When it comes to managing heat in printed circuit boards (PCBs), selecting the right heat sink attachment method is crucial for performance and reliability. Whether you're dealing with high-power components or surface-mount devices (SMDs), the way you secure a heat sink can impact thermal efficiency, assembly time, and long-term durability. In this guide, we'll explore popular heat sink attachment methods, including thermal tape, thermal adhesive, Z-clips, push pins, and other heat sink mounting techniques, to help you make an informed decision for your PCB design.

At ALLPCB, we understand the importance of thermal management in electronics. This comprehensive blog will break down each method, highlighting their pros, cons, and ideal use cases. Let's dive into the world of heat sink mounting and SMD heat sink attachment to find the best solution for your project.

Why Heat Sink Attachment Matters for Your PCB

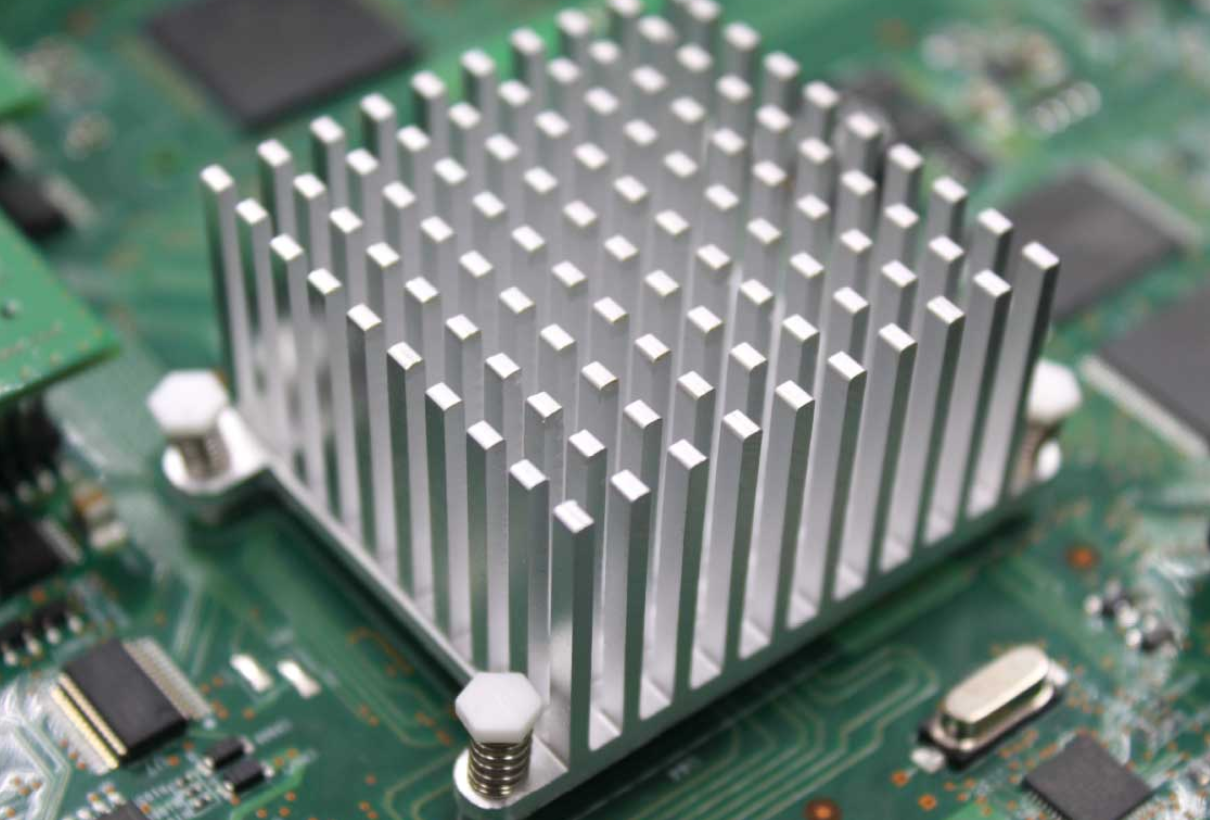

Heat sinks are essential for dissipating heat generated by components on a PCB, preventing overheating that can lead to performance issues or failure. However, a heat sink is only as effective as its attachment method. A poor connection can result in inadequate thermal transfer, causing hotspots and reducing the lifespan of your components. Choosing the right heat sink attachment method ensures optimal heat dissipation, maintains mechanical stability, and fits within your assembly process.

