In the fast-evolving world of retail technology, high-resolution displays are becoming the standard for captivating customer experiences. However, designing printed circuit boards (PCBs) for these displays comes with unique hurdles, especially when it comes to maintaining signal integrity. If you're searching for insights on retail display PCB signal integrity, high-speed PCB design, or PCB impedance control for retail displays, you're in the right place. This blog dives deep into the challenges of signal integrity in high-resolution retail display PCBs and offers practical solutions to ensure optimal performance.

What is Signal Integrity and Why Does It Matter for Retail Displays?

Signal integrity refers to the quality and reliability of electrical signals as they travel through a PCB. In high-resolution retail displays, where data rates are high and image quality is critical, even small distortions in signals can lead to flickering screens, data errors, or complete system failures. These displays often operate at high speeds to handle large volumes of data for crisp visuals, making signal integrity a top priority in PCB design.

Maintaining signal integrity ensures that the display functions without glitches, providing a seamless experience for customers in retail environments. Whether it's a digital signage board in a mall or an interactive kiosk in a store, poor signal quality can harm user engagement and brand perception. Let’s explore the specific challenges and solutions in designing PCBs for these applications.

Key Signal Integrity Challenges in Retail Display PCBs

Designing PCBs for high-resolution retail displays involves navigating several obstacles that can degrade signal quality. Below are the primary challenges engineers face:

1. High-Speed Data Transmission

High-resolution displays, such as 4K or 8K screens, require rapid data transmission to refresh images and videos in real time. Data rates often exceed several gigabits per second (Gbps), pushing PCB designs into the realm of high-speed PCB design. At these speeds, signals are more prone to distortion, crosstalk, and timing issues, which can result in visible artifacts on the display.

For instance, a 4K display operating at 60 Hz may require data rates of around 12 Gbps or higher. Without proper design considerations, these high-speed signals can suffer from attenuation, where the signal weakens over long traces, leading to data loss.

2. Crosstalk Between Traces

Crosstalk occurs when signals on adjacent traces interfere with each other, creating noise that disrupts data integrity. In retail display PCBs, where space is often limited and traces are densely packed, crosstalk becomes a significant issue. This is especially true for differential pairs used in high-speed interfaces like HDMI or DisplayPort, which are common in retail displays.

If crosstalk is not managed, it can cause errors in pixel data, leading to distorted images or incorrect colors on the screen. The closer the traces and the higher the frequency, the greater the risk of interference.

3. Impedance Mismatches

Impedance control is critical for maintaining signal integrity, especially in high-speed designs. An impedance mismatch happens when the characteristic impedance of a trace does not match the source or load, causing signal reflections. These reflections can distort the signal, leading to errors in data transmission.

For retail display PCBs, where signals often travel through connectors, vias, and multiple layers, achieving consistent impedance is challenging. A typical target impedance for high-speed signals might be 50 ohms for single-ended traces or 100 ohms for differential pairs. Deviations as small as 10% can introduce noticeable signal degradation.

4. Electromagnetic Interference (EMI)

Retail environments are often filled with electronic devices that can generate electromagnetic interference (EMI). High-speed signals on display PCBs can both emit and be affected by EMI, leading to noise that disrupts signal quality. This is particularly problematic for displays near wireless devices or power sources, as EMI can cause flickering or loss of image clarity.

5. Power Integrity Issues

Signal integrity is closely tied to power integrity. Voltage fluctuations or noise in the power delivery network (PDN) can affect signal quality, especially in high-resolution displays that demand stable power for consistent performance. Inadequate decoupling capacitors or poor grounding can introduce noise into the system, impacting the display’s operation.

Solutions for Signal Integrity in High-Resolution Retail Display PCBs

Overcoming these challenges requires a combination of careful design practices and advanced techniques. Here are actionable solutions to ensure retail display PCB signal integrity in high-speed applications:

1. Optimize Trace Routing for High-Speed Signals

Proper trace routing is essential in high-speed PCB design. Keep trace lengths as short as possible to minimize signal attenuation and delay. For differential pairs, maintain equal lengths to avoid timing skew, which can disrupt data transmission. A skew of just 10 picoseconds in a 10 Gbps signal can cause significant errors.

Additionally, avoid sharp bends in traces, as they can cause signal reflections. Use 45-degree angles or curved traces instead of 90-degree corners to maintain signal quality.

2. Implement PCB Impedance Control for Retail Displays

Achieving PCB impedance control for retail displays starts with selecting the right materials and stack-up. Use controlled impedance traces by calculating the trace width and spacing based on the dielectric constant of the PCB material. For example, a standard FR-4 material with a dielectric constant of 4.5 might require a trace width of 5 mils for a 50-ohm impedance on a specific layer.

Work with your PCB manufacturer to ensure tight tolerances on trace dimensions and material properties. Simulation tools can also help predict and adjust impedance before fabrication, reducing the risk of mismatches.

3. Minimize Crosstalk with Proper Spacing and Shielding

To reduce crosstalk, increase the spacing between high-speed traces, ideally to at least three times the trace width. For differential pairs, keep the traces close to each other but far from other signal lines. Adding ground planes between signal layers can also act as a shield, absorbing unwanted interference.

In retail display PCBs, where board space is often constrained, consider using microstrip or stripline configurations to isolate signals. These layouts help confine electromagnetic fields and reduce crosstalk effectively.

4. Mitigate EMI with Grounding and Filtering

A solid grounding strategy is vital for reducing EMI. Use a continuous ground plane beneath high-speed signals to provide a low-impedance return path. Avoid splitting ground planes, as this can create loops that increase noise. Additionally, place decoupling capacitors close to power pins of ICs to filter out high-frequency noise.

For retail displays in noisy environments, consider adding EMI shielding enclosures around sensitive components. Ferrite beads can also be used on power lines to suppress high-frequency interference.

5. Ensure Power Integrity with a Robust PDN

Design a robust power delivery network by using multiple decoupling capacitors with varying values (e.g., 0.1 μF, 1 μF, and 10 μF) to handle different frequency ranges of noise. Place these capacitors as close as possible to the power pins of high-speed components to minimize voltage drops.

Simulate the PDN during the design phase to identify potential issues like resonance or insufficient current capacity. A well-designed PDN ensures stable power, which directly supports signal integrity.

Advanced Techniques for High-Speed PCB Design in Retail Displays

Beyond the basics, there are advanced strategies that can further enhance signal integrity in retail display PCBs:

1. Use of Simulation Tools

Signal integrity simulation tools allow engineers to model and analyze signal behavior before manufacturing. These tools can predict issues like crosstalk, reflections, and EMI, enabling designers to make adjustments early. For high-resolution displays, simulating data rates of 10 Gbps or higher can reveal potential bottlenecks in the design.

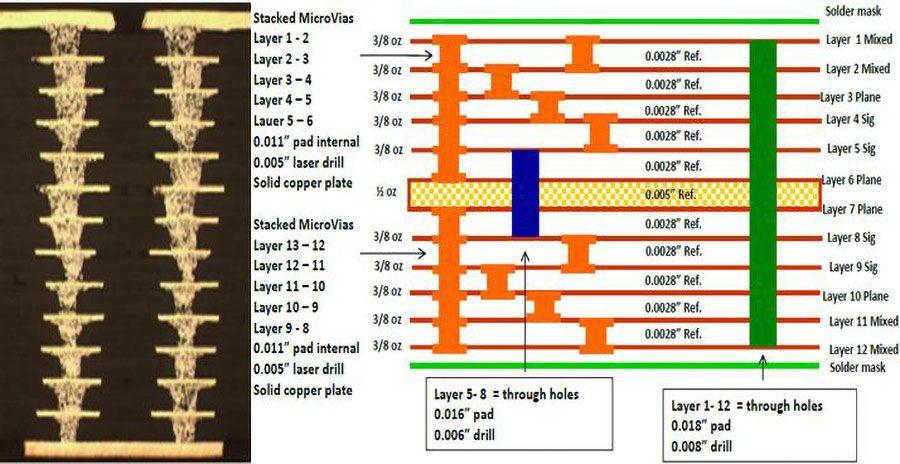

2. Backdrilling for Via Stub Reduction

In multilayer PCBs, vias can create stubs that cause signal reflections. Backdrilling removes unused portions of vias to minimize these stubs, improving signal quality at high frequencies. This technique is especially useful for retail display PCBs with dense layouts and multiple layers.

3. Material Selection for High-Speed Performance

Standard FR-4 materials may not suffice for very high-speed signals due to their higher dielectric loss. Consider using low-loss materials like Rogers or Isola for frequencies above 5 GHz. These materials reduce signal attenuation and support better impedance control, critical for retail display applications.

Conclusion: Mastering Signal Integrity for Retail Display Success

High-resolution retail displays are transforming the way businesses engage with customers, but their performance hinges on the signal integrity of the underlying PCBs. Challenges like high-speed data transmission, crosstalk, impedance mismatches, EMI, and power integrity can compromise display quality if not addressed. By adopting best practices such as optimized trace routing, PCB impedance control for retail displays, and robust grounding, engineers can overcome these hurdles and ensure flawless operation.

At ALLPCB, we understand the intricacies of high-speed PCB design and are committed to supporting your retail display projects with precision manufacturing and expert guidance. Whether you're tackling signal integrity issues or optimizing for high-resolution performance, our team is ready to help you bring your vision to life with reliable, high-quality PCBs.

By focusing on these strategies, you can build retail display systems that not only meet technical demands but also deliver stunning visuals that captivate audiences. Stay ahead in the competitive retail landscape by prioritizing retail display PCB signal integrity in every design.

ALLPCB

ALLPCB