for long-term success.

1. Scale Production with Automation

SMT’s compatibility with automation allows manufacturers to scale production without proportional increases in labor costs. Automated lines can handle thousands of boards per day, meeting growing demand while maintaining consistency. For instance, a fully automated SMT line can reduce cycle time per board by up to 50% compared to semi-manual setups.

2. Reduce Waste and Costs

SMT minimizes material waste by using smaller components and eliminating the need for drilled holes. Additionally, optimizing your process through DFM and quality control reduces scrap rates. A well-run SMT operation can achieve defect rates below 100 parts per million (PPM), translating to significant cost savings.

3. Stay Competitive with Innovation

The electronics industry evolves rapidly, and SMT keeps you ahead of the curve. By adopting the latest advancements, such as micro-SMT for ultra-small components (down to 01005 size), you can cater to cutting-edge applications like wearable devices and IoT products. Staying innovative ensures your manufacturing remains relevant and competitive.

Overcoming Common SMT Challenges

While SMT offers numerous benefits, it comes with challenges that can impact efficiency and quality. Here’s how to address some common issues:

- Component Miniaturization: As components shrink, placement and soldering become more complex. Use high-precision equipment and regularly update DFM guidelines to handle fine-pitch parts.

- Thermal Management: High-density boards can suffer from uneven heating. Design with thermal vias and use reflow ovens with multiple zones for better heat distribution.

- Supply Chain Delays: Component shortages can halt production. Maintain buffer stock for critical parts and build strong supplier relationships to mitigate risks.

Proactively tackling these challenges ensures your SMT process remains efficient and reliable, even as demands grow.

Conclusion: Building a Future with Efficient SMT

Maximizing efficiency with SMT is about more than just speed—it’s about precision, quality, and adaptability. By focusing on efficient PCB assembly with SMT, improving your SMT process, enforcing strict SMT quality control, and learning how to improve manufacturing, you can achieve outstanding results that benefit your business and your customers. From optimizing designs and investing in automation to prioritizing training and traceability, every step you take brings you closer to a streamlined, cost-effective operation.

At ALLPCB, we’re committed to supporting manufacturers with the tools and expertise needed to excel in SMT assembly. Whether you’re refining an existing process or starting from scratch, the strategies in this guide provide a roadmap to success. Implement these practices, stay ahead of industry trends, and watch your manufacturing efficiency soar.

ALLPCB

ALLPCB