For instance, a high-power processor might generate up to 100 watts of heat, requiring a robust attachment like push pins or Z-clips for secure mounting and efficient cooling. On the other hand, smaller SMD components might only need a lightweight solution like thermal tape. Understanding the specific needs of your design is the first step in selecting the best heat sink mounting technique.

Overview of Heat Sink Attachment Methods

There are several heat sink attachment methods available, each with unique benefits and drawbacks. Below, we’ll explore the most common options, focusing on thermal tape, thermal adhesive, Z-clips, push pins, and other techniques used for heat sink mounting and SMD heat sink attachment.

1. Thermal Tape: A Quick and Easy Solution

Thermal tape is a pressure-sensitive adhesive tape designed to secure heat sinks to components while providing some level of thermal conductivity. It’s one of the simplest heat sink attachment methods, often used for lightweight heat sinks or low-power applications.

Advantages:

- Easy to apply: Just peel and stick, no tools required.

- Cost-effective: Thermal tape is inexpensive, making it ideal for budget-conscious projects.

- Non-permanent: Can be removed without damaging the PCB or component, though reapplication may reduce effectiveness.

Disadvantages:

- Limited thermal performance: Thermal tape typically has a thermal conductivity of 0.8-1.5 W/m·K, which is lower than other methods, making it unsuitable for high-power components.

- Weak mechanical strength: It may not hold up under vibration or mechanical stress.

- Not ideal for long-term use: Adhesive properties can degrade over time, especially under high temperatures.

Best Use Case: Thermal tape is perfect for small SMD heat sink attachment in low-power applications, such as LED drivers or microcontrollers generating less than 5 watts of heat.

2. Thermal Adhesive: A Permanent Bonding Option

Thermal adhesive, often in the form of epoxy or silicone-based compounds, offers a stronger and more permanent solution for heat sink mounting. These adhesives are formulated to provide both mechanical bonding and improved thermal conductivity compared to tape.

Advantages:

- Better thermal conductivity: Many thermal adhesives offer conductivity ratings of 1.5-3.0 W/m·K, improving heat transfer.

- Strong bond: Creates a durable connection that withstands vibration and mechanical stress.

- Versatile: Can be used on irregular surfaces or larger heat sinks.

Disadvantages:

- Permanent attachment: Removing a heat sink bonded with thermal adhesive can damage the PCB or component.

- Application challenges: Requires precise mixing and application to avoid air bubbles, which can reduce thermal performance.

- Curing time: Some adhesives need hours to set, slowing down assembly processes.

Best Use Case: Thermal adhesive is ideal for medium-power applications (10-30 watts) where a permanent bond is needed, such as attaching heat sinks to power regulators or small amplifiers on a PCB.

3. Z-Clips: Flexible and Reusable Mounting

Z-clips are metal clips shaped like the letter "Z" that secure heat sinks to a PCB without the need for adhesives. They apply pressure to hold the heat sink in place, often used in conjunction with thermal interface materials (TIMs) to enhance heat transfer.

Advantages:

- Reusable: Z-clips can be removed and reinstalled without damaging the PCB.

- Good thermal performance: When paired with TIMs, they ensure even pressure and effective heat dissipation.

- No curing time: Installation is quick, ideal for high-volume production.

Disadvantages:

- Requires PCB modifications: Holes or anchors must be designed into the board for clip attachment, which may affect layout or signal routing.

- Potential for uneven pressure: Poor installation can lead to inconsistent contact between the heat sink and component.

- Limited to specific designs: Not all heat sinks are compatible with Z-clips.

Best Use Case: Z-clips are well-suited for applications with heat dissipation needs of 20-50 watts, such as in networking equipment or industrial control systems.

4. Push Pins: Secure and Spring-Loaded Attachment

Push pins are spring-loaded fasteners that provide a secure and reliable method for heat sink mounting. They are commonly used in applications requiring frequent assembly and disassembly.

Advantages:

- Strong mechanical hold: Push pins provide consistent pressure, ensuring good thermal contact.

