In the world of electronics manufacturing, Surface Mount Technology (SMT) assembly is a cornerstone for creating compact, efficient, and high-performance printed circuit boards (PCBs). However, the delicate nature of surface mount components demands robust protection to ensure reliability and longevity. This is where encapsulation resins come into play. If you're looking for solutions related to SMT assembly encapsulation, surface mount component protection, or PCB encapsulation for SMT, you're in the right place. Encapsulation resins shield SMT components and solder joints from environmental stressors like moisture, dust, and mechanical shock, ensuring your devices perform optimally over time.

In this comprehensive guide, we'll dive deep into the role of encapsulation resins in SMT assembly potting, explore their benefits for protecting SMT solder joints, and provide actionable insights on choosing the right resin for SMT. Whether you're an engineer, designer, or manufacturer, this blog will equip you with the knowledge to safeguard your SMT assemblies effectively.

What is SMT Assembly and Why Does It Need Protection?

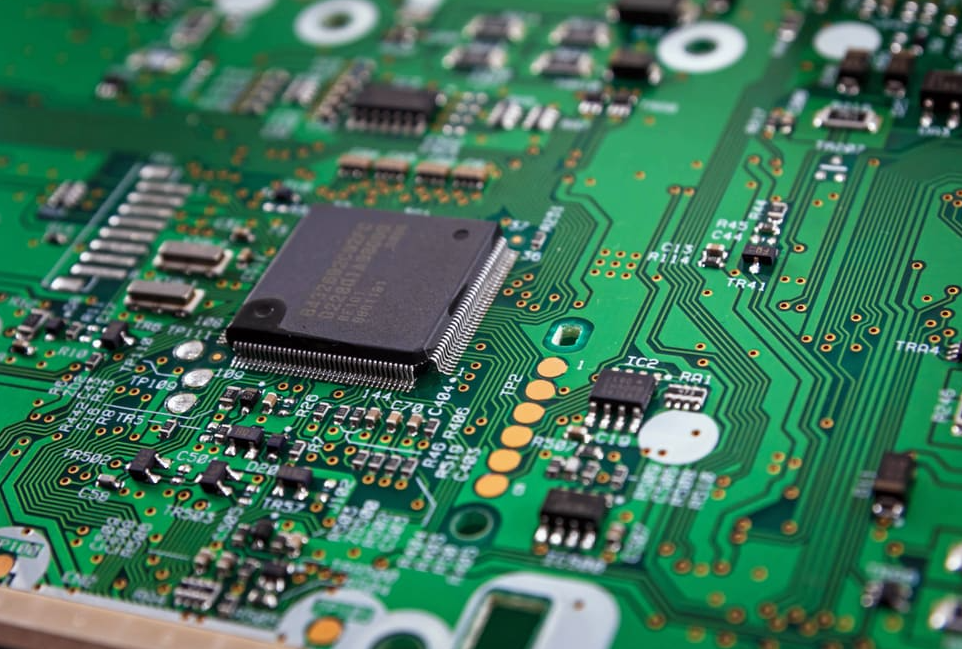

SMT assembly is a method used to mount electronic components directly onto the surface of a PCB. Unlike traditional through-hole technology, SMT components are smaller, have shorter leads or no leads at all, and allow for higher component density on a board. This results in smaller, lighter, and more efficient electronic devices. However, the compact nature of SMT components also makes them more vulnerable to environmental and mechanical damage.

Surface mount components are exposed to risks such as moisture ingress, thermal stress, vibration, and chemical exposure during operation. Without proper protection, these factors can lead to corrosion, cracked solder joints, or complete component failure. For instance, a study in the electronics industry found that up to 30% of PCB failures are due to environmental factors like humidity and temperature fluctuations. This is why surface mount component protection is critical, and encapsulation resins offer a reliable solution.

Understanding Encapsulation Resins for SMT Assembly

Encapsulation resins are specialized materials used to enclose and protect electronic components on a PCB. In the context of SMT assembly encapsulation, these resins are applied over the components and solder joints to form a protective barrier. Common types of resins include epoxy, silicone, polyurethane, and acrylic, each offering unique properties suited for different applications.

