If you're an electronics hobbyist wondering when to use ENIG finish PCB, the answer lies in your project's needs for durability, solderability, and precision. Electroless Nickel Immersion Gold (ENIG) is a surface finish for printed circuit boards (PCBs) that offers excellent corrosion resistance, a flat surface for fine components, and reliable soldering. It's ideal for projects with complex designs, high reliability requirements, or exposure to harsh environments. In this blog, we'll dive deep into the ENIG benefits for electronics hobbyists and show you how to improve PCB with ENIG finish to elevate your projects.

What is ENIG and Why Should Hobbyists Care?

ENIG stands for Electroless Nickel Immersion Gold, a two-layer surface finish applied to the copper traces of a PCB. The process involves depositing a layer of nickel (typically 3-6 micrometers thick) over the copper, followed by a thin layer of gold (about 0.05-0.1 micrometers). The nickel acts as a barrier to prevent corrosion, while the gold ensures excellent solderability and protects the nickel from oxidation.

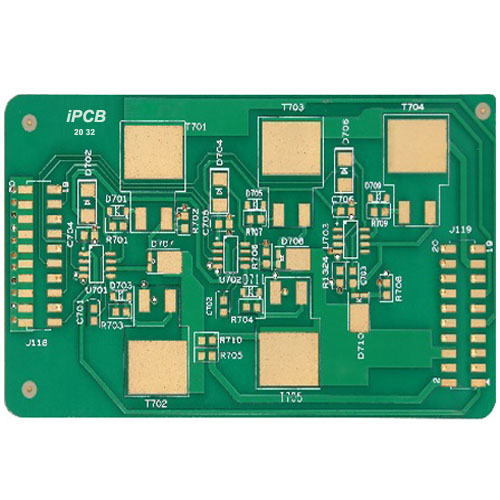

For electronics hobbyists, ENIG is a game-changer. Unlike other finishes like HASL (Hot Air Solder Leveling), which can leave uneven surfaces, ENIG provides a flat, smooth finish. This makes it easier to work with tiny components like surface-mount devices (SMDs) or Ball Grid Arrays (BGAs), which are common in modern hobbyist projects like custom Arduino shields or IoT devices. Plus, ENIG-finished PCBs have a longer shelf life—often up to 12 months without degradation—meaning you can store your boards without worrying about tarnish.

When to Use ENIG Finish on Your PCBs

Choosing the right surface finish for your PCB can make or break your project. Here are specific scenarios where you should consider using ENIG to ensure success.

1. Projects with Fine-Pitch Components

If your design includes fine-pitch components (where the spacing between pins is less than 0.5 mm), ENIG is a must. The flat surface of an ENIG finish ensures that tiny components sit evenly on the board during soldering, reducing the risk of misalignment or poor connections. For example, if you’re building a compact drone controller with SMD chips, ENIG helps achieve precision placement and reliable soldering.

2. High-Reliability Applications

For projects that need to work flawlessly over time—like medical gadgets, weather sensors, or home automation systems—ENIG offers unmatched durability. The nickel layer prevents copper corrosion, even in humid or salty environments. Hobbyists building outdoor projects, such as a solar-powered garden monitor, will find that ENIG extends the life of their PCB compared to cheaper finishes.

3. Boards Exposed to Harsh Conditions

If your PCB will face extreme conditions, such as high humidity or temperature swings, ENIG’s corrosion resistance is a lifesaver. The gold layer protects the board from oxidation, ensuring it remains solderable even after months of storage. Imagine working on a marine electronics project like a boat sensor—ENIG can help your board withstand the salty air without degrading.

