When it comes to ensuring the quality of printed circuit boards (PCBs), choosing the right inspection method is critical. Between Automated Optical Inspection (AOI) and Manual Visual Inspection, which method truly delivers the best results for PCB quality control? In short, AOI often reigns supreme due to its speed, accuracy, and cost-effectiveness in high-volume production, while manual inspection remains valuable for small-scale or specialized projects where human judgment is key. In this detailed guide, we’ll break down the differences between automated optical inspection for PCBs and manual visual inspection for PCBs, compare their costs, and help you decide which method suits your needs best.

Introduction to PCB Quality Control

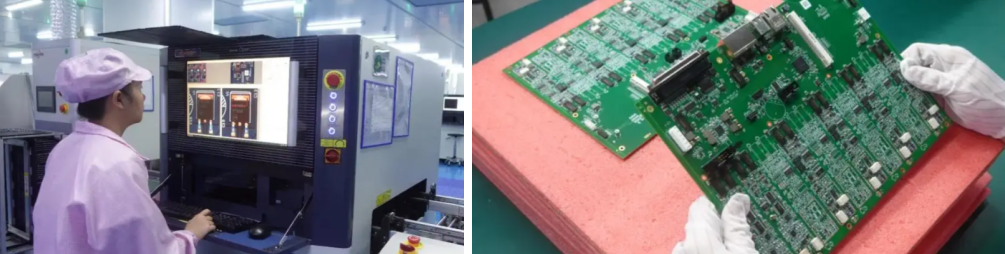

Quality control is the backbone of PCB manufacturing. A single defect in a PCB can lead to product failures, costly recalls, or even safety hazards in critical applications like medical devices or automotive systems. To prevent such issues, manufacturers rely on inspection methods to detect errors like soldering defects, missing components, or incorrect placements before the boards leave the factory.

Two primary methods dominate the field: Automated Optical Inspection (AOI) and Manual Visual Inspection. While both aim to ensure high-quality PCBs, they differ significantly in their approach, efficiency, and cost. This blog will dive deep into the pros and cons of each, focusing on long-tail keywords like "automated optical inspection PCB," "manual visual inspection PCB," and "AOI vs manual inspection cost" to provide a comprehensive comparison for engineers and manufacturers.

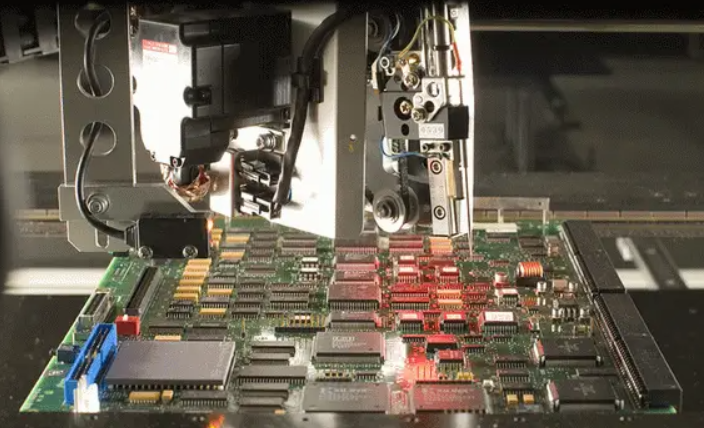

What is Automated Optical Inspection (AOI) for PCBs?

Automated Optical Inspection, commonly referred to as AOI, is a technology-driven method used to inspect PCBs for defects. It uses high-resolution cameras, advanced lighting, and image processing software to scan the surface of a PCB and identify issues with precision. AOI systems can detect a wide range of defects, including:

- Soldering issues like bridges or insufficient solder (down to 0.1 mm accuracy in some systems).

- Missing or misplaced components (even as small as 0402 size, which is 0.4 mm x 0.2 mm).

- Incorrect component orientation or polarity.

- Surface defects like scratches or contamination.

AOI systems work by capturing detailed images of the PCB and comparing them against a pre-programmed "golden board" or design file. Any deviation beyond acceptable tolerances—often as tight as ±0.05 mm for component placement—triggers an alert for further review. This method is incredibly fast, often inspecting a board in under 10 seconds, making it ideal for high-volume production.

Advantages of AOI in PCB Manufacturing

AOI offers several benefits that make it a go-to choice for modern PCB production lines:

- Speed: AOI can inspect hundreds of boards per hour, with some systems achieving speeds of up to 150 cm2 per second.

- Accuracy: With error detection rates often exceeding 95%, AOI minimizes the risk of defective boards slipping through.

- Consistency: Unlike human inspectors, AOI systems don’t suffer from fatigue, ensuring uniform results across long production runs.

- Data Collection: AOI systems generate detailed reports and store data for process improvement, helping manufacturers identify recurring issues.

Limitations of AOI

Despite its strengths, AOI isn’t perfect. It can struggle with:

- Hidden defects, such as issues beneath components or within multilayer boards, which may require X-ray inspection.

- Complex 3D structures or reflective surfaces that can interfere with image capture.

- High initial costs, with entry-level AOI systems starting at around $50,000 and advanced models exceeding $200,000.

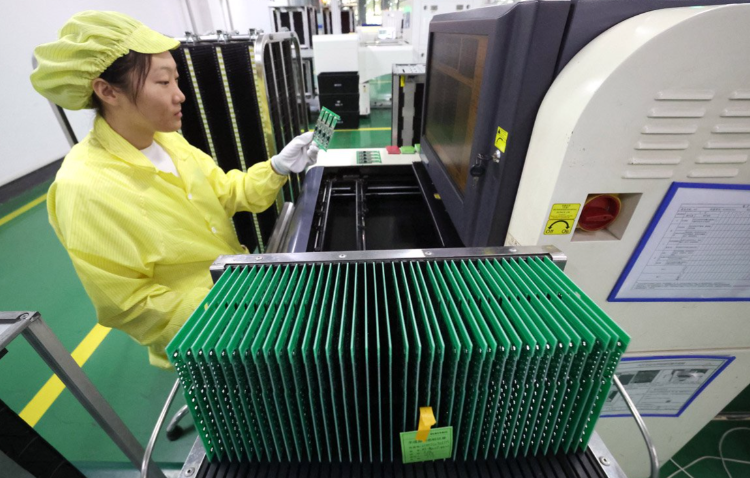

What is Manual Visual Inspection for PCBs?

Manual Visual Inspection involves trained technicians examining PCBs with the naked eye or using tools like magnifying glasses and microscopes. Inspectors look for visible defects such as poor soldering, misaligned components, or physical damage. This method has been a staple in PCB manufacturing for decades, especially in low-volume or prototype production.

In manual inspection, a technician might spend anywhere from 2 to 10 minutes per board, depending on its complexity. For intricate designs with hundreds of components, inspection can take even longer. Inspectors often follow a checklist based on the PCB design specifications to ensure no detail is overlooked.

Advantages of Manual Visual Inspection

Manual inspection shines in certain scenarios, offering unique benefits:

- Flexibility: Human inspectors can adapt to unique or non-standard PCB designs that AOI systems might not be programmed to handle.

- Low Initial Cost: This method requires minimal equipment, often just basic tools costing under $500, making it accessible for small-scale operations.

- Complex Defect Detection: Humans can sometimes spot subtle issues, like color discrepancies in solder masks or silkscreen errors, that AOI might miss.

Limitations of Manual Inspection

However, manual inspection comes with significant drawbacks:

- Speed: Inspecting a single board can take several minutes, making it impractical for high-volume production.

- Inconsistency: Human error and fatigue can lead to missed defects, with studies suggesting error rates as high as 10-20% after long shifts.

- Scalability: As production scales, the labor costs and time required for manual inspection grow exponentially.

AOI vs. Manual Inspection: Cost Comparison

One of the most critical factors in choosing between AOI and manual inspection is cost. Let’s break down the financial aspects of each method under the keyword "AOI vs manual inspection cost" to provide clarity for manufacturers weighing their options.

Initial Investment Costs

AOI systems require a significant upfront investment. Basic AOI machines start at approximately $50,000, while high-end models with advanced features like 3D imaging can cost over $200,000. Additionally, setup and training costs can add another $5,000 to $10,000, as operators need to learn programming and optimization, often requiring 2-5 days of hands-on training.

In contrast, manual inspection has a much lower entry barrier. Basic tools like magnifying glasses, microscopes, and lighting equipment can be acquired for under $500. For small operations, the only significant cost is labor, which varies based on location and expertise but often starts at $15-25 per hour for trained technicians.

Operational and Long-Term Costs

While AOI has a high initial cost, its operational expenses are lower in high-volume settings. Once set up, an AOI system can inspect thousands of boards with minimal additional costs beyond electricity and occasional maintenance (roughly $2,000-$5,000 per year). For a production run of 10,000 boards, the cost per board for AOI might drop to under $0.10, assuming the system is fully utilized.

Manual inspection, on the other hand, becomes expensive as production scales. If a technician inspects 50 boards per hour at a labor cost of $20 per hour, the cost per board is $0.40. For 10,000 boards, this translates to $4,000 in labor costs alone, not accounting for potential rework due to missed defects. Moreover, labor costs rise with longer shifts or the need for multiple inspectors, making manual inspection less viable for large-scale manufacturing.

Return on Investment (ROI)

AOI systems often deliver a strong ROI for manufacturers with consistent, high-volume production. Some industry reports suggest that AOI can achieve ROI within 14-18 months by reducing defect rates (up to 40% fewer errors) and minimizing rework costs. In contrast, manual inspection offers immediate cost savings for small batches (under 1,000 boards) but struggles to remain competitive as volumes increase.

Accuracy and Reliability: AOI vs. Manual Inspection

Beyond cost, the effectiveness of each method in detecting defects is a deciding factor. AOI systems consistently outperform manual inspection in terms of accuracy, with defect detection rates often above 95%. They excel at identifying minute issues, such as solder joint defects smaller than 0.1 mm, which are nearly impossible to spot with the naked eye.

Manual inspection, while valuable for certain subjective assessments (like aesthetic defects in solder masks), suffers from human limitations. Error rates can climb to 10-20% during long shifts due to fatigue or distraction. Additionally, manual inspection lacks the data logging capabilities of AOI, making it harder to track and address recurring issues in the production process.

When to Choose AOI for PCB Inspection

AOI is the preferred choice in the following scenarios:

- High-Volume Production: If you’re producing thousands of boards, AOI’s speed and consistency save time and money.

- Complex Designs: For densely populated PCBs with tiny components (e.g., 0201 size, 0.2 mm x 0.1 mm), AOI’s precision is unmatched.

- Quality-Critical Applications: In industries like aerospace or medical, where defect rates must be near zero, AOI ensures reliability.

When to Choose Manual Inspection for PCBs

Manual inspection still has its place, particularly in these situations:

- Small Batches or Prototypes: For low-volume runs or one-off designs, the cost of setting up an AOI system may not be justified.

- Non-Standard Designs: Unique or custom PCBs that don’t fit standard AOI programming benefit from human adaptability.

- Visual or Aesthetic Checks: Issues like silkscreen errors or color mismatches are often better assessed by a trained eye.

Combining AOI and Manual Inspection for Optimal Results

In many cases, the best approach isn’t choosing one method over the other but combining both. For instance, AOI can handle the bulk of defect detection in high-volume production, while manual inspection can serve as a secondary check for issues AOI might miss, such as hidden defects or aesthetic flaws. This hybrid strategy maximizes quality while balancing costs, ensuring no defect goes unnoticed.

Conclusion: Which Method Reigns Supreme?

So, which PCB quality control method reigns supreme—AOI or manual inspection? The answer depends on your specific needs. For high-volume, complex, or quality-critical production, Automated Optical Inspection for PCBs stands out as the superior choice due to its speed, accuracy, and long-term cost savings. However, for small-scale projects, prototypes, or unique designs, Manual Visual Inspection for PCBs offers flexibility and low initial costs that can’t be overlooked.

At ALLPCB, we understand the importance of delivering flawless PCBs tailored to your requirements. Whether you need the precision of AOI or the adaptability of manual inspection, we’re committed to providing top-tier quality control solutions. By weighing factors like production volume, design complexity, and budget, you can make an informed decision on the best inspection method—or combination of methods—for your next project.

ALLPCB

ALLPCB