If you're looking for the best solder mask material for Surface Mount Technology (SMT) assembly, you're in the right place. Choosing the right solder mask material is critical for protecting your printed circuit board (PCB) from damage, ensuring reliable soldering, and maintaining long-term performance. In this guide, we'll dive deep into solder mask material selection, explore types like LPI solder mask, epoxy solder mask, and DFSM solder mask, and provide a detailed solder mask performance comparison to help you make an informed decision.

Whether you're an engineer designing a high-density PCB or a manufacturer optimizing assembly processes, understanding the nuances of solder mask materials can save you time, reduce defects, and improve product reliability. Let's break it down step by step with actionable insights and practical advice tailored for SMT assembly.

What Is a Solder Mask and Why Does It Matter for SMT Assembly?

A solder mask, also known as solder resist, is a thin protective layer applied to the copper traces of a PCB. Its primary role is to prevent oxidation of the copper, avoid solder bridges during assembly, and protect the board from environmental factors like moisture and dust. In SMT assembly, where components are densely packed and precision is key, the solder mask ensures that solder only adheres to designated pads, reducing the risk of short circuits.

Without a proper solder mask, copper traces can corrode over time, leading to electrical failures. Additionally, during the reflow soldering process common in SMT, misplaced solder can create unintended connections between components. The right solder mask material enhances insulation resistance, withstands high temperatures (often up to 260°C during reflow), and ensures long-term durability. With this foundation in mind, let's explore the different types of solder mask materials available for SMT applications.

Types of Solder Mask Materials for SMT Assembly

Not all solder masks are created equal. The material you choose depends on your PCB design, assembly process, and performance requirements. Below, we’ll cover the most common types used in SMT assembly, focusing on their properties, applications, and suitability.

1. LPI Solder Mask (Liquid Photoimageable Solder Mask)

LPI solder mask is one of the most widely used materials in modern PCB manufacturing, especially for SMT assembly. This liquid-based mask is applied through a screen-printing or spray-coating process and then cured using UV light to create precise openings for solder pads.

- Advantages: LPI offers high resolution, making it ideal for fine-pitch components common in SMT. It can achieve a thickness of 0.8 to 1.2 mils (20-30 micrometers), ensuring accurate coverage even on complex designs. It also provides excellent adhesion to the PCB surface.

- Applications: Best for high-density boards with small pad spacing, such as those used in smartphones and IoT devices.

- Limitations: LPI can be less durable under extreme thermal stress compared to other materials and may require careful handling to avoid cracking during multiple reflow cycles.

For SMT assembly, LPI is often the go-to choice due to its precision and cost-effectiveness for high-volume production.

2. Epoxy Solder Mask

Epoxy solder mask is a traditional material known for its robustness and affordability. It is typically applied as a liquid through screen printing and cured thermally. This type of mask has been a staple in PCB manufacturing for decades.

- Advantages: Epoxy masks are highly resistant to chemicals and mechanical stress, making them suitable for harsh environments. They can withstand temperatures up to 280°C, which is beneficial for multiple reflow processes in SMT assembly.

- Applications: Commonly used in industrial electronics and automotive PCBs where durability is critical.

- Limitations: Epoxy masks lack the precision of LPI, with a typical thickness of 1.5 to 2.0 mils (38-50 micrometers), which can be problematic for fine-pitch SMT components. The application process is also less consistent for intricate designs.

While epoxy is less common in cutting-edge SMT designs, it remains a reliable option for less complex boards with larger components.

3. DFSM Solder Mask (Dry Film Solder Mask)

DFSM solder mask, or dry film solder mask, is a photoimageable film applied as a solid sheet to the PCB surface. It is laminated onto the board and then exposed to UV light to define solder pad areas before being developed and cured.

- Advantages: DFSM provides uniform thickness (typically 1.0 to 1.5 mils or 25-38 micrometers) and excellent edge definition, making it suitable for SMT boards with tight tolerances. It also offers good resistance to thermal and mechanical stress.

- Applications: Ideal for high-reliability applications like aerospace and medical devices where precision and durability are non-negotiable.

- Limitations: The lamination process can be more expensive and time-consuming compared to liquid-based masks like LPI. It may also struggle with very complex board geometries.

DFSM is a premium choice for SMT assembly when precision and reliability outweigh cost considerations.