The primary purpose of using resin for SMT is to shield delicate components from environmental hazards. For example, epoxy resins are known for their excellent mechanical strength and resistance to chemicals, making them ideal for harsh industrial environments. Silicone resins, on the other hand, provide superior flexibility and thermal stability, which is beneficial for applications with frequent temperature changes.

Encapsulation can be applied through various methods, including potting (filling an enclosure with resin) and conformal coating (applying a thin protective layer). Both techniques are widely used in PCB encapsulation for SMT to ensure components remain secure and functional over extended periods.

Key Benefits of Using Encapsulation Resins in SMT Assembly

Using encapsulation resins in SMT assembly potting offers several advantages that enhance the durability and performance of electronic devices. Here are some of the key benefits:

- Moisture Resistance: Encapsulation resins create a waterproof barrier, preventing moisture from reaching SMT components. This is crucial in humid environments where corrosion can degrade solder joints and lead to short circuits.

- Thermal Protection: Resins help dissipate heat and protect components from thermal stress. For instance, silicone resins can withstand temperatures ranging from -40°C to 200°C, ensuring stability in extreme conditions.

- Mechanical Shock Absorption: Resins cushion components against vibrations and impacts, reducing the risk of cracked solder joints or detached components. This is especially important in automotive and aerospace applications.

- Chemical Resistance: Exposure to chemicals or solvents can damage SMT components. Encapsulation resins act as a shield, preventing chemical degradation.

- Electrical Insulation: Resins provide excellent dielectric properties, preventing electrical shorts and enhancing the overall safety of the PCB. Typical dielectric strength values for epoxy resins can range from 15 to 20 kV/mm, offering robust insulation.

How Encapsulation Resins Protect SMT Solder Joints

Solder joints in SMT assemblies are particularly vulnerable to stress and environmental factors. These tiny connections hold components in place and ensure electrical conductivity, but they can crack or corrode under harsh conditions. Protecting SMT solder joints is a critical aspect of ensuring the reliability of an electronic device.

Encapsulation resins stabilize solder joints by reducing mechanical stress caused by vibration or thermal expansion. For example, during thermal cycling, components and the PCB may expand or contract at different rates, putting strain on solder joints. A flexible resin like polyurethane can absorb this stress, preventing cracks. Additionally, by sealing out moisture and contaminants, resins prevent corrosion that could weaken the joints over time.

In high-reliability applications, such as medical devices or military equipment, protecting solder joints with encapsulation can mean the difference between a device functioning for years versus failing prematurely. Data from industry reports suggest that encapsulated solder joints can extend the lifespan of a PCB by up to 50% in harsh environments.

Choosing the Right Resin for SMT Assembly Encapsulation

Selecting the appropriate resin for SMT depends on the specific requirements of your application. Here are some factors to consider when choosing a resin for SMT assembly encapsulation:

- Environmental Conditions: If your device operates in a humid or corrosive environment, opt for a resin with high moisture and chemical resistance, such as epoxy. For high-temperature applications, silicone resins are a better choice due to their thermal stability.

- Mechanical Stress: In applications with frequent vibrations or impacts, choose a flexible resin like polyurethane to absorb shocks and protect components.

- Application Method: Consider whether you need full potting or a thin conformal coating. Potting provides maximum protection but adds more weight, while conformal coating is lighter and suitable for less demanding environments.

- Curing Time and Process: Some resins cure at room temperature, while others require heat or UV light. Ensure the curing process aligns with your manufacturing timeline and equipment capabilities. For instance, fast-curing resins can reduce production time by up to 20% in high-volume settings.

- Electrical Requirements: Verify the dielectric strength and insulation properties of the resin to ensure it meets the electrical demands of your PCB design.

Application Techniques for PCB Encapsulation in SMT

Applying encapsulation resins to SMT assemblies requires precision to ensure complete coverage without damaging components. Here are the two primary methods used for PCB encapsulation for SMT:

- Potting: This involves pouring or injecting resin into an enclosure or over the PCB to fully encase the components. Potting is ideal for maximum protection in rugged environments but can add weight and make repairs difficult.

- Conformal Coating: This method applies a thin layer of resin over the PCB using brushing, spraying, or dipping. Conformal coating is lighter and allows for easier rework, making it suitable for less harsh conditions.

