With advances in electronics technology, electronic products are becoming smaller and more densely packed, increasing power and cooling demands for devices. Heat generated during device operation must be removed promptly to avoid degrading performance and shortening lifetime. Thermal interface materials (TIM), such as thermal grease and phase-change thermal materials, are widely used on IGBT power devices to fill gaps between mounting surfaces and the device heat-spreading surface, reducing the impact of high temperatures on the device.

1. IGBT thermal conduction mechanism

As shown in the IGBT thermal conduction diagram, heat generated by losses inside the chip is conducted through the chip to the package base. A small amount of heat is released directly to the environment from the package by convection and radiation, while the majority is conducted through the base, via an insulating pad, to the heatsink, and finally from the heatsink into the air.

The total thermal resistance from the chip to the ambient consists of three parts: junction-to-case thermal resistance Rj-c, case-to-sink contact thermal resistance Rc-s, and sink-to-ambient thermal resistance Rs-a. The total thermal resistance is given by:

Rj-a = Rj-c + Rc-s + Rs-a

Thus, Rj-c and Rs-a are determined by the IGBT itself and the overall cooling solution. The role of thermal interface materials is to reduce the contact thermal resistance Rc-s, thereby lowering the total thermal resistance of the system.

Most IGBT power module failures are related to thermal issues, so reliable thermal management is essential for long-term operation. Air gaps between the power device and the heatsink create large contact thermal resistance, significantly increasing the temperature difference across the interfaces. To ensure efficient, safe, and stable operation of IGBT modules, thermal management is a critical aspect of product design and application.

2. Role of thermal interface materials

In IGBT heat conduction, most heat is transferred through metal contact between the IGBT heat-spreading surface and the heatsink surface, commonly copper or aluminum. Surface irregularities leave air in the gaps, and air has a thermal conductivity of only 0.025 W/(m·K), which severely impedes heat transfer. Applying a thermal interface material to the IGBT heat-spreading surface before assembly allows the material, under clamping and screw pressure, to displace the trapped air and fill the gaps. Typical thermal conductivities for such materials range from 0.8 to 4 W/(m·K), which is 32 to 160 times that of air. While bulk metal-to-metal conduction still handles the main heat flow, TIMs substantially improve heat transfer across contact surfaces, reducing thermal resistance and increasing cooling efficiency.

As IGBT devices move toward higher power and greater integration, TIMs face stricter requirements such as low thermal resistance and long-term reliability. Choosing the right TIM requires considering thermal performance as well as manufacturability, maintenance, and long-term stability.

3. Characteristics of IGBT thermal interface materials

Thermal interface materials help power modules dissipate heat and extend service life. Common TIMs used for IGBT cooling are thermal grease and phase-change thermal materials. Low- to mid-range IGBT modules typically use standard or high-performance thermal grease, while high-end modules often use phase-change materials.

3.1 Thermal grease

Thermal grease, also called thermal paste, has good surface wetting and low contact thermal resistance and was one of the first TIMs used in IGBT modules. It is a paste-like thermal compound based on silicone, formulated with heat-resistant, highly thermally conductive fillers to form a silicone-based composite. It exhibits low oil separation, resistance to high and low temperatures, and resistance to water, ozone, and climate aging, maintaining a paste-like state from -50°C to +230°C. However, thermal grease performance can degrade after 1-2 years of use.

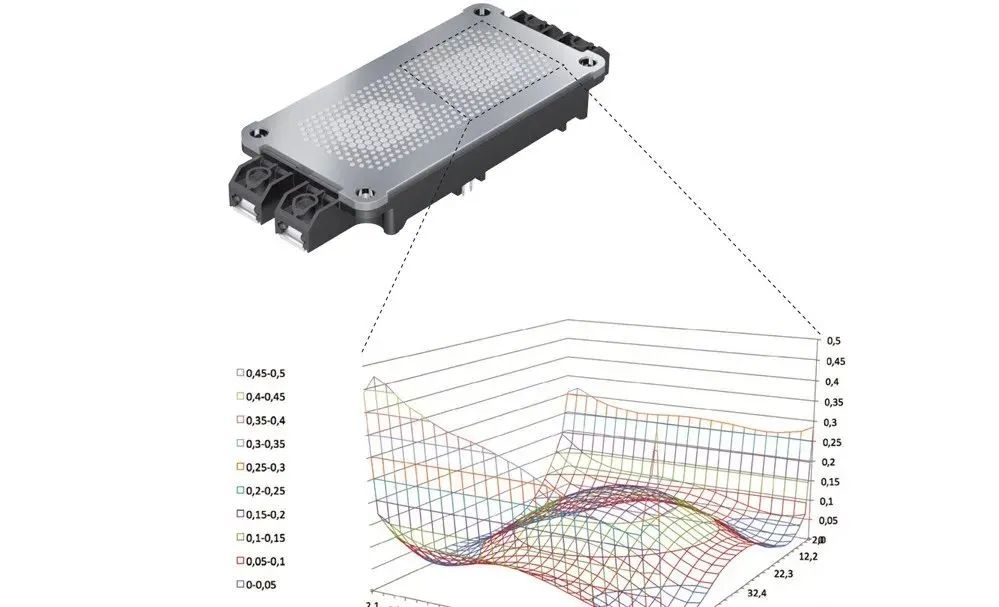

Coating process is critical to ensure uniform distribution of thermal grease on the IGBT, which directly affects actual thermal performance. Common coating methods for IGBT thermal grease include roller coating and screen printing. Compared with roller coating, screen printing provides better control of grease thickness uniformity on the IGBT, improving cooling effectiveness and service life.

3.2 Phase-change thermal materials

Phase-change thermal materials, also called phase-change thermal pastes, are insulating materials formulated from high-performance organic polymers with high-thermal-conductivity fillers and phase-change additives. They are suitable for thermal transfer between heatsinks and high-heat-generating power components.

The key feature of phase-change materials is their phase-change behavior. At room temperature they are solid and easy to handle, allowing them to be used as clean, rigid preforms on heatsink or device surfaces. When the device reaches operating temperature, the material softens and, under clamping pressure, behaves like thermal grease to conform to both mating surfaces and fill gaps. This ability to fully fill interface voids and gaps allows phase-change materials to be pre-applied for easier transport and assembly while delivering performance similar to thermal grease.

Another major advantage of phase-change materials is their stability and durability. They can maintain excellent thermal stability after extended thermal cycling and HAST testing, and their thermal resistance tends to decrease over time. Compared with thermal grease, phase-change materials generally offer better durability and thermal performance, though at higher cost, which can improve the long-term reliability of assemblies using IGBT and similar electronic devices.

ALLPCB

ALLPCB