Solder Mask Material Selection: Key Factors for SMT Assembly

When it comes to solder mask material selection for SMT assembly, there’s no one-size-fits-all solution. Your choice should be guided by specific project requirements and performance needs. Here are the critical factors to consider:

- Board Complexity: For high-density SMT boards with fine-pitch components (e.g., pad spacing below 0.5 mm), LPI or DFSM is preferable due to their precision. Epoxy may suffice for simpler designs with larger components.

- Thermal Resistance: SMT assembly often involves reflow soldering at temperatures between 240°C and 260°C. Ensure the solder mask can handle multiple cycles without degrading. Epoxy and DFSM typically offer better thermal resistance than standard LPI formulations.

- Environmental Durability: If your PCB will be exposed to harsh conditions (e.g., high humidity or chemical exposure), prioritize materials like epoxy for their robust protective properties.

- Cost Constraints: LPI and epoxy are generally more cost-effective for mass production, while DFSM may increase expenses due to its specialized application process.

- Insulation Resistance: For high-frequency SMT applications, choose a mask with high dielectric strength (e.g., LPI or DFSM) to prevent signal interference. Typical insulation resistance values for quality solder masks range from 10^12 to 10^14 ohms.

By aligning your solder mask choice with these factors, you can optimize both the performance and manufacturability of your SMT assembly process.

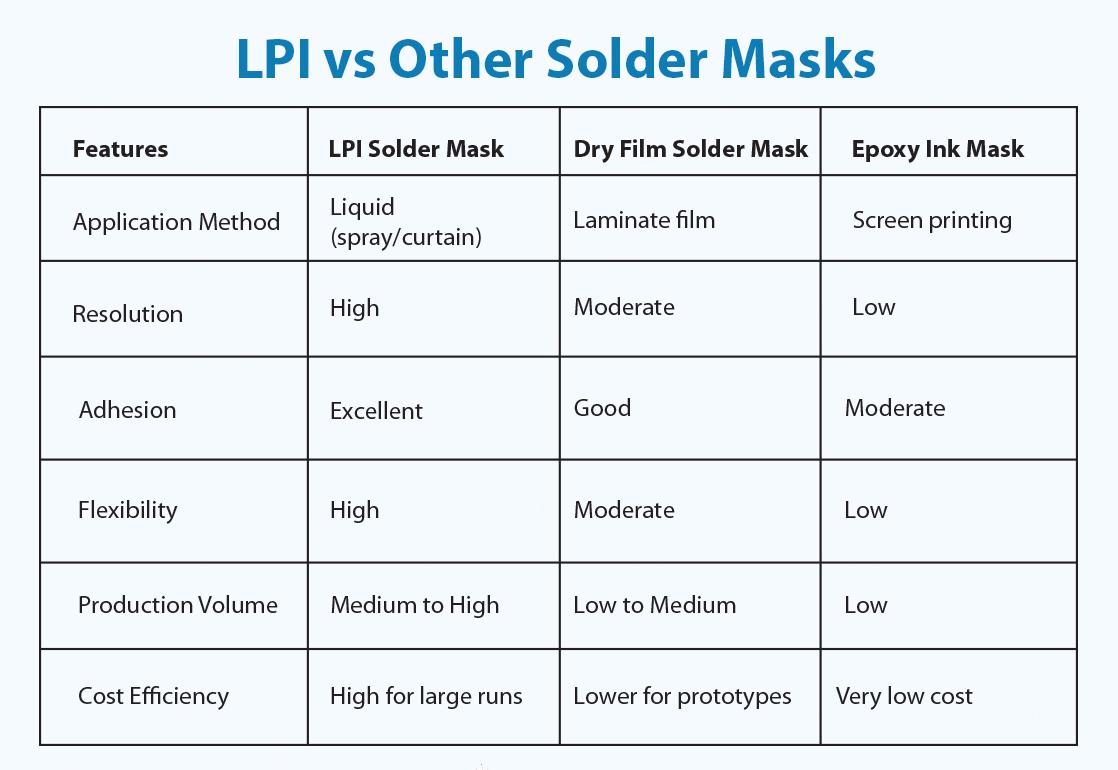

Solder Mask Performance Comparison: Which Material Wins?