- Easy to install and remove: No tools are needed for basic push pins, speeding up assembly.

- Adaptable: Available in various sizes to fit different PCB hole diameters (typically 2.5-4.0 mm).

Disadvantages:

- Requires PCB holes: Like Z-clips, push pins need pre-drilled holes, which can complicate board design.

- Risk of damage: Incorrect installation may stress the PCB, potentially causing cracks or shorts.

- Not ideal for very small components: Push pins are better suited for larger heat sinks.

Best Use Case: Push pins excel in high-power applications (50-100 watts), such as cooling processors or power transistors in server boards or gaming hardware.

5. Other Heat Sink Mounting Techniques

Beyond the primary methods, there are additional heat sink attachment methods worth considering for specific scenarios:

- Captive Screws: These provide a robust and secure attachment, often used for heavy heat sinks in industrial applications. They require threaded holes in the PCB or a mounting bracket.

- Threaded Standoffs: These elevate the heat sink slightly above the PCB, useful for airflow optimization. They require precise alignment during assembly.

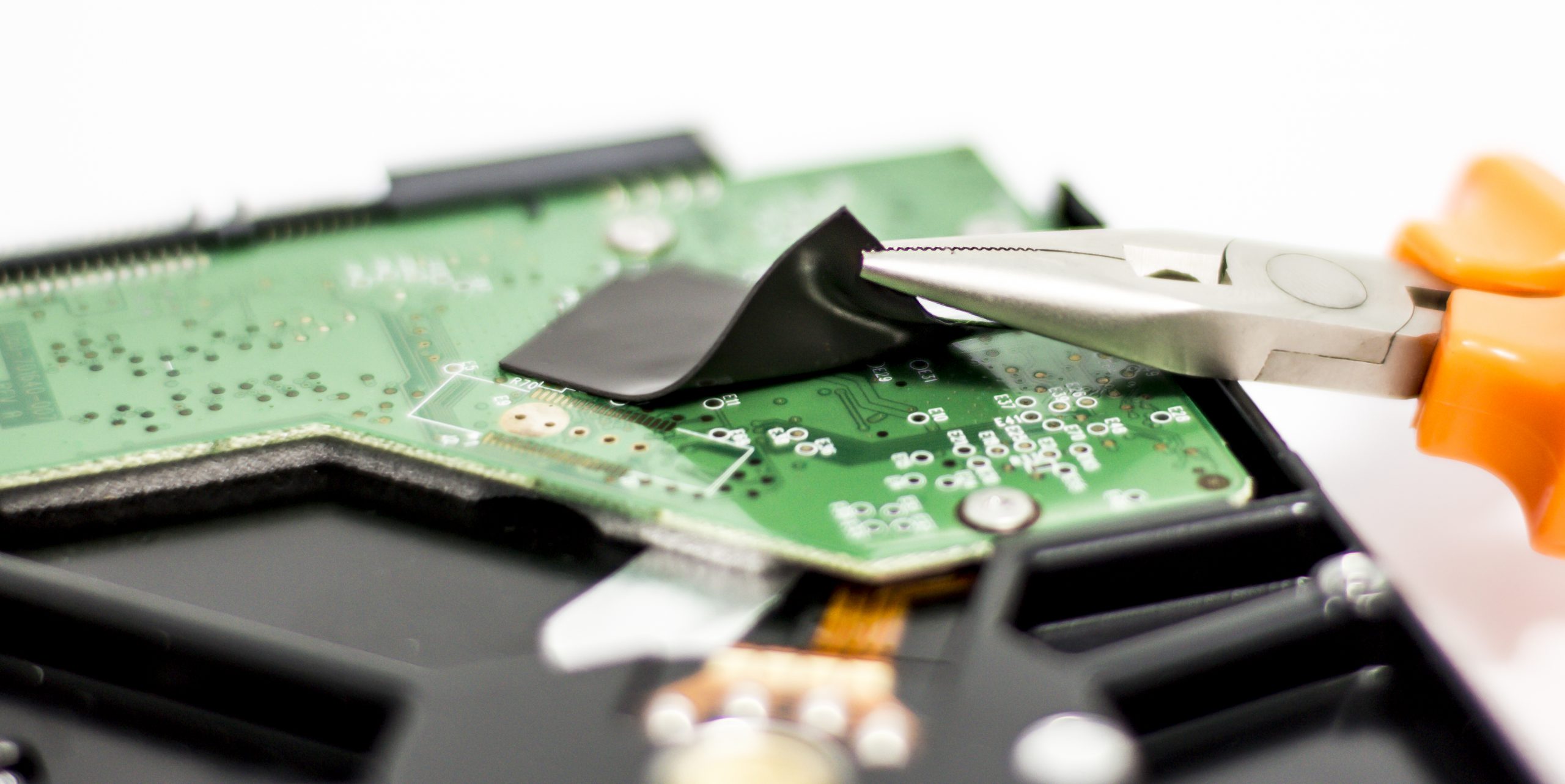

- SMD Heat Sink Attachment: For surface-mount devices, small heat sinks can be soldered directly onto pads or attached using thermal tape or adhesive. This method is common in compact designs like mobile devices, where space is limited.

Best Use Case: These techniques are tailored to niche applications, such as captive screws for rugged environments or SMD heat sink attachment for compact, low-power designs dissipating less than 10 watts.

Comparing Heat Sink Attachment Methods: A Quick Reference Table

To help you choose the right method for your project, here’s a comparison of the key heat sink attachment methods based on thermal performance, ease of installation, and ideal power range:

| Method | Thermal Conductivity (W/m·K) | Ease of Installation | Power Range (Watts) | Durability |

|---|---|---|---|---|

| Thermal Tape | 0.8-1.5 | Very Easy | 1-5 | Low |

| Thermal Adhesive | 1.5-3.0 | Moderate | 10-30 | High |

| Z-Clips | Depends on TIM (3.0-5.0) | Moderate | 20-50 | Moderate |

| Push Pins | Depends on TIM (3.0-5.0) | Easy | 50-100 | High |

This table serves as a starting point. Always consider your specific design constraints, such as space, cost, and thermal requirements, when making a decision.

Factors to Consider When Choosing a Heat Sink Attachment Method

Selecting the right heat sink mounting method for your PCB involves evaluating several factors:

