The global rise of clean energy and energy storage systems is accelerating, driven by the adoption of renewable energy and the growth of electric vehicles. Energy storage printed circuit boards (PCBs) are critical components in these systems, managing connections, control, and protection of battery systems to ensure performance and reliability. This article explores essential considerations for designing and manufacturing energy storage PCBs to meet the demands of this growing market.

Material Selection and Sustainability

Material selection is a cornerstone of energy storage PCB design. Opt for environmentally friendly materials that comply with RoHS standards to minimize environmental impact. Materials must also offer high thermal and chemical stability to ensure reliable operation under diverse conditions. Choosing sustainable materials supports the long-term viability of energy storage systems.

PCB Layer Structure Design

Multilayer PCB designs are recommended to provide additional routing and ground layers. This approach reduces resistance, inductance, and noise while enhancing interference resistance. In energy storage systems, stable signal transmission is critical, making thoughtful layer structure design essential.

Thermal Management

High currents in energy storage PCBs can generate significant heat, necessitating effective thermal management. Incorporate heat sinks or radiators to prevent overheating. Selecting materials with high thermal conductivity is also crucial to efficiently transfer and dissipate heat, maintaining safe operating temperatures.

High-Current Design

Energy storage systems often handle high currents, requiring careful planning of current pathways to minimize resistance and inductance. Increase copper thickness, widen traces, and shorten current paths to achieve this. Use adequately sized pads and vias to support high-current connections and ensure stable transmission.

Electromagnetic Compatibility (EMC)

EMC is a critical consideration in energy storage PCB design. Implement shielding and filtering techniques to reduce electromagnetic interference, ensuring stable system operation and compatibility with other electronic devices.

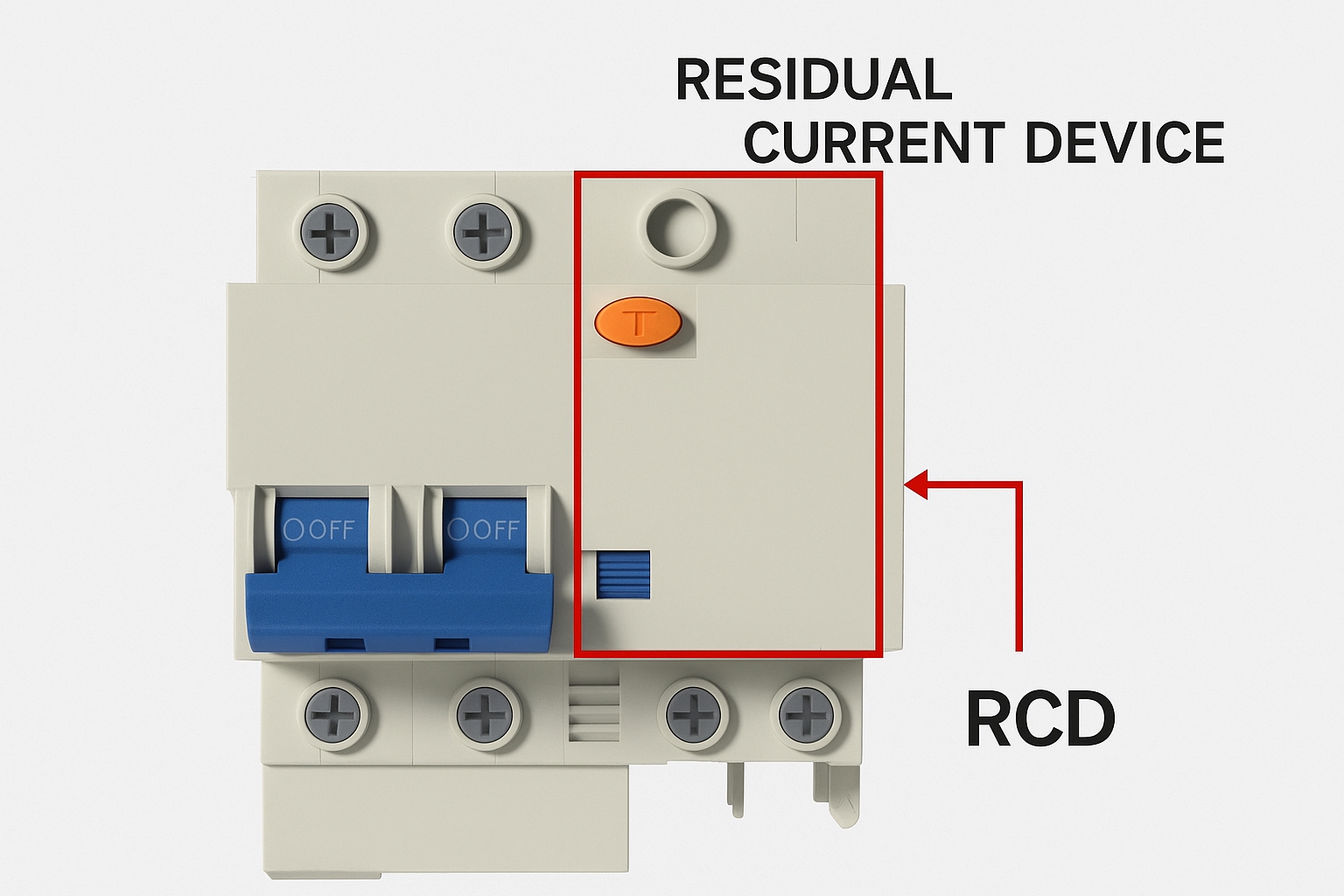

Safety

Given the large-capacity batteries in energy storage systems, safety is paramount. Integrate multiple protection mechanisms, such as overvoltage, overcurrent, and temperature monitoring. Safety switches and circuit breakers on the PCB are essential to quickly disconnect power during faults, protecting both the system and operators.

Maintainability

Energy storage systems require long-term reliability, making PCB maintainability vital. Adopt modular designs to facilitate easier replacement or repair. Optimize component layouts to allow convenient access for maintenance, reducing downtime.

Automated Manufacturing

Automation in PCB manufacturing enhances production efficiency and consistency while minimizing human error. Prioritize automated processes to ensure high-quality output for energy storage PCBs.

Testing and Validation

Comprehensive testing and validation are crucial. Conduct prototype, electrical performance, and reliability tests to verify PCB stability and performance, ensuring they meet the rigorous demands of energy storage applications.

In summary, designing and manufacturing energy storage PCBs requires careful attention to material selection, layer structure, thermal management, high-current design, EMC, safety, maintainability, automation, and testing. Adhering to these principles ensures reliable and high-performing PCBs, supporting the global transition to sustainable energy solutions.

ALLPCB

ALLPCB