To help you make an informed decision, let’s conduct a solder mask performance comparison across key metrics relevant to SMT assembly. The data below is based on typical industry standards and material properties.

| Material | Precision (Fine-Pitch Capability) | Thermal Resistance (°C) | Thickness Range (mils) | Cost | Durability |

|---|---|---|---|---|---|

| LPI Solder Mask | Excellent (suitable for 0.3 mm pitch) | Up to 260°C | 0.8 - 1.2 | Low to Medium | Moderate |

| Epoxy Solder Mask | Moderate (best for >0.8 mm pitch) | Up to 280°C | 1.5 - 2.0 | Low | High |

| DFSM Solder Mask | Excellent (suitable for 0.3 mm pitch) | Up to 270°C | 1.0 - 1.5 | Medium to High | High |

Key Takeaways from the Comparison:

- For ultra-fine pitch SMT components, both LPI and DFSM outperform epoxy due to their precision and thinner application.

- Epoxy excels in thermal resistance and durability, making it a strong choice for rugged applications despite its limitations in precision.

- DFSM strikes a balance between precision and durability but comes at a higher cost, which may not be justified for all projects.

Ultimately, the best material depends on your specific SMT assembly needs. For high-density consumer electronics, LPI is often the most practical. For industrial or automotive applications, epoxy or DFSM might be worth the investment.

Best Practices for Applying Solder Mask in SMT Assembly

Even the best solder mask material can underperform if not applied correctly. Here are some best practices to ensure optimal results during SMT assembly:

- Ensure Clean Surfaces: Before applying the solder mask, thoroughly clean the PCB to remove contaminants like dust or oil. This improves adhesion and prevents defects.

- Control Thickness: Overly thick solder masks can interfere with component placement in SMT, while overly thin masks may not provide adequate protection. Stick to the recommended thickness ranges for your chosen material.

- Verify Alignment: Misaligned solder mask openings can expose unintended copper areas or cover solder pads, leading to assembly failures. Use precise imaging and alignment techniques, especially for LPI and DFSM.

- Test for Compatibility: Ensure the solder mask material is compatible with your soldering flux and cleaning agents. Incompatible materials can degrade during assembly, reducing reliability.

- Monitor Curing Conditions: Improper curing (e.g., insufficient UV exposure for LPI or incorrect temperature for epoxy) can weaken the mask. Follow manufacturer guidelines for curing times and conditions.

By adhering to these practices, you can maximize the protective and functional benefits of your chosen solder mask material.

How Solder Mask Impacts SMT Assembly Yield and Reliability

In SMT assembly, yield and reliability are paramount. A poorly chosen or applied solder mask can lead to defects like solder bridging, insufficient insulation, or thermal cracking. Here's how the right solder mask contributes to success:

- Reduces Solder Bridges: Precision masks like LPI and DFSM ensure solder only flows to intended areas, minimizing shorts on densely packed SMT boards.

- Enhances Thermal Stability: Materials like epoxy and DFSM withstand repeated reflow cycles without degrading, maintaining board integrity over time.

- Protects Against Environmental Damage: A robust solder mask prevents moisture ingress and oxidation, extending the lifespan of SMT-assembled PCBs in real-world conditions.

Studies in PCB manufacturing suggest that proper solder mask application can improve first-pass yield by up to 15% in high-volume SMT production by reducing common defects. Investing in the right material and process is a small price to pay for significant long-term gains.

Conclusion: Making the Right Choice for Your SMT Assembly

Selecting the ideal solder mask material for SMT assembly doesn't have to be overwhelming. By understanding the strengths and limitations of LPI solder mask, epoxy solder mask, and DFSM solder mask, you can make a decision that aligns with your project's needs. Whether you prioritize precision for fine-pitch components, durability for harsh environments, or cost-effectiveness for mass production, there's a material suited to your goals.

Remember to consider factors like thermal resistance, board complexity, and environmental demands during solder mask material selection. Use the solder mask performance comparison provided to weigh your options and follow best practices during application to ensure optimal results. With the right solder mask, you'll enhance the reliability and yield of your SMT assembly, delivering high-quality PCBs that stand the test of time.

At ALLPCB, we're committed to supporting your PCB manufacturing journey with expert guidance and top-tier solutions. Dive into the details, choose wisely, and watch your SMT projects thrive.

ALLPCB

ALLPCB