Introduction

As global attention to energy efficiency increases and demand for renewable energy rises, traditional silicon-based power devices are reaching performance limits. Against this backdrop, silicon carbide (SiC) power devices, with superior physical properties and energy efficiency, are considered a key technology for next-generation energy systems. This article examines SiC power device operation, advantages, application scenarios, challenges, and future trends.

Operation

SiC power devices are fabricated from silicon carbide semiconductor material. SiC is a wide-bandgap semiconductor with higher electron saturated drift velocity and thermal conductivity than silicon, along with a higher critical breakdown electric field. These properties enable SiC devices to operate at higher voltages, currents, and temperatures while offering improved efficiency and thermal stability.

Advantages

- High temperature stability: SiC power devices can operate stably in environments up to 600°C, whereas conventional silicon devices are typically limited to 150°C–200°C.

- High efficiency: The low conduction and switching losses of SiC material significantly improve device efficiency.

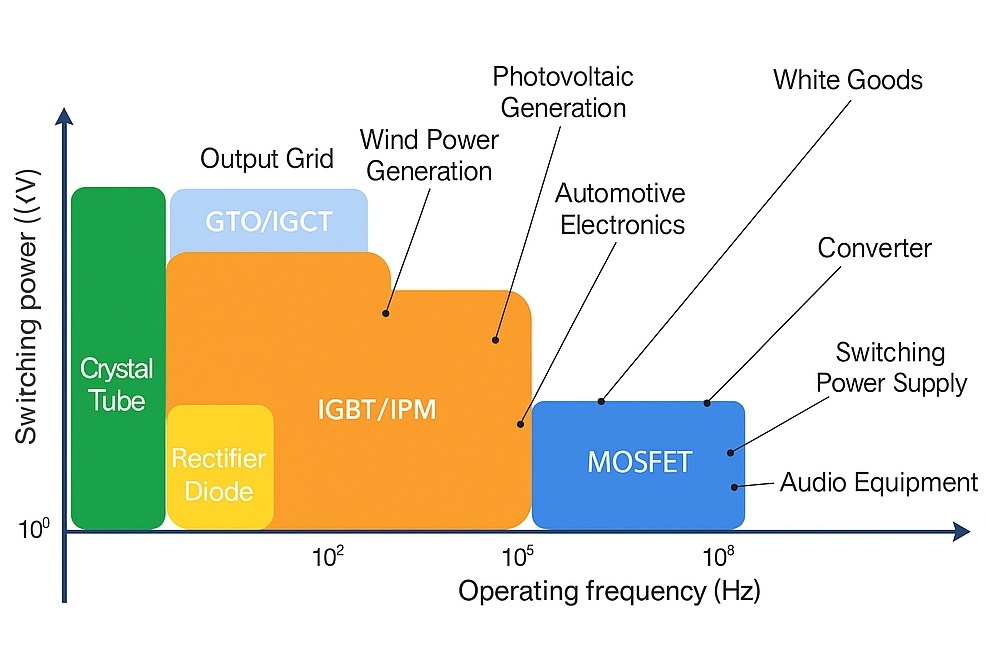

- High-frequency operation: SiC devices support higher switching frequencies, reducing the size and cost of energy storage components.

- Miniaturization: Higher efficiency and improved thermal performance reduce cooling requirements, allowing more compact system designs.

Applications

- Power transmission and distribution: SiC devices are applicable to high-voltage direct current (HVDC) transmission systems and smart grids, improving transmission efficiency and reducing losses.

- Automotive: In electric and hybrid vehicles, SiC power devices improve energy efficiency and reduce weight, extending battery range and shortening charging times.

- Renewable energy systems: SiC devices enhance conversion efficiency in solar inverters and wind power systems, supporting broader adoption of renewable energy.

- Industrial motor drives: SiC power devices can improve motor efficiency and dynamic response while reducing energy consumption.

Challenges

Despite clear advantages, SiC power devices face several challenges for wider adoption:

- Cost: SiC devices currently have higher production costs than conventional silicon devices, particularly in wafer fabrication and processing.

- Packaging and reliability: High-temperature and high-power applications place greater demands on packaging and long-term reliability of SiC devices.

- Market acceptance: Wider industrial and consumer adoption will require time and demonstration of long-term benefits and cost-effectiveness.

Future Trends

Cost reduction through manufacturing advances: As fabrication technologies improve and production scales up, SiC device costs are expected to decline.

Innovative packaging: New packaging solutions designed for high-temperature and high-power conditions will be a major research focus.

System integration: Integration of SiC devices with other electronic components will enable more efficient and compact power electronics systems.

Cross-industry adoption: As performance advantages become more evident, SiC power devices are likely to see broader use across automotive, energy, power, and industrial sectors.

Conclusion

Silicon carbide power devices offer significant performance benefits and are progressively contributing to advances in energy efficiency and power electronics. Although cost and technical challenges remain, ongoing research and technological progress are expected to enable wider deployment of SiC devices, supporting more efficient and sustainable energy solutions.

ALLPCB

ALLPCB