When it comes to designing printed circuit boards (PCBs) for high-power applications, choosing the right substrate material is critical. Two popular options are Insulated Metal Substrate (IMS) PCBs and FR-4. But which one is better for your project? In short, IMS PCBs excel in thermal performance and heat dissipation, making them ideal for high-power and high-heat environments, while FR-4 is a cost-effective, versatile choice for less demanding applications. In this detailed guide, we'll compare IMS PCB vs FR4 thermal performance, metal core PCB vs FR4 heat dissipation, and explore the advantages of IMS PCB over FR4, as well as the FR4 limitations for high power and the insulated metal substrate benefits. Let's dive in to help you make an informed decision for your next project.

Understanding PCB Substrates: Why Material Matters

The substrate of a PCB acts as the foundation that supports the components and circuitry. It plays a significant role in determining the board's electrical performance, mechanical strength, and thermal management capabilities. For high-power applications like LED lighting, power supplies, or automotive electronics, heat dissipation is often a top concern. Poor thermal management can lead to component failure, reduced lifespan, or even safety hazards. This is where the choice between IMS PCB and FR-4 becomes crucial.

What is FR-4? A Quick Overview

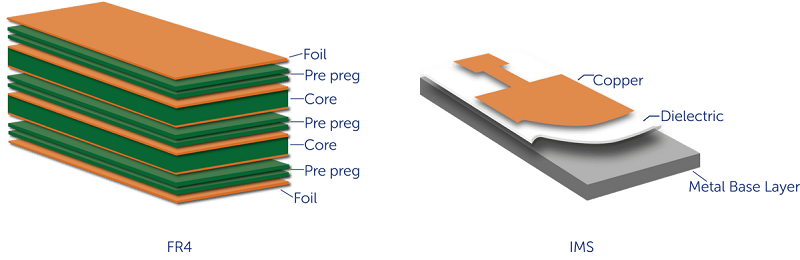

FR-4 is the most widely used PCB substrate material, made from woven fiberglass cloth with an epoxy resin binder. The "FR" stands for "Flame Retardant," indicating its ability to resist fire, which is essential for safety in electronics. FR-4 is known for its balance of cost, durability, and electrical insulation properties, making it a go-to choice for many standard applications.

However, FR-4 has limitations, especially when it comes to thermal conductivity. Its thermal conductivity is typically around 0.3 W/m·K, which means it struggles to transfer heat away from components efficiently. For high-power designs where components generate significant heat, this can be a major drawback.

Key Properties of FR-4

- Thermal Conductivity: 0.3 W/m·K (poor for high-heat scenarios)

- Temperature Resistance: Up to 130°C (standard grades)

- Cost: Low to moderate, making it budget-friendly

- Applications: General-purpose electronics, consumer devices, low-power circuits

What is IMS PCB? A Quick Overview

IMS PCB, or Insulated Metal Substrate PCB, is a type of metal core PCB designed specifically for superior thermal management. It consists of a metal base layer (usually aluminum or copper), a thin dielectric layer for insulation, and a copper circuit layer on top. The metal base acts as a heat sink, efficiently drawing heat away from components and dissipating it into the environment.

IMS PCBs are often used in applications where heat dissipation is critical, such as high-power LED lighting, motor drives, and power converters. With thermal conductivity values ranging from 1 to 8 W/m·K (depending on the dielectric material), IMS PCBs far outperform FR-4 in heat management.

Key Properties of IMS PCB

- Thermal Conductivity: 1-8 W/m·K (excellent for heat dissipation)

- Temperature Resistance: Can handle higher temperatures than FR-4

- Cost: Higher than FR-4 due to specialized materials and manufacturing

- Applications: High-power electronics, LED systems, automotive, industrial equipment

IMS PCB vs FR4 Thermal Performance: A Head-to-Head Comparison

One of the most critical factors in choosing between IMS PCB and FR-4 for high-power applications is thermal performance. Let's break down how these materials compare in terms of heat management.

Thermal Conductivity

As mentioned earlier, FR-4 has a thermal conductivity of about 0.3 W/m·K, which is insufficient for dissipating heat in high-power designs. In contrast, IMS PCBs offer thermal conductivity values between 1 and 8 W/m·K, depending on the specific materials used. This means IMS can transfer heat away from components much more effectively, preventing overheating and maintaining optimal performance.

Heat Dissipation Efficiency

In terms of metal core PCB vs FR4 heat dissipation, IMS PCBs have a clear edge. The metal base in IMS acts as a built-in heat sink, spreading heat across a larger area and reducing hot spots on the board. FR-4, lacking a conductive base, often requires additional heat sinks or cooling solutions, which add to the design's complexity and cost.

For example, in a high-power LED application, an IMS PCB can reduce the junction temperature of the LEDs by up to 20-30°C compared to FR-4 under the same operating conditions. Lower temperatures translate to better efficiency and a longer lifespan for the components.