- Thermal Requirements: Determine the heat dissipation needs of your components. High-power devices need methods with better thermal conductivity and secure mounting, like push pins or Z-clips paired with TIMs.

- Mechanical Stability: If your PCB will be subject to vibration or shock, opt for durable methods like thermal adhesive or captive screws.

- Assembly Process: Consider whether your production line can accommodate curing times (for adhesives) or requires quick installation (like thermal tape or push pins).

- PCB Design Constraints: Methods like Z-clips and push pins require holes or anchors, which may impact layout or signal integrity. Plan accordingly during the design phase.

- Cost: Budget constraints may push you toward cheaper options like thermal tape, but don’t sacrifice performance for savings in critical applications.

Tips for Effective Heat Sink Mounting

Regardless of the attachment method you choose, follow these best practices to maximize thermal performance:

- Use a thermal interface material (TIM) between the heat sink and component to fill microscopic gaps and improve heat transfer. Common TIMs have thermal conductivity ratings of 3.0-5.0 W/m·K.

- Ensure even contact pressure to avoid hotspots. Uneven mounting can reduce efficiency by up to 30%.

- Clean surfaces before attachment to remove dust or oils that could impede thermal conductivity.

- Test your setup under real-world conditions to verify that temperatures stay within safe limits (typically below 85°C for most components).

Conclusion: Finding the Best Heat Sink Attachment for Your PCB

Choosing the right heat sink attachment method for your PCB is a balancing act between thermal performance, mechanical stability, ease of assembly, and cost. Whether you opt for the simplicity of thermal tape, the permanence of thermal adhesive, the flexibility of Z-clips, the security of push pins, or specialized SMD heat sink attachment techniques, each method has its place in modern electronics design.

At ALLPCB, we’re committed to helping you achieve optimal thermal management in your projects. By understanding the strengths and limitations of each heat sink mounting approach, you can design PCBs that run cooler, last longer, and perform better. Evaluate your specific needs, consult the comparison table, and apply the tips provided to ensure success in your next build.

With the right heat sink attachment method, you’ll keep your components cool under pressure and maintain the reliability your applications demand. Let’s build smarter, cooler electronics together!

ALLPCB

ALLPCB