Choosing the right PCB dielectric material is a critical step in designing a printed circuit board (PCB) that performs reliably and meets the needs of your application. A dielectric material is a non-conductive substance that insulates the conductive layers of a PCB, directly impacting its electrical, thermal, and chemical properties. To select the best material, you need to consider factors like dielectric constant, thermal conductivity, and resistance to environmental conditions. In this comprehensive guide, we’ll walk you through the essentials of PCB dielectric material selection, breaking down the key properties to evaluate and providing actionable insights to help you make an informed decision.

What Is a PCB Dielectric Material and Why Does It Matter?

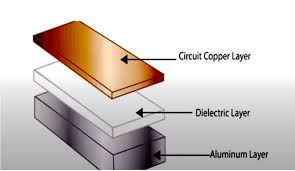

A PCB dielectric material is a non-conductive layer that sits between the conductive copper traces of a circuit board. Its primary role is to prevent electrical shorting while influencing how signals travel through the board. The right dielectric material ensures your PCB can handle the electrical demands of your design, withstand heat, and resist chemical degradation over time. Whether you’re working on a high-frequency application or a simple consumer device, the dielectric material you choose can make or break the performance and longevity of your board.

In the following sections, we’ll dive deep into the electrical, thermal, and chemical properties of common PCB dielectric materials. By understanding these factors, you’ll be equipped to select a material tailored to your specific needs.

Key Factors in Selecting a PCB Dielectric Material

When choosing a dielectric material for your PCB, you need to evaluate several critical properties. These include electrical performance, thermal behavior, and chemical stability. Let’s explore each of these in detail to help you understand their impact on your design.

1. Electrical Properties of PCB Dielectric Materials

The electrical properties of a dielectric material determine how well it supports signal integrity and prevents electrical interference. Here are the main factors to consider:

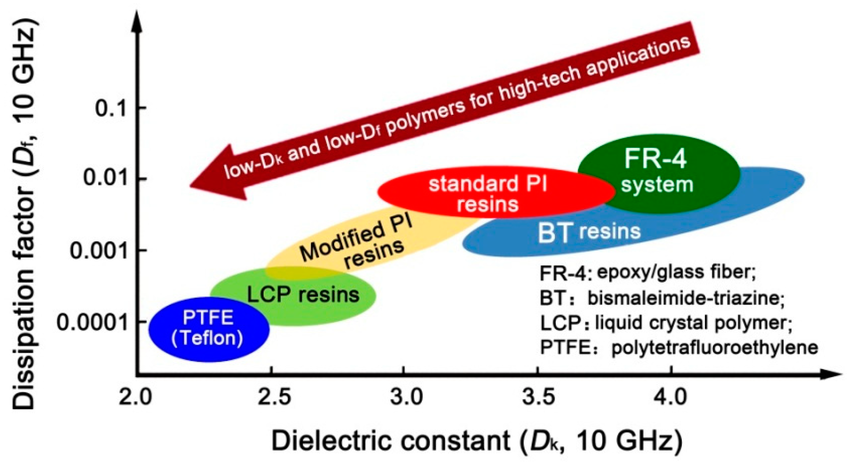

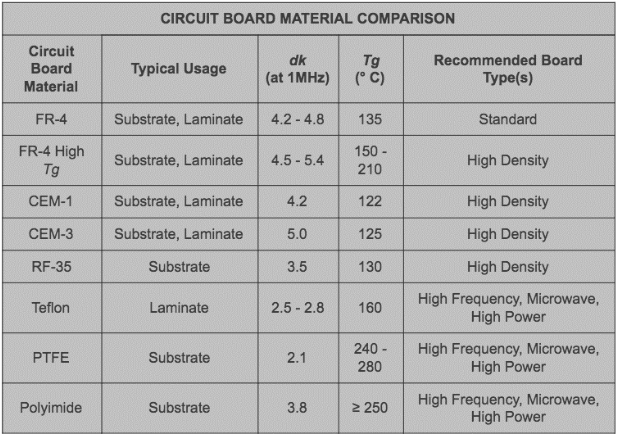

- Dielectric Constant (Dk): This measures how much a material can store electrical energy in an electric field. A lower Dk value (e.g., 2.2 for some high-frequency materials) means faster signal propagation, which is crucial for high-speed designs. For instance, in applications like 5G or RF circuits, a material with a Dk below 3.0 is often preferred to minimize signal delay. On the other hand, a higher Dk (e.g., 4.5 for standard FR-4) might be suitable for simpler, low-frequency designs.

- Dissipation Factor (Df): Also known as loss tangent, this indicates how much energy is lost as heat when a signal passes through the material. A low Df (e.g., 0.002 for some advanced laminates) is essential for high-frequency applications to reduce signal loss. For comparison, standard FR-4 might have a Df of 0.02, which is acceptable for many general-purpose boards but not ideal for high-speed signals.

- Insulation Resistance: Since dielectric materials are non-conductive, they must have high insulation resistance to prevent current leakage between layers. Materials with resistance values in the range of 10^12 ohms or higher are typically used to ensure reliability.

Matching the electrical properties to your application is vital. For example, if you’re designing a board for a high-speed communication device, prioritize materials with low Dk and Df values to maintain signal integrity over long traces.

2. Thermal Properties of PCB Dielectric Materials

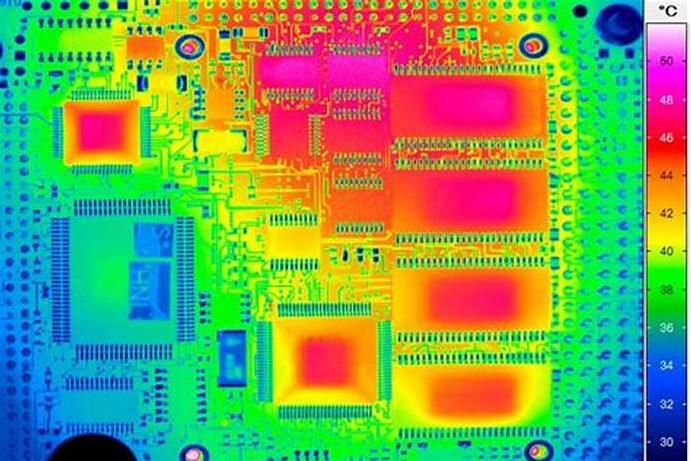

Thermal properties dictate how well a dielectric material can handle heat generated by components or environmental conditions. Poor thermal management can lead to warping, delamination, or failure of the PCB. Here’s what to look for:

- Thermal Conductivity (TC): This measures how effectively a material conducts heat away from hot spots. Materials with higher TC values (e.g., 1.0 W/m·K for some ceramic-filled options) are better for high-power applications where heat dissipation is critical. Standard FR-4, with a TC of about 0.3 W/m·K, may not suffice for high-heat designs.

- Coefficient of Thermal Expansion (CTE): CTE indicates how much a material expands or contracts with temperature changes. A mismatch between the CTE of the dielectric and other PCB layers (like copper, with a CTE of 17 ppm/°C) can cause stress and cracking. For high-reliability designs, choose a material with a CTE close to that of copper, ideally in the range of 15-20 ppm/°C.

- Glass Transition Temperature (Tg): Tg is the temperature at which a material shifts from rigid to flexible. A higher Tg (e.g., 170°C for some high-performance FR-4 variants) ensures the board remains stable during soldering or operation in hot environments. Standard FR-4 often has a Tg of around 130°C, which may not be suitable for extreme conditions.

For applications like automotive electronics or industrial equipment, where temperature fluctuations are common, selecting a material with excellent thermal properties can prevent premature failure and extend the lifespan of your PCB.

3. Chemical Properties of PCB Dielectric Materials

Chemical properties determine how well a dielectric material withstands exposure to moisture, solvents, and other environmental factors. This is especially important for PCBs used in harsh conditions. Key aspects include:

- Moisture Absorption: Materials with low moisture absorption (e.g., 0.1% for some PTFE-based options) are less likely to swell or degrade in humid environments. In contrast, standard FR-4 can absorb up to 0.2-0.4% moisture, which may affect electrical performance over time.

- Chemical Resistance: Some applications expose PCBs to cleaning solvents, oils, or corrosive substances. Materials like polyimide or PTFE offer excellent resistance to a wide range of chemicals, making them ideal for industrial or medical devices.

- Flammability Rating: Many dielectric materials are rated for fire resistance under standards like UL94. A rating of V-0 (the highest level) indicates the material self-extinguishes quickly, which is critical for safety in consumer electronics. Ensure your chosen material meets the necessary standards for your industry.

If your PCB will operate in a humid or chemically aggressive environment, prioritize materials with robust chemical properties to ensure long-term reliability.

Common PCB Dielectric Materials and Their Applications

With the key properties in mind, let’s review some widely used PCB dielectric materials and their suitability for different applications. This will help you narrow down your options based on your project requirements.

- FR-4: This is the most common dielectric material, made of woven fiberglass and epoxy resin. With a Dk of around 4.5, a Tg of 130-170°C, and moderate thermal and chemical properties, it’s ideal for general-purpose, low-cost designs. However, it’s less suitable for high-frequency or high-temperature applications.

- PTFE (Polytetrafluoroethylene): Known for its low Dk (around 2.1) and Df (0.0002), PTFE excels in high-frequency applications like RF and microwave circuits. It also offers excellent thermal stability and chemical resistance but comes at a higher cost.

- Polyimide: This high-performance material can withstand temperatures above 260°C and has strong chemical resistance. It’s often used in aerospace and military applications, though its higher moisture absorption (0.4%) requires careful consideration.

- Ceramic-Filled Materials: These combine ceramics with other substrates to achieve specific Dk values (ranging from 3.0 to 10.0) and high thermal conductivity. They’re perfect for high-power or high-frequency designs but are expensive and harder to process.

Choosing between these materials depends on balancing performance needs with budget constraints. For instance, FR-4 is a go-to for cost-sensitive projects, while PTFE or polyimide might be necessary for cutting-edge technology where performance trumps cost.

How to Match Dielectric Materials to Your Application

Now that you understand the properties and options available, here’s a step-by-step approach to selecting the right PCB dielectric material for your project:

- Define Your Electrical Requirements: Determine the frequency and speed of signals in your design. For high-speed or RF applications, opt for materials with low Dk and Df values. For simpler circuits, standard materials may suffice.

- Assess Thermal Demands: Consider the operating temperature range and heat dissipation needs. High-power or high-temperature environments call for materials with high Tg and thermal conductivity.

- Evaluate Environmental Conditions: If your PCB will face moisture, chemicals, or other harsh conditions, prioritize materials with low absorption and strong chemical resistance.

- Balance Cost and Performance: High-performance materials often come with a higher price tag. Weigh the benefits of advanced materials against your budget to find the best fit.

- Consult with Experts: If you’re unsure, collaborate with material suppliers or manufacturing partners to get recommendations tailored to your specific design.

By following these steps, you can systematically narrow down your choices and select a dielectric material that ensures optimal performance and reliability for your PCB.

Conclusion: Making an Informed Choice for Your PCB Dielectric Material

Selecting the right PCB dielectric material is a foundational decision that impacts the electrical, thermal, and chemical performance of your circuit board. By understanding key properties like dielectric constant, thermal conductivity, and moisture absorption, you can match a material to the unique demands of your application—whether it’s a low-cost consumer device or a high-frequency communication system. Remember to evaluate your project’s specific needs, from signal speed to environmental exposure, and balance those requirements with cost considerations.

Armed with this knowledge, you’re ready to make an informed choice that enhances the reliability and efficiency of your PCB design. A well-chosen dielectric material not only improves performance but also extends the lifespan of your product, ensuring it meets the expectations of end-users and industry standards alike.

ALLPCB

ALLPCB