Are you looking for the best method to cure and reduce curing time for conformal coating on printed circuit boards (PCBs)? If so, UV cure technology stands out as a fast and efficient solution, often hardening coatings in mere seconds. Alongside UV light conformal coating, other fast curing coating techniques like thermal and moisture curing offer viable alternatives depending on your specific needs. In this comprehensive guide, we'll explore how to use UV light to cure boards fast, dive into various curing methods, and provide actionable insights to help you optimize your PCB production process.

Why Curing Time Matters in PCB Manufacturing

In the fast-paced world of electronics manufacturing, time is money. The curing process for conformal coatings—protective layers applied to PCBs to shield them from moisture, dust, and other environmental factors—can be a bottleneck if not optimized. Traditional curing methods can take hours or even days, slowing down production and increasing costs. Reducing curing time without compromising quality is crucial for maintaining efficiency and meeting tight deadlines.

Whether you're working on consumer electronics, automotive systems, or medical devices, finding a fast curing coating solution can significantly boost your throughput. Let’s explore the leading methods, starting with UV light conformal coating, which is often hailed as the best method to cure and reduce curing time for conformal coating.

What is UV Light Conformal Coating and How Does It Work?

UV light conformal coating involves using ultraviolet (UV) light to cure or harden a liquid coating applied to a PCB. This process, known as photopolymerization, transforms the liquid into a solid protective film almost instantly—often in just 5 to 30 seconds, depending on the coating material and UV light intensity. This makes it one of the fastest curing methods available.

The process is simple: a UV-curable coating is applied to the PCB via spraying, brushing, or dipping. The board is then exposed to UV light, typically in the UVA or UVB spectrum (wavelengths between 320-400 nm), which triggers a chemical reaction in the coating. This reaction forms a durable, protective layer that shields the PCB from environmental damage.

One major advantage of UV curing is its environmental friendliness. Unlike solvent-based coatings, UV-curable materials often contain no volatile organic compounds (VOCs), reducing harmful emissions. Additionally, the energy efficiency of UV systems, especially modern UV LED setups, cuts down on power consumption compared to older methods.

Key Benefit: UV curing systems can achieve full cure in under a minute, compared to hours for thermal curing or days for moisture curing. This makes it ideal for high-volume production environments where speed is essential.

Comparing UV Cure to Other Fast Curing Coating Methods

While UV light conformal coating is a top choice for speed, it’s not the only option. Let’s compare it with other common curing techniques to help you decide the best method to cure and reduce curing time for conformal coating in your operations.

1. Thermal Curing

Thermal curing uses heat to harden the conformal coating. The PCB is placed in an oven or exposed to hot air, typically at temperatures between 60°C and 120°C (140°F to 248°F), for 30 minutes to several hours. While this method is widely used and reliable, it’s much slower than UV curing and consumes more energy due to the heating process.

Pros: Works well for a wide range of coating materials and is effective for complex board designs where UV light might not reach shadowed areas.

Cons: Longer curing times and higher energy costs make it less ideal for fast-paced production.

2. Moisture Curing

Moisture curing relies on ambient humidity to trigger the hardening process. Once the coating is applied, it reacts with water vapor in the air, curing over several hours to a full day (typically 24-48 hours at 50% relative humidity). This method is often used for silicone-based coatings.

Pros: No special equipment is needed, making it a low-cost option for smaller operations.

Cons: Curing time is highly dependent on environmental conditions, and it’s far slower than UV or thermal methods.

3. Dual-Cure Systems

Some coatings combine UV curing with a secondary mechanism, such as moisture or heat, to ensure complete hardening in areas where UV light can’t penetrate (e.g., under tall components). While the UV portion cures in seconds, the secondary process might take longer—up to 24 hours for full strength.

Pros: Ensures thorough curing even on complex PCB layouts.

Cons: The secondary cure slows down the overall process compared to pure UV curing.

