Designing a printed circuit board (PCB) for USB interfaces can be challenging, but with the right approach, you can ensure reliable data transfer. Whether you're working on a USB 2.0, USB 3.0, or even USB-C project, key factors like USB trace impedance, differential pair routing for USB, connector selection, minimizing signal reflections, and proper USB PCB layout play a critical role. In this comprehensive guide, we'll walk you through the essential steps and best practices to create a robust USB interface design that performs flawlessly.

Why USB Interface Design Matters for Reliable Data Transfer

USB interfaces are everywhere—from smartphones and laptops to industrial equipment and IoT devices. They provide a universal way to connect devices and transfer data at high speeds. However, poor PCB design can lead to signal degradation, data loss, or even device failure. Issues like improper impedance matching or signal reflections can disrupt communication between devices. By focusing on critical design aspects like trace routing and connector choice, you can avoid these pitfalls and ensure consistent performance.

In the sections below, we’ll dive deep into each element of USB PCB design, offering practical tips and specific guidelines to help you succeed.

Understanding USB Standards and Their Design Requirements

Before starting your PCB design, it’s important to know which USB standard you're targeting. Each version has unique requirements for data transfer speed and signal integrity:

- USB 2.0: Supports speeds up to 480 Mbps. It uses a differential pair for data (D+ and D-) and requires careful impedance control, typically around 90 ohms for differential traces.

- USB 3.0/3.1: Offers speeds up to 5 Gbps (Gen 1) or 10 Gbps (Gen 2). It introduces additional differential pairs for SuperSpeed data transfer, demanding stricter impedance matching and shorter trace lengths.

- USB-C: A versatile connector supporting USB 2.0, 3.0, and even higher standards like Thunderbolt. It requires precise routing due to its compact size and high-speed capabilities.

Each standard affects your PCB layout decisions, from stackup design to trace width. Keep the specific requirements of your chosen USB version in mind as you proceed.

Key Factor 1: USB Trace Impedance for Signal Integrity

One of the most critical aspects of USB PCB design is maintaining the correct USB trace impedance. Impedance mismatch can cause signal reflections, leading to data errors or reduced transfer speeds. For USB interfaces, the differential impedance of the D+ and D- lines should typically be 90 ohms (±10%) for USB 2.0 and tighter tolerances for higher-speed standards like USB 3.0.

To achieve this, consider the following during your design:

- Trace Width and Spacing: Use a PCB impedance calculator to determine the exact width and spacing of your differential traces based on your board’s dielectric material and thickness. For a standard FR-4 material with a dielectric constant of 4.2, a trace width of about 8 mils and spacing of 6 mils might work for a 90-ohm differential pair on a 2-layer board.

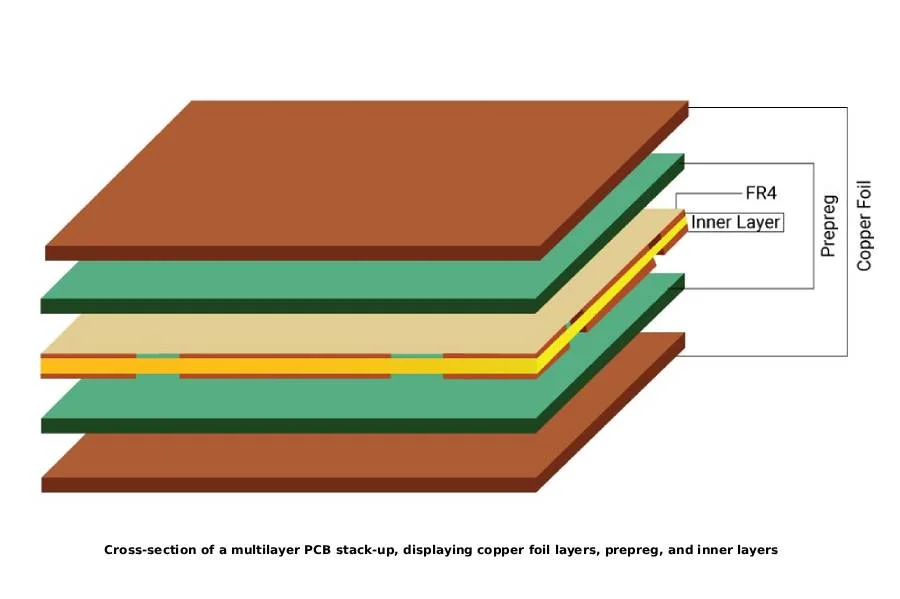

- Stackup Design: For high-speed USB designs (USB 3.0 and above), a 4-layer or higher stackup is recommended. Place signal traces on the top layer with a solid ground plane beneath to control impedance and reduce noise.

- Material Choice: The PCB material impacts impedance. Standard FR-4 is fine for USB 2.0, but for USB 3.0 and beyond, consider low-loss materials to minimize signal attenuation.

By carefully controlling USB trace impedance, you lay the foundation for reliable data transfer across your interface.

Key Factor 2: Differential Pair Routing for USB

USB data lines operate as differential pairs, meaning the D+ and D- signals are transmitted together and must be routed with precision. Proper differential pair routing for USB ensures that both traces experience the same electrical environment, minimizing noise and signal skew.

Here are some best practices for routing differential pairs:

- Length Matching: Keep the lengths of D+ and D- traces as equal as possible. For USB 2.0, a mismatch of less than 150 mils is generally acceptable, but for USB 3.0, aim for less than 15 mils to avoid timing issues at higher speeds.