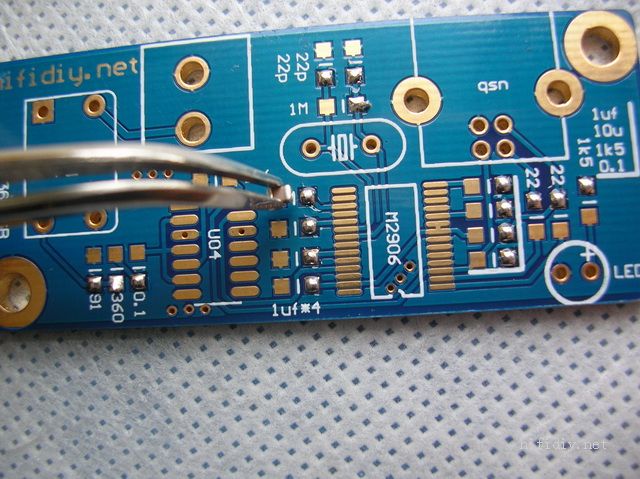

4. Prototyping with Multiple Soldering Cycles

As a hobbyist, you might need to desolder and resolder components during prototyping. ENIG handles multiple soldering cycles without losing its integrity, unlike HASL, which can degrade after repeated heat exposure. This makes ENIG perfect for iterative projects where you’re testing different components, like swapping out resistors on a custom audio amplifier board.

ENIG Benefits for Electronics Hobbyists

Now that you know when to use ENIG, let’s explore the specific ENIG benefits for electronics hobbyists. These advantages can help you decide if the slightly higher cost of ENIG (often $5-10 more per board compared to HASL) is worth it for your project.

1. Superior Solderability

ENIG provides a clean, oxide-free surface that makes soldering a breeze. Whether you’re hand-soldering with an iron or using a reflow oven for SMD components, the gold layer ensures strong, reliable joints. For hobbyists, this means fewer cold solder joints and less frustration during assembly. For instance, when I built a custom LED matrix display, the ENIG finish on my PCB made soldering 0603 LEDs quick and error-free.

2. Flat Surface for Precision

The even surface of ENIG is ideal for placing small components accurately. Unlike HASL, which can leave bumpy solder blobs, ENIG’s uniformity reduces the risk of components tilting or shifting during soldering. This is especially helpful for hobbyists working on intricate designs like Raspberry Pi add-on boards with tight tolerances.

3. Long Shelf Life

ENIG-finished PCBs can sit on your shelf for up to a year without tarnishing, thanks to the protective gold layer. This is a huge plus for hobbyists who might order boards in bulk or delay assembly. I’ve had ENIG boards stored for over 10 months, and they still soldered perfectly when I finally used them for a robotics project.

4. Corrosion Resistance

The nickel layer in ENIG acts as a barrier against corrosion, making it ideal for projects in challenging environments. If you’re experimenting with outdoor electronics, like a weather station, ENIG ensures your board won’t degrade due to moisture or pollutants.

5. Compatibility with Modern Components

Many modern components, like BGAs and QFN packages, require a flat, reliable surface for proper mounting. ENIG meets these needs, making it easier for hobbyists to work with cutting-edge parts. If you’re diving into advanced projects like building a custom gaming handheld with a BGA microcontroller, ENIG gives you the confidence that your connections will hold.

How to Improve PCB with ENIG Finish

Ready to improve PCB with ENIG finish? Here are actionable steps and tips to make the most of this surface finish in your hobbyist projects.

Step 1: Choose ENIG During PCB Ordering

When ordering your PCBs from manufacturers like ALLPCB, look for the surface finish option in the order form. Select ENIG, keeping in mind the slight cost increase (typically $0.50 to $1 per square inch). Most hobbyist-friendly manufacturers offer ENIG as a standard option, and the investment pays off for complex designs.

Step 2: Design with ENIG in Mind

Since ENIG provides a flat surface, you can tighten your design tolerances. For example, reduce pad spacing for fine-pitch components down to 0.4 mm if your soldering skills allow. Use PCB design software like KiCad or Eagle to ensure your layout matches ENIG’s precision capabilities, especially for SMD footprints.

Step 3: Store Boards Properly

Even though ENIG has a long shelf life, store your boards in a dry, cool place to maximize their usability. Use anti-static bags to prevent accidental damage. I’ve found that keeping ENIG boards in a sealed container with silica gel packets helps maintain their condition for over a year.

Step 4: Optimize Soldering Techniques

ENIG’s gold layer solders easily, so avoid overheating during assembly. Use a soldering iron set to 300°C (572°F) for through-hole components and a reflow profile peaking at 245°C for SMDs, as recommended by IPC standards. This prevents damage to the thin gold layer and ensures strong joints.