How to Use UV Light to Cure Boards Fast: Step-by-Step Guide

Implementing UV light conformal coating in your production line can drastically cut curing times. Here’s a practical guide on how to use UV light to cure boards fast, ensuring optimal results.

Step 1: Choose the Right UV-Curable Coating

Select a coating compatible with UV curing. Common materials include acrylics and urethanes designed for rapid photopolymerization. Check the manufacturer’s specifications for recommended UV wavelength and exposure time—most require UVA light at 365 nm for best results.

Step 2: Apply the Coating Evenly

Use a spray system, brush, or automated dipping machine to apply a uniform layer of coating, typically 25-75 micrometers thick. Uneven application can lead to incomplete curing or weak spots in the protective layer.

Step 3: Set Up the UV Curing System

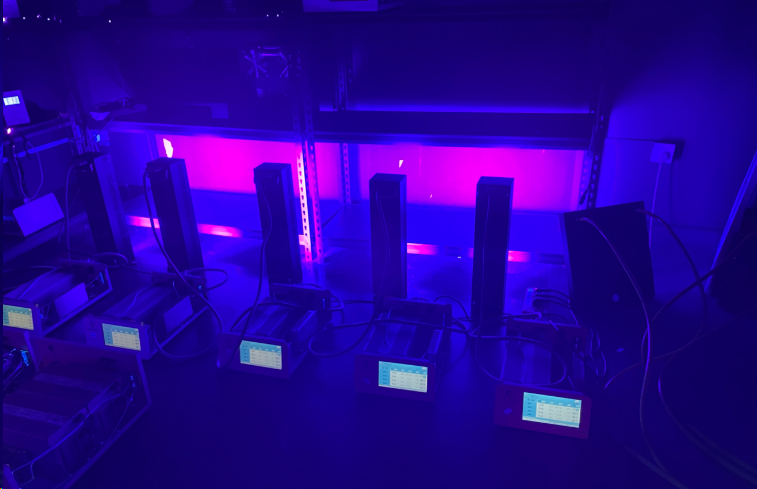

Use a UV curing machine equipped with either mercury arc lamps or UV LED lights. Mercury lamps emit a broad spectrum of UV light (including UVC, which is powerful but potentially harmful), while UV LEDs are more energy-efficient and focused on specific wavelengths like 365 nm or 395 nm. Position the light source 2-6 inches above the PCB for optimal exposure, and ensure the intensity is between 100-1000 mW/cm2, depending on the coating requirements.

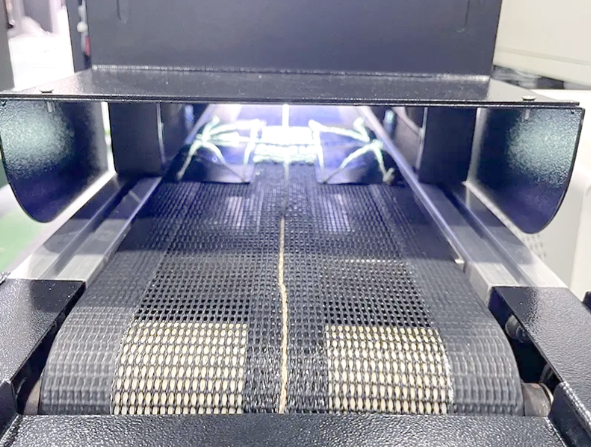

Step 4: Expose the PCB to UV Light

Pass the coated PCB under the UV light for the recommended time—often just 5-30 seconds. For conveyorized systems, adjust the belt speed to match the exposure duration. Ensure no areas are shadowed by tall components; if shadowing occurs, consider a dual-cure coating.

Step 5: Inspect the Cured Coating

After curing, check the PCB for uniform hardness and adhesion. Use a thickness gauge to confirm the coating is within the desired range (e.g., 25-75 micrometers) and visually inspect for uncured spots, which may appear tacky or glossy.

Tip: Modern UV LED systems are gaining popularity due to their longer lifespan (up to 20,000 hours compared to 1,000 hours for mercury lamps) and lower heat output, reducing the risk of thermal damage to sensitive components.

Benefits of UV Light Conformal Coating for PCB Protection

UV curing isn’t just about speed—it offers several advantages that make it a top choice for PCB manufacturers aiming for efficiency and reliability.

- Rapid Curing: As mentioned, UV curing can harden coatings in under a minute, compared to hours or days for other methods.

- Enhanced Durability: UV-cured coatings often provide superior resistance to moisture, chemicals, and thermal shock, with dielectric strengths up to 1,500 volts/mil for some materials.

- Precision Control: UV systems allow precise control over curing time and intensity, ensuring consistent results across batches.

- Reduced Footprint: UV curing equipment is often compact, saving valuable floor space in manufacturing facilities compared to large thermal ovens.

- Environmental Benefits: With no VOCs and lower energy use (especially with UV LEDs), this method aligns with stricter environmental regulations.

Challenges and Solutions with UV Curing

While UV light conformal coating is highly effective, it’s not without challenges. Here are common issues and how to address them.

Challenge 1: Shadowing Effect

Tall components on a PCB can block UV light, leaving some areas uncured. This is especially problematic in densely populated boards.

Solution: Use a dual-cure coating that combines UV and moisture or heat curing to ensure full protection. Alternatively, adjust the angle of the UV light or use multiple light sources to minimize shadows.

Challenge 2: Equipment Cost

Initial investment in UV curing systems can be high, with industrial setups costing between $5,000 and $50,000 depending on scale and features.

Solution: Start with a smaller, modular system for low-volume production and scale up as needed. The long-term savings in time and energy often offset the upfront cost.

Challenge 3: Safety Concerns

UV light, especially in the UVC range, can be harmful to skin and eyes if not properly shielded.

Solution: Equip curing stations with protective enclosures and ensure operators wear UV-resistant gloves and goggles. Opt for UV LED systems, which emit less harmful radiation.

Choosing the Best Method to Cure and Reduce Curing Time for Conformal Coating

Deciding on the right curing method depends on several factors: production volume, PCB complexity, budget, and environmental considerations. Here’s a quick decision guide:

- High-Volume Production: UV light conformal coating is the best choice due to its speed (curing in seconds) and scalability with conveyor systems.

- Complex Boards: Consider dual-cure systems to handle shadowed areas if UV alone isn’t sufficient.

- Low Budget: Moisture curing might be a starting point, though it sacrifices speed for cost savings.

- Energy Efficiency: UV LED curing offers the best balance of low energy use and fast curing times.

Future Trends in Fast Curing Coating Technologies

The field of conformal coating curing is evolving rapidly. UV LED technology continues to improve, with systems now achieving higher intensities (up to 2,000 mW/cm2) for even faster curing. Additionally, research into new UV-curable materials promises coatings with enhanced thermal and chemical resistance, potentially increasing dielectric strength beyond current levels.

Automation is another trend to watch. Automated UV curing systems integrated with robotic coating applicators can further reduce human error and speed up production lines, achieving consistent results with minimal downtime.

Conclusion: Optimize Your PCB Production with Fast Curing Solutions

Reducing curing time for conformal coatings is a game-changer in PCB manufacturing, and UV light conformal coating stands out as the best method to cure and reduce curing time for conformal coating. With curing times as low as 5-30 seconds, energy efficiency, and environmental benefits, it’s a powerful tool for high-speed production. However, alternatives like thermal, moisture, and dual-cure systems have their place depending on your specific needs.

By understanding how to use UV light to cure boards fast and weighing the pros and cons of each method, you can streamline your workflow, cut costs, and deliver reliable, protected PCBs to your clients. Whether you’re just starting or looking to upgrade your existing setup, fast curing coating techniques are the key to staying competitive in today’s electronics industry.

ALLPCB

ALLPCB