- Consistent Spacing: Maintain consistent spacing between the two traces to ensure uniform impedance. Avoid sudden changes in spacing or routing near other high-speed signals.

- Avoid Vias: Minimize the use of vias on differential pairs, as they introduce impedance discontinuities. If vias are unavoidable, use back-drilling or keep them symmetrical for both traces.

- Ground Plane: Route differential pairs over a continuous ground plane to reduce electromagnetic interference (EMI) and provide a stable return path.

Following these guidelines helps maintain signal integrity, especially at higher data rates.

Key Factor 3: Connector Selection for USB Interfaces

Choosing the right USB connector is just as important as trace routing. The connector impacts not only the physical connection but also signal quality and durability. With options like Type-A, Type-B, Micro-USB, and USB-C, your selection depends on the application and USB standard.

Consider these factors when selecting a USB connector:

- USB Version Compatibility: Ensure the connector supports the USB standard you're using. For example, USB-C connectors are ideal for modern designs due to their support for USB 2.0, 3.0, and beyond, along with reversible insertion.

- Physical Size: For compact devices, smaller connectors like Micro-USB or USB-C are better. For industrial applications, a sturdier Type-A or Type-B might be more suitable.

- Durability: Look at the connector’s mating cycle rating. USB-C connectors often support up to 10,000 cycles, making them durable for frequent use.

- Signal Pins: Higher-speed standards like USB 3.0 require additional pins for SuperSpeed data lines. Verify that the connector supports all necessary signals for your design.

A well-chosen connector ensures a reliable physical and electrical connection, reducing the risk of data transfer issues.

Key Factor 4: Minimizing Signal Reflections in USB Design

Signal reflections occur when there’s an impedance mismatch along the signal path, causing part of the signal to bounce back and interfere with the original transmission. Minimizing signal reflections is crucial for maintaining data integrity in USB interfaces.

Here’s how to tackle this issue:

- Impedance Continuity: As mentioned earlier, maintain consistent USB trace impedance throughout the signal path, including at connectors and terminations.

- Termination Resistors: For USB 2.0, the host and device often handle termination internally, but for custom designs, ensure proper termination resistors are in place if required by the chipset.

- Avoid Sharp Corners: Route traces with smooth, gradual bends (45-degree angles or curves) rather than sharp 90-degree turns to prevent reflections.

- Connector Placement: Place the USB connector as close as possible to the controller IC to minimize trace length and potential reflection points.

By addressing these areas, you can significantly reduce signal reflections and improve overall performance.

Key Factor 5: Best Practices for USB PCB Layout

A well-thought-out USB PCB layout ties all the above elements together. The layout directly impacts signal integrity, noise levels, and EMI. Follow these best practices to create an effective USB PCB layout:

- Short Trace Lengths: Keep USB data traces as short as possible to reduce signal delay and attenuation. For USB 3.0, trace lengths should ideally be under 4 inches.

- Power and Ground Planes: Dedicate separate layers or areas for power (Vbus) and ground to provide stable voltage and a low-impedance return path. Place decoupling capacitors (e.g., 0.1 μF and 1 μF) near the USB controller IC to filter noise.

- Isolation from Noise Sources: Route USB traces away from high-frequency components like switching regulators or clock signals to avoid crosstalk.

- Shielding: For USB connectors, ensure proper grounding of the shield to reduce EMI. Connect the shield to the ground plane through multiple vias for better performance.

A clean and organized USB PCB layout minimizes potential issues and ensures reliable data transfer.

Common Challenges in USB PCB Design and How to Overcome Them

Even with careful planning, USB PCB design can present challenges. Here are a few common issues and solutions:

- EMI Interference: High-speed USB signals can generate or be affected by EMI. Use shielding, proper grounding, and ferrite beads on power lines to mitigate this.

- Space Constraints: In compact designs, fitting USB traces and connectors can be tough. Prioritize short, direct routing and consider smaller connectors like USB-C.

- Signal Skew: Mismatched trace lengths in differential pairs cause skew. Use PCB design software with length-matching tools to keep traces equal.

Addressing these challenges early in the design process saves time and prevents costly revisions.

Testing and Validation of Your USB PCB Design

Once your PCB is designed and manufactured, testing is essential to confirm reliable data transfer. Use these methods to validate your design:

- Signal Integrity Testing: Use an oscilloscope to check for signal reflections, jitter, or noise on the USB data lines. Ensure the eye diagram meets the USB specification for your chosen standard.

- Impedance Measurement: Use a time-domain reflectometer (TDR) to verify that the differential impedance of your traces matches the target (e.g., 90 ohms for USB 2.0).

- Functional Testing: Connect your device to various USB hosts and peripherals to confirm data transfer rates and compatibility.

Thorough testing helps catch issues before they impact end users, ensuring a high-quality product.

Conclusion: Building Reliable USB Interfaces with Proper PCB Design

Designing a PCB for USB interfaces requires attention to detail, from USB trace impedance and differential pair routing for USB to connector selection, minimizing signal reflections, and optimizing USB PCB layout. By following the guidelines and best practices outlined in this guide, you can create a design that ensures reliable data transfer across a wide range of applications.

Start with a clear understanding of the USB standard you're targeting, then focus on impedance control, precise routing, and careful component selection. With a well-planned layout and thorough testing, your USB interface will deliver consistent performance, whether it’s for a consumer gadget or an industrial system.

At ALLPCB, we’re committed to supporting engineers with the tools and resources needed for successful PCB designs. Apply these principles to your next project, and you’ll be well on your way to creating robust and efficient USB interfaces.

ALLPCB

ALLPCB