Temperature Resistance

FR-4 can typically withstand temperatures up to 130°C before its properties degrade. Beyond this point, the epoxy resin may soften or break down, leading to mechanical and electrical failures. IMS PCBs, thanks to their metal base and specialized dielectric layers, can operate at higher temperatures without compromising structural integrity, making them more reliable in demanding environments.

Advantages of IMS PCB Over FR4

While FR-4 is suitable for many applications, IMS PCBs offer several distinct benefits, especially for high-power designs. Here are the key advantages of IMS PCB over FR4:

- Superior Thermal Management: As discussed, IMS PCBs excel in dissipating heat, making them ideal for applications where components generate significant thermal energy.

- Compact Design: Because IMS PCBs handle heat so well, they often eliminate the need for external heat sinks or fans, allowing for smaller, lighter designs.

- Enhanced Reliability: Lower operating temperatures reduce thermal stress on components, leading to improved reliability and longer product life.

- Better Mechanical Strength: The metal base provides additional rigidity, making IMS PCBs more durable in harsh environments like automotive or industrial settings.

- Energy Efficiency: By keeping components cooler, IMS PCBs help maintain optimal performance, reducing energy loss due to heat.

FR4 Limitations for High Power Applications

While FR-4 is a versatile and cost-effective material, it falls short in high-power scenarios. Here are the primary FR4 limitations for high power designs:

- Poor Thermal Conductivity: With a low thermal conductivity of 0.3 W/m·K, FR-4 struggles to manage heat in high-power circuits, leading to potential overheating.

- Need for Additional Cooling: To compensate for its poor heat dissipation, FR-4 often requires external cooling solutions like heat sinks or forced air systems, increasing design complexity and cost.

- Limited Temperature Range: FR-4 can only handle temperatures up to 130°C (or slightly higher with premium grades), which may not be sufficient for extreme conditions.

- Reduced Lifespan: Prolonged exposure to high temperatures can degrade FR-4's epoxy resin, leading to delamination or cracking over time.

For applications pushing beyond 10-15 watts of power dissipation per square inch, FR-4 often fails to meet thermal requirements, making IMS a better choice.

Insulated Metal Substrate Benefits for High-Power Designs

The insulated metal substrate benefits make IMS PCBs a preferred option for engineers working on high-power electronics. Let's explore these benefits in detail:

- Efficient Heat Spreading: The metal core evenly distributes heat, preventing localized hot spots that could damage components.

- Customizable Thermal Performance: IMS PCBs can be tailored with different metal bases (aluminum for cost-effectiveness, copper for higher conductivity) and dielectric thicknesses to meet specific thermal needs.

- Compatibility with High-Power Components: IMS substrates support components like high-current transistors, power LEDs, and IGBTs, which generate significant heat.

- Reduced Thermal Resistance: The thin dielectric layer in IMS PCBs minimizes thermal resistance between the components and the metal base, ensuring efficient heat transfer.

When to Choose IMS PCB Over FR-4

Deciding between IMS PCB and FR-4 depends on the specific requirements of your project. Here are some scenarios where IMS is the better choice:

- High-Power Applications: If your design involves power dissipation above 10-15 watts per square inch, IMS is essential for effective heat management.

- High-Temperature Environments: For applications exposed to temperatures above 130°C, IMS provides greater stability and reliability.

- Space Constraints: If your design needs to be compact and cannot accommodate external cooling solutions, IMS's built-in heat dissipation is a significant advantage.

- Long-Term Reliability: For products where longevity is critical, such as automotive or industrial equipment, IMS reduces thermal stress and extends component life.

On the other hand, FR-4 is suitable for low to medium-power applications where heat generation is minimal, and cost is a primary concern. It's an excellent choice for consumer electronics, prototyping, or designs with power dissipation below 5 watts per square inch.

Cost Considerations: IMS PCB vs FR-4

Cost is always a factor in PCB design. FR-4 is generally more affordable, with prices ranging from $0.50 to $2.00 per square inch for standard boards, depending on layer count and complexity. IMS PCBs, due to their specialized materials and manufacturing processes, are more expensive, often costing $2.00 to $5.00 per square inch or more.

However, the higher upfront cost of IMS can be offset by reduced expenses on additional cooling components and improved product reliability, which lowers maintenance and replacement costs over time.

Conclusion: Making the Right Choice for Your High-Power Application

Choosing between IMS PCB and FR-4 comes down to balancing thermal performance, cost, and application requirements. If your project involves high-power components or operates in high-heat environments, IMS PCBs offer unmatched heat dissipation and reliability, addressing the FR4 limitations for high power with their superior IMS PCB vs FR4 thermal performance. On the other hand, FR-4 remains a practical, budget-friendly option for less demanding designs.

By understanding the advantages of IMS PCB over FR4 and the specific insulated metal substrate benefits, you can make an informed decision that ensures optimal performance and longevity for your electronics. Whether you're designing for LED lighting, power converters, or automotive systems, selecting the right substrate is the first step to success.

ALLPCB

ALLPCB