In the fast-evolving world of electronics, managing heat in printed circuit boards (PCBs) is crucial for performance and reliability. How can you ensure your PCBs stay cool under pressure? By leveraging advanced techniques like laser drilling for thermal vias and adopting smart thermal management strategies. In this comprehensive guide, we’ll explore how laser drilling enhances thermal vias, the importance of PCB thermal management, and effective ways to achieve heat dissipation in PCBs. Whether you're designing high-power systems or compact devices, these insights will help you keep your boards efficient and durable.

Why Thermal Management Matters in PCB Design

Heat is the silent enemy of electronic components. When a PCB operates, components like processors, power transistors, and LEDs generate heat that, if not managed, can lead to performance degradation, shortened lifespan, or complete failure. Studies show that for every 10°C rise in temperature, the lifespan of electronic components can be halved. Effective PCB thermal management isn’t just a nice-to-have—it’s a necessity for modern, high-performance electronics.

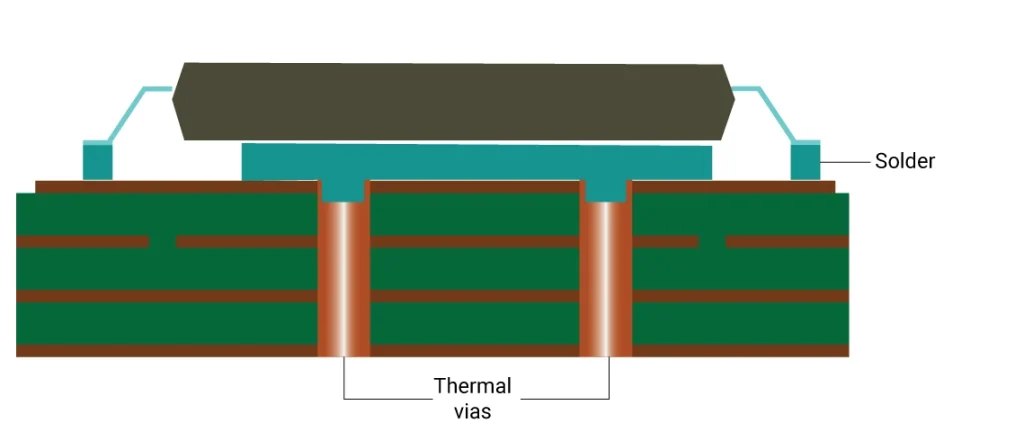

Thermal management involves strategies to transfer heat away from critical components and dissipate it safely. This is where thermal vias, often created through laser drilling, play a pivotal role. They act as conduits for heat, moving it from hot spots to heat sinks or other cooling mechanisms. Let’s dive into how laser drilling makes this possible and why it’s a game-changer for heat dissipation in PCBs.

What Are Thermal Vias and Why Are They Important?

Thermal vias are small, vertical pathways in a PCB that conduct heat from one layer to another, typically from a heat-generating component to a ground plane or heat sink. Unlike electrical vias, which connect signals between layers, thermal vias are dedicated to heat transfer. They create a low-resistance path for heat to escape, preventing dangerous temperature buildups.

In high-power applications, such as LED lighting or power amplifiers, thermal vias can reduce component temperatures by as much as 20-30°C, depending on the design. Their placement, size, and quantity directly impact their effectiveness. For instance, a densely packed array of thermal vias under a high-power component can significantly lower thermal resistance, often achieving values as low as 1-2°C/W in well-designed boards.

Creating these vias with precision is critical, and this is where laser drilling shines. Traditional mechanical drilling struggles with the small diameters and high precision needed for modern microvias used in thermal management. Laser drilling, on the other hand, offers unmatched accuracy and flexibility, making it ideal for crafting thermal vias in compact, high-density designs.

Laser Drilling Thermal Vias: Precision for Better Heat Dissipation

Laser drilling is a cutting-edge manufacturing technique that uses focused laser beams to create small, precise holes in PCB materials. When it comes to crafting thermal vias for heat dissipation in PCBs, laser drilling offers several advantages over traditional methods:

- High Precision: Laser drilling can create microvias with diameters as small as 3-6 mils (0.075-0.15 mm), allowing for dense arrays of thermal vias in tight spaces.

- Material Flexibility: It works effectively on a variety of substrates, including FR-4, ceramics, and flexible materials, without causing damage like cracking or delamination.

- Speed and Efficiency: Laser systems can drill thousands of vias per minute, accelerating production timelines for complex boards.

- Customizable Depth: Laser drilling supports blind and buried vias, which are essential for multilayer PCBs where heat needs to be channeled to specific internal layers.

For microvia heat transfer, laser-drilled vias are often filled with conductive materials like copper to enhance thermal conductivity. A typical copper-filled microvia can achieve a thermal conductivity of around 400 W/m·K, far superior to unfilled vias or those filled with less conductive materials. This ensures efficient heat transfer from hot components to cooling layers or external heat sinks.

PCB Thermal Management: Strategies Beyond Thermal Vias

While laser-drilled thermal vias are a powerful tool for heat dissipation in PCBs, they’re just one part of a broader thermal management strategy. To keep your boards cool and efficient, consider integrating these complementary approaches:

1. Material Selection for Better Heat Conductivity

The choice of PCB substrate material greatly affects thermal performance. Standard FR-4 materials have a thermal conductivity of about 0.3 W/m·K, which is insufficient for high-power applications. High-thermal-conductivity materials, such as metal-core PCBs (MCPCBs) or ceramics, can offer values up to 170 W/m·K, making them ideal for dissipating heat. For example, aluminum-backed PCBs are commonly used in LED lighting to manage heat effectively.

2. Ground Planes and Heat Sinks

Large copper ground planes act as natural heat spreaders, distributing thermal energy across the board. Connecting thermal vias to these planes enhances their effectiveness. External heat sinks, often made of aluminum or copper, can be attached to the PCB to further dissipate heat into the surrounding environment. In some designs, heat sinks combined with thermal vias can reduce component temperatures by up to 40%.

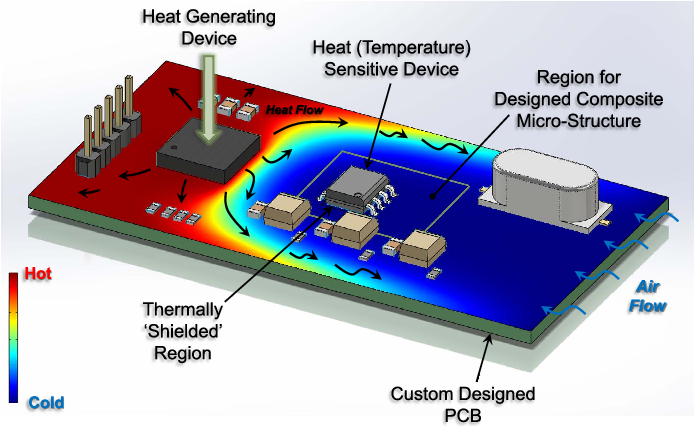

3. Component Placement and Layout Optimization

Strategic placement of heat-generating components can minimize thermal hotspots. Place high-power components near thermal vias or heat sinks and avoid clustering them in one area. Additionally, ensure adequate spacing for airflow if active cooling (like fans) is part of the system. Simulation tools can predict thermal behavior, helping designers optimize layouts before production.

4. Active Cooling Solutions

For extremely high-power systems, passive cooling via thermal vias and heat sinks may not be enough. Active cooling methods, such as fans or liquid cooling systems, can be integrated. While these add complexity and cost, they’re essential for applications like server boards or gaming hardware where heat loads can exceed 100W per component.

Microvia Heat Transfer: Challenges and Solutions

Microvias, small vias often created through laser drilling, are increasingly used in high-density interconnect (HDI) PCBs for both electrical and thermal purposes. Their small size—typically less than 0.15 mm in diameter—makes them perfect for compact designs, but it also introduces challenges for microvia heat transfer:

- Limited Thermal Capacity: Due to their small cross-sectional area, microvias have less capacity to conduct heat compared to larger vias. To overcome this, designers often use arrays of microvias to increase the total heat transfer area.

- Manufacturing Precision: Misalignment or inconsistent plating in microvias can reduce thermal conductivity. Laser drilling ensures precision, and advanced plating techniques can maintain consistent copper thickness, often around 1 mil (0.025 mm), inside the vias.

- Cost Considerations: Laser-drilled microvias are more expensive to produce than standard through-hole vias. However, their benefits in heat dissipation and space-saving often justify the cost in high-performance applications.

By addressing these challenges, microvias can significantly enhance heat dissipation in PCBs, especially in multilayer and HDI designs where space is at a premium.

Best Practices for Designing Thermal Vias with Laser Drilling

To maximize the effectiveness of laser-drilled thermal vias in your PCB thermal management strategy, follow these design tips:

- Optimize Via Placement: Position thermal vias directly under or near heat-generating components to minimize thermal resistance. For a component dissipating 5W of heat, placing 10-15 vias in a grid pattern can effectively lower temperatures.

- Determine Via Size and Count: Smaller microvias save space but may require more in number to achieve the same heat transfer as larger vias. Use thermal simulation tools to find the right balance.

- Fill Vias with Conductive Material: Copper-filled vias offer superior thermal conductivity compared to unfilled ones. This is especially important for microvia heat transfer in high-density boards.

- Connect to Large Copper Planes: Ensure thermal vias connect to substantial copper areas, like ground planes, to spread heat effectively across the board.

- Collaborate with Manufacturers: Work closely with your PCB fabrication partner to ensure laser drilling capabilities align with your design needs, especially for microvias in complex multilayer boards.

The Future of PCB Thermal Management

As electronics continue to shrink in size while increasing in power, the demand for advanced thermal management solutions will only grow. Laser drilling technology is evolving, with newer systems offering even greater precision and speed for creating thermal vias. Innovations like 3D-printed heat sinks and advanced composite materials with ultra-high thermal conductivity (exceeding 500 W/m·K) are also on the horizon, promising to revolutionize heat dissipation in PCBs.

Moreover, the integration of artificial intelligence in PCB design tools is making it easier to simulate and optimize thermal performance before fabrication. These tools can predict how microvia heat transfer will perform under various conditions, reducing the need for costly redesigns.

Conclusion: Keeping Your PCBs Cool with Laser Drilling and Thermal Management

Effective PCB thermal management is essential for ensuring the reliability and performance of modern electronics. Laser drilling thermal vias offers a precise, efficient way to create pathways for heat dissipation in PCBs, especially in compact, high-density designs. By combining thermal vias with other strategies—such as optimal material selection, strategic component placement, and the use of heat sinks—you can keep your boards cool and efficient even under demanding conditions.

At ALLPCB, we’re committed to supporting your thermal management needs with state-of-the-art fabrication techniques, including laser drilling for microvias and thermal vias. Whether you’re working on high-power systems or miniature devices, our expertise ensures your PCBs perform at their best. Start designing with heat dissipation in mind, and let advanced technologies keep your electronics running smoothly.

ALLPCB

ALLPCB