When it comes to designing and manufacturing printed circuit boards (PCBs), selecting the right surface finish is a critical decision that impacts both manufacturability and long-term reliability. A PCB surface finish protects the exposed copper on the board and ensures proper soldering performance during assembly. But with options like HASL, ENIG, ENEPIG, and immersion silver, how do you choose the best one for your project? In this comprehensive guide, we’ll break down the most popular PCB surface finishes, focusing on manufacturability considerations, soldering performance, and corrosion resistance to help you make an informed choice.

Whether you’re an engineer working on a high-reliability application or a designer optimizing for cost, understanding the strengths and limitations of each finish is essential. Let’s dive into the details of PCB surface finishes and explore how they can affect your project’s success.

What Is a PCB Surface Finish and Why Does It Matter?

A PCB surface finish is a thin coating applied to the exposed copper areas of a circuit board. Its primary roles are to prevent oxidation of the copper, which can degrade electrical performance, and to provide a solderable surface for attaching components during assembly. Without a proper finish, copper can corrode when exposed to air, leading to poor connections and potential board failure.

The choice of surface finish directly affects the board’s manufacturability—how easily it can be produced and assembled—as well as its reliability in terms of soldering performance and resistance to environmental factors like humidity and temperature. For instance, a finish that offers excellent corrosion resistance might be ideal for harsh environments, while another might be chosen for its low cost and ease of use in high-volume production.

In the sections below, we’ll explore the most common PCB surface finish options, comparing their key characteristics to help you decide which one suits your needs best.

Common PCB Surface Finish Options

There are several types of PCB surface finishes available, each with unique properties that make them suitable for specific applications. Below, we’ll discuss HASL, ENIG, ENEPIG, and immersion silver in detail, focusing on their manufacturability, soldering performance, and corrosion resistance.