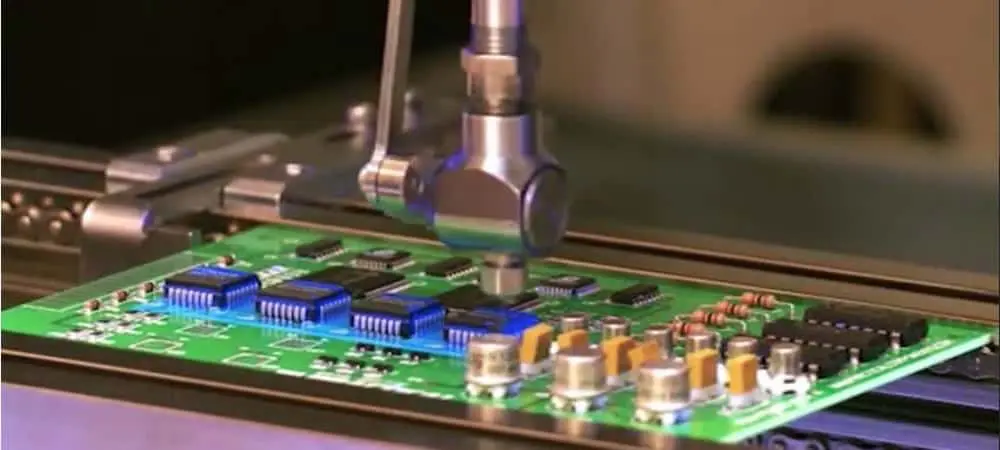

The choice of application method depends on the design of your PCB and the level of protection needed. For high-density SMT assemblies, automated dispensing systems are often used to apply resin with precision, ensuring coverage of even the smallest components without excess material.

Challenges and Best Practices in SMT Assembly Encapsulation

While encapsulation resins offer significant benefits, there are challenges to consider during implementation. For instance, improper application can lead to air bubbles trapped in the resin, which may compromise protection. Additionally, some resins may shrink during curing, putting stress on components.

To overcome these challenges, follow these best practices for SMT assembly potting:

- Prepare the PCB Surface: Clean the PCB thoroughly to remove dust, flux residues, or oils that could prevent proper adhesion of the resin.

- Use Proper Mixing Ratios: For two-part resins, follow the manufacturer’s mixing instructions precisely to ensure consistent curing and performance.

- Control Curing Conditions: Monitor temperature and humidity during curing to prevent defects like cracks or incomplete hardening.

- Test for Compatibility: Before full-scale production, test the resin with your specific components to ensure it doesn’t cause thermal or chemical stress.

By adhering to these practices, you can maximize the effectiveness of encapsulation and ensure long-term reliability for your SMT assemblies.

Real-World Applications of Encapsulation Resins in SMT Assembly

Encapsulation resins are used across various industries to protect SMT assemblies in demanding conditions. Here are a few examples:

- Automotive Electronics: In vehicles, SMT assemblies control critical systems like engine management and infotainment. Encapsulation resins protect these components from heat, vibration, and moisture, ensuring reliable performance. Resins used in automotive applications often need to withstand temperatures up to 150°C.

- Medical Devices: Portable medical equipment, such as glucose monitors, relies on SMT for compact designs. Encapsulation ensures these devices remain operational in humid or sterile environments.

- Industrial Equipment: SMT assemblies in industrial sensors and controllers are exposed to dust, chemicals, and extreme temperatures. Resins provide the durability needed for continuous operation.

Conclusion: Safeguarding Your SMT Assemblies with Encapsulation Resins

In the fast-paced world of electronics manufacturing, protecting delicate surface mount components is non-negotiable. Encapsulation resins offer a proven solution for surface mount component protection, safeguarding your SMT assemblies from environmental, thermal, and mechanical challenges. Whether you're focused on protecting SMT solder joints or seeking the right resin for SMT, understanding the properties and application methods of encapsulation materials is key to achieving reliable, long-lasting results.

By choosing the appropriate resin and following best practices for SMT assembly encapsulation, you can enhance the durability and performance of your PCBs, no matter the application. From automotive to medical devices, PCB encapsulation for SMT ensures your electronics stand the test of time in even the harshest conditions. Trust in the power of encapsulation to keep your designs secure and operational for years to come.

ALLPCB

ALLPCB