Potential Downsides of ENIG for Hobbyists

While ENIG offers many benefits, it’s not perfect for every situation. Here are a few drawbacks to consider before choosing this finish.

1. Higher Cost

ENIG is more expensive than HASL or OSP (Organic Solderability Preservative), often adding $5-10 to the cost of small-batch orders. For hobbyists on a tight budget working on simple projects, HASL might be a more economical choice.

2. Not Ideal for Heavy Mechanical Stress

If your project involves frequent plugging and unplugging (like connectors on a test board), the thin gold layer can wear off over time. In such cases, a thicker finish like Hard Gold might be better, though it’s even pricier.

3. Black Pad Risk

In rare cases, improper ENIG application can lead to a defect called “black pad,” where the nickel layer corrodes, causing soldering issues. This is more of a manufacturing quality issue than a hobbyist concern, but it’s worth choosing a reputable PCB supplier to avoid it.

ENIG vs. Other Surface Finishes: A Quick Comparison

To help you decide if ENIG is right for your project, here’s a comparison with other common finishes hobbyists use.

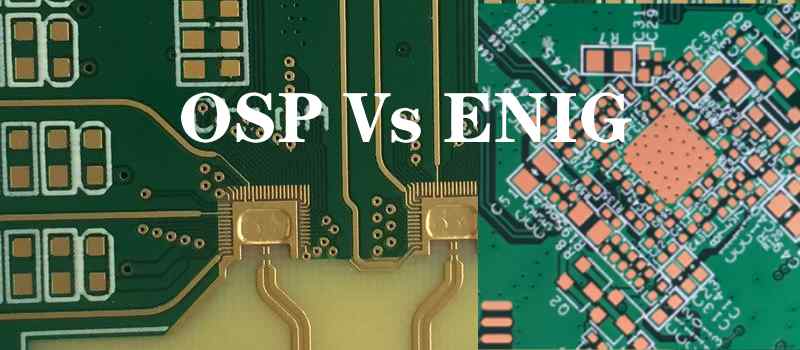

- ENIG vs. HASL: ENIG offers a flatter surface and better corrosion resistance, while HASL is cheaper and suitable for larger components. Use HASL for simple, budget-friendly projects; choose ENIG for precision and durability.

- ENIG vs. OSP: OSP is cheaper and eco-friendly but has a shorter shelf life (6 months) and less corrosion resistance. ENIG is better for long-term storage and harsh environments.

- ENIG vs. Hard Gold: Hard Gold is thicker and better for high-wear areas like connectors, but it’s much more expensive. ENIG is a cost-effective choice for most hobbyist soldering needs.

Real-World Examples from Hobbyists

To give you a clearer picture, here are two real-world scenarios where hobbyists like you benefited from using ENIG.

Example 1: Custom IoT Device

A friend of mine built a Wi-Fi-enabled temperature sensor for his greenhouse. He chose ENIG for the PCB because the device would be exposed to high humidity. After a year of operation, the board showed no signs of corrosion, and the fine-pitch ESP32 module soldered perfectly thanks to the flat surface.

Example 2: Robotics Prototype

During a robotics competition, I used an ENIG-finished PCB for a motor controller. The board went through multiple soldering revisions as I tested different drivers. The ENIG surface held up without degrading, saving me from ordering a new board mid-project.

Final Thoughts: Should You Use ENIG for Your Next Project?

Deciding when to use ENIG finish PCB comes down to your project’s specific needs. If you’re working on a design with fine-pitch components, high reliability demands, or exposure to tough conditions, ENIG is worth the extra cost. The ENIG benefits for electronics hobbyists—like superior solderability, flatness, and corrosion resistance—can significantly improve PCB with ENIG finish and elevate the quality of your work.

For budget-friendly or simple projects, alternatives like HASL might suffice. But for anything complex or long-term, ENIG is a smart investment. Next time you order a PCB, consider how ENIG could enhance your build, and don’t hesitate to ask your manufacturer for advice on finishes.

ALLPCB

ALLPCB