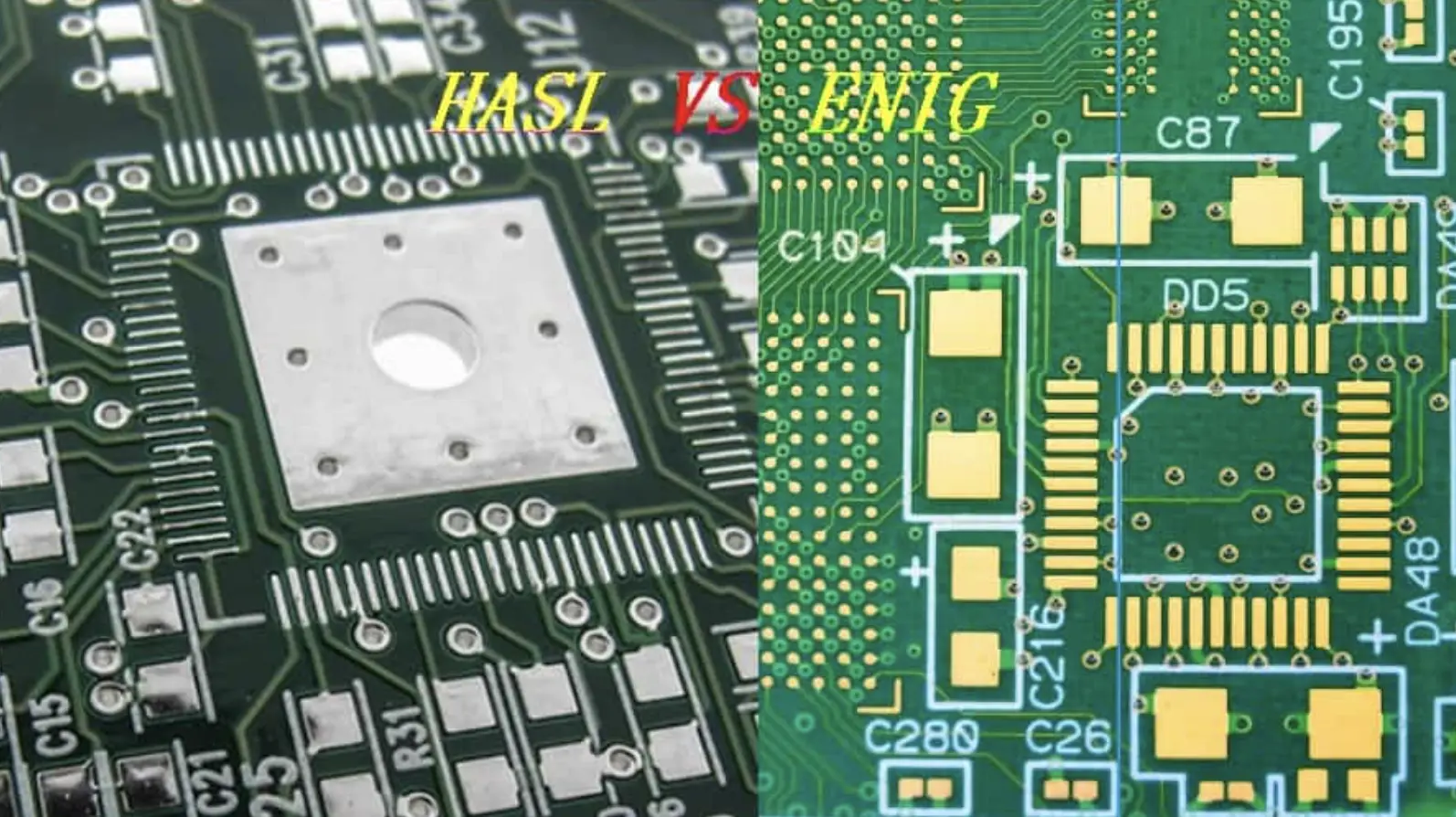

1. HASL (Hot Air Solder Leveling)

HASL is one of the oldest and most widely used surface finishes in PCB manufacturing. In this process, the board is dipped into a bath of molten solder (typically a tin-lead alloy or lead-free solder), and excess solder is blown off using hot air to create a uniform coating on the copper pads.

- Manufacturability Considerations: HASL is highly cost-effective and easy to apply, making it a popular choice for low-budget or high-volume projects. However, it can result in uneven surfaces, with variations in solder thickness that may cause issues for fine-pitch components (e.g., pads spaced less than 0.5 mm apart). This unevenness can affect placement accuracy during assembly.

- Soldering Performance: HASL provides excellent solderability due to its solder coating, ensuring strong and reliable joints during assembly. It performs well in wave soldering processes, often used for through-hole components.

- Corrosion Resistance: While HASL offers decent protection against oxidation, it is not the best choice for long-term corrosion resistance, especially in humid or harsh environments. The solder layer can degrade over time, exposing the underlying copper.

HASL is ideal for simpler designs or prototypes where cost is a primary concern, but it may not be suitable for high-density boards or applications requiring long shelf life.

2. ENIG (Electroless Nickel Immersion Gold)

ENIG is a two-layer finish consisting of a nickel barrier layer topped with a thin layer of gold. The nickel protects the copper from corrosion, while the gold ensures excellent solderability and prevents the nickel from oxidizing.

- Manufacturability Considerations: ENIG is more expensive than HASL due to the materials and process complexity. However, it provides a flat, uniform surface, making it ideal for fine-pitch components and high-density designs. It’s widely compatible with modern assembly techniques like surface-mount technology (SMT).

- Soldering Performance: ENIG offers outstanding soldering performance, with the gold layer dissolving into the solder during assembly to create strong, reliable joints. It supports multiple reflow cycles, which is critical for complex boards requiring rework.

- Corrosion Resistance: The nickel-gold combination provides excellent corrosion resistance, protecting the copper even in challenging environments. This makes ENIG a preferred choice for applications where reliability is paramount, such as in medical or aerospace devices.

ENIG is a go-to option for high-reliability applications, though its higher cost may not justify its use in budget-sensitive projects.

3. ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold)

ENEPIG builds on ENIG by adding a palladium layer between the nickel and gold. This extra layer enhances the finish’s durability and performance, making it suitable for even more demanding applications.

- Manufacturability Considerations: ENEPIG is one of the most expensive surface finishes due to the additional palladium layer and complex application process. Like ENIG, it provides a flat surface ideal for fine-pitch and high-density designs, but the cost often limits its use to specialized projects.

- Soldering Performance: ENEPIG excels in soldering performance, supporting both lead-free soldering and wire bonding. The palladium layer prevents issues like “black pad” (a defect in ENIG where nickel corrodes), ensuring consistent joint quality over multiple reflows.

- Corrosion Resistance: With three protective layers, ENEPIG offers superior corrosion resistance, making it ideal for harsh environments or applications requiring long-term reliability. It’s often used in military, aerospace, and high-end consumer electronics.

ENEPIG is the premium choice for projects where failure is not an option, though its high cost may be prohibitive for many applications.

4. Immersion Silver

Immersion silver involves depositing a thin layer of silver onto the copper pads through a chemical process. It’s a popular choice for applications requiring good solderability at a moderate cost.

- Manufacturability Considerations: Immersion silver is less expensive than ENIG or ENEPIG but more costly than HASL. It provides a flat surface suitable for fine-pitch components and is compatible with SMT assembly. However, it requires careful handling and storage to prevent tarnishing, as silver is prone to reacting with sulfur in the air.

- Soldering Performance: This finish offers excellent soldering performance, with high conductivity and strong solder joints. It’s particularly well-suited for high-frequency applications due to minimal signal loss (e.g., signal integrity at frequencies above 1 GHz).

- Corrosion Resistance: Immersion silver has moderate corrosion resistance. While it protects copper better than HASL, it can tarnish over time, especially if exposed to sulfur-containing environments. Proper packaging and storage can mitigate this issue.

Immersion silver strikes a balance between cost and performance, making it a versatile option for many mid-range applications.

Comparing PCB Surface Finishes: A Quick Reference

To help you visualize the differences between these finishes, here’s a comparison table based on key criteria:

| Surface Finish | Cost | Manufacturability | Soldering Performance | Corrosion Resistance | Best For |

|---|---|---|---|---|---|

| HASL | Low | Easy, uneven surface | Good | Moderate | Low-cost, simple designs |

| ENIG | Medium-High | Flat, fine-pitch compatible | Excellent | High | High-reliability, SMT |

| ENEPIG | High | Flat, fine-pitch compatible | Outstanding | Very High | Military, aerospace |

| Immersion Silver | Medium | Flat, fine-pitch compatible | Excellent | Moderate | High-frequency, mid-range |

Key Factors to Consider When Choosing a PCB Surface Finish

Selecting the right surface finish depends on several factors specific to your project. Here are the most important considerations to keep in mind:

1. Budget Constraints

If cost is a primary concern, HASL is often the most economical choice. However, for projects where reliability outweighs initial cost, investing in ENIG or ENEPIG can save money in the long run by reducing failures and rework.

2. Design Complexity

For boards with fine-pitch components or high-density layouts, a flat finish like ENIG, ENEPIG, or immersion silver is essential to ensure accurate component placement and soldering. HASL’s uneven surface can cause issues in these scenarios.

3. Environmental Conditions

If your PCB will operate in harsh conditions—such as high humidity, extreme temperatures, or exposure to chemicals—corrosion resistance becomes critical. ENIG and ENEPIG offer the best protection, while HASL and immersion silver may require additional protective measures.

4. Soldering Requirements

Consider the assembly process and soldering techniques used. For lead-free soldering or multiple reflow cycles, ENIG and ENEPIG perform best. Immersion silver is also a strong contender for high-frequency designs due to its conductivity.

5. Shelf Life and Storage

Some finishes, like immersion silver, are sensitive to tarnishing and require careful storage. If your boards will be stored for extended periods before assembly, a more durable finish like ENIG or ENEPIG might be a better fit.

How Surface Finish Impacts Manufacturability and Reliability

The surface finish you choose doesn’t just affect the final product—it plays a significant role during manufacturing and throughout the PCB’s lifecycle. Let’s break down these impacts:

Manufacturability Considerations

During production, the surface finish influences how easily components can be soldered and whether defects like misalignment or poor wetting occur. A flat, uniform finish reduces the risk of assembly errors, especially for automated pick-and-place machines handling components with tight tolerances (e.g., 0.4 mm pitch). Finishes like HASL, while cost-effective, can introduce variability that complicates high-precision manufacturing.

Soldering Performance

Soldering performance is a direct indicator of assembly quality. A good surface finish ensures that solder adheres properly to pads, forming strong electrical and mechanical connections. For example, ENIG and ENEPIG can withstand multiple thermal cycles (up to 260°C for lead-free soldering) without degrading, which is essential for complex boards requiring rework.

Corrosion Resistance for Long-Term Reliability

Over time, environmental factors can degrade a PCB’s performance if the surface finish fails to protect the copper. Corrosion can lead to increased contact resistance, signal loss, or complete failure. In applications where reliability is critical—such as automotive systems exposed to humidity levels above 80%—choosing a finish with high corrosion resistance like ENEPIG can prevent costly failures.

Conclusion: Making the Right Choice for Your PCB

Choosing the right PCB surface finish is a balancing act between cost, manufacturability, and reliability. HASL offers a low-cost solution for simpler designs but falls short in high-density or harsh-environment applications. ENIG and ENEPIG provide superior soldering performance and corrosion resistance, making them ideal for demanding projects, while immersion silver offers a middle ground with excellent conductivity for high-frequency designs.

By carefully evaluating your project’s requirements—such as budget, design complexity, and operating conditions—you can select a surface finish that ensures both ease of manufacturing and long-term reliability. At ALLPCB, we’re committed to helping you navigate these choices with expert guidance and high-quality manufacturing services tailored to your needs.

Take the time to weigh the pros and cons of each option, and don’t hesitate to consult with your manufacturing partner to ensure the best outcome for your PCB project. With the right surface finish, you’ll set the foundation for a successful and durable product.

ALLPCB